Experiment and results from workshop:

Last class, we had a guest speaker from Precious Plastics Shanghai. She was one of the co-founders of the organization that upcycles plastics and uses donations from citizens to create new products from plastic, in order to give them a new life. We had a talk about the work of the company and the different types of plastic. We learned that the best type of plastic for recycling is type 2 plastic, and there are certain types of plastics that we should avoid melting, as we do not know how they will react when heated. The plastic that we must never melt is PVC as this plastic burns and could cause damage if inhaled. We learned that type 2 and 4 are all plastic bags and plastic juice and milk bottles, as well as bottle caps.

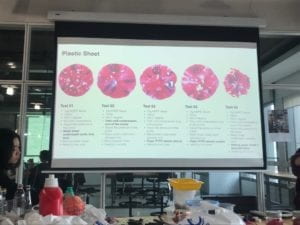

The guest speaker also explained the various machines they have in the lab for melting plastics such as a heat press, shredder, bike-propelled shredder and a machine that specializes in creating spinning tops out of melted recycled plastic. We also talked about the multiple tests that her team does to find the right consistency for their plastic projects. They did a total of 5 tests on melted plastic shreddings and pellets to find that depending on the kind of the baking paper used in the melting, as well as the length of heating and heating temperature, there were different results to the plastic outcome. Sometimes the plastic came out malleable and glossy, and sometimes it had a marble-like structure and was rather rough to the touch.

The guest speaker and professor Godoy then showed us how to create the plastic products such as bowls and plates through melting and heat pressing. We first cut up plastic bags and detergent and juice bottles and then inserted them in the shredder. After using the shredder, we obtained tiny plastic shavings which we placed on the heat press between 2 pieces of baking paper. one of the baking sheets had a glossy finish and the other had a matte feature. After 10 mins at around 170 degrees, we removed the melted plastic and pressed it together and left it to cool down.

After we removed the plastic from the heat press, we saw that one sample was glossy and the other was matte. We concluded that if the plastic is left to cool longer, the result is better.

We also used plastic shredding and pellets which Marcela and the speaker had from before and put it in a metal mold baking pan which we put in the oven. When we removed the pan from the oven, we were left with a soft think sheet of plastic. Due to the class time ending, we were not able to complete the stool creation process, which we will resume next class.

Readings notes:

The Truth About Bioplastics:

- The world has produced over nine billion tons of plastic since the 1950s.

- 165 million tons of it have trashed our ocean.

- Almost 9 million more tons entering the oceans each year.

- Traditional plastic is made from petroleum-based raw materials. Some say bioplastics—made from 20 percent or more of renewable materials—could be the solution to plastic pollution.

- The often-cited advantages of bioplastic are reduced use of fossil fuel resources, a smaller carbon footprint, and faster decomposition.

- Bioplastic is also less toxic and does not contain bisphenol A (BPA), a hormone disrupter that is often found in traditional plastics.

- Degradable – All plastic is degradable, even traditional plastic, but just because it can be broken down into tiny fragments or powder does not mean the materials will ever return to nature.

- Biodegradable – Biodegradable plastic can be broken down completely into water, carbon dioxide and compost by microorganisms under the right conditions

- Compostable – Compostable plastic will biodegrade in a compost site.

- The global bioplastic market is projected to grow from $17 billion this year to almost $44 billion in 2022.

There are two main types of bioplastics.

- PLA (polyactic acid) is typically made from the sugars in corn starch, cassava or sugarcane. It is biodegradable, carbon-neutral and edible.

PLA can look and behave like polyethylene (used in plastic films, packing and bottles), polystyrene (Styrofoam and plastic cutlery) or polypropylene (packaging, auto parts, textiles).

- PHA (polyhydroxyalkanoate) is made by microorganisms, sometimes genetically engineered, that produce plastic from organic materials.

- While bioplastics are generally considered to be more eco-friendly than traditional plastics, a 2010 study from the University of Pittsburgh found that wasn’t necessarily true when the materials’ life cycles were taken into consideration.

- The researchers determined that bioplastics production resulted in greater amounts of pollutants, due to the fertilizers and pesticides used in growing the crops and the chemical processing needed to turn organic material into plastic.

- The bioplastics also contributed more to ozone depletion than the traditional plastics, and required extensive land use.

- Bioplastics do produce significantly fewer greenhouse gas emissions than traditional plastics over their lifetime.

- A 2017 study determined that switching from traditional plastic to corn-based PLA would cut U.S. greenhouse gas emissions by 25 percent.

- While the biodegradability of bioplastics is an advantage, most need high temperature industrial composting facilities to break down and very few cities have the infrastructure needed to deal with them.

- When bioplastics are not discarded properly, they can contaminate batches of recycled plastic and harm recycling infrastructure.

- The land required for bioplastics competes with food production because the crops that produce bioplastics can also be used to feed people.

- Bioplastics are also relatively expensive; PLA can be 20 to 50 percent more costly than comparable materials because of the complex process used to convert corn or sugarcane into the building blocks for PLA.

- If you integrate wastewater treatment or address food waste challenges with bioplastic production, then this is quite favorable [economically]

- Chandran hopes to close the loop so that, one day, waste products will routinely serve as a resource that can be converted into useful products like bioplastic.

- Full Cycle Bioplastics in California is also producing PHA from organic waste such as food waste, crop residue such as stalks and inedible leaves, garden waste, and unrecycled paper or cardboard.

- Stanford University researchers and California-based startup Mango Materials are transforming methane gas from wastewater treatment plants or landfills into bioplastic.

- Pennsylvania-based Renmatix is utilizing woody biomass, energy grasses and crop residue instead of costlier food crops.

- Japanese design company AMAM is producing packaging materials made from the agar in red marine algae.

- The U.S. Department of Agriculture is developing a biodegradable and edible film from the milk protein casein to wrap food in; it is 500 times better at keeping food fresh than traditional plastic film.

Final Project Ideas:

- A product that is a substitute for rope or marble or clothing that uses materials that would otherwise be discarded.

- A packaging material that is made from recycled materials, and which can be reused, as a way to decrease the amount of packaging that is used for food delivery and product delivery in Shanghai.

I aim to find out if there exists a material that can be made from recycled plastic bags or bottles or thread, which can be given a new life and used to reduce the need for the production of new materials.

I am proposing this project, because I notice the immense amount of waste produced on a daily basis in Shanghai and other Chinese cities, due to the large amount of online orders and excessive packaging used to transport the products. I believe that this idea could create a new market mechanism that will decrease the amount of waste produced by consumers daily and provide a cost-effective solution for businesses. If I am able to create this alternative, I will significantly reduce the amount of trash per person in Shanghai and other major Chinese cities. My hyphotesis aims to test whether such an alternative already exists, what would its costs of production be, and whether it is a viable option that will attract the attention and positive reception by brands.

Leave a Reply