Experiment results and process:

In last week’s class we learned how to use the wood cutter. We learned that when compared to the laser cutter, its advantage is that it is useful for cutting larger chunks of wood. An IMA fellow showed us how to use the slicer software and vector software Rhino to create the design, which we wish to cut out and then send it to the woodcutter for printing. I learned that this is a rather fast but noisy process and will most likely not use this machine for my final project. However, I will be using the laser cutter to create a sign for my final project.

The wood cutter is to be used in the process of creating the stool, which we started a couple of classes ago. We learned that we had to cut out specific pieces to make them fit together and then measure them in an accurate way so that there is enough space between the pieces. The wood must also be kept firmly in place by the supports of the machine, so as to prevent it from becoming dislodged during the cutting.

Plastic alternative updates:

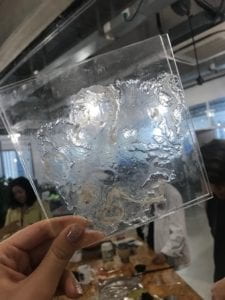

As for the update on our previous project with the potato starch, the project is rather disappointing since we did not heat it at the right temperature and the mixture was firm and burnt at some places and then soft and sticky at others. My partner Eva and I decided to replicate the project with the right measurements of both glycerol and the heating duration, during the coming week.

Leave a Reply