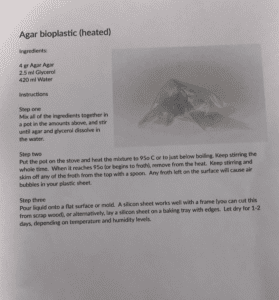

For this week’s lecture, we were divided up into groups to make different kinds of bioplastics. Our group, consisting of me, James and Joyce, were in charge of creating bioplastics out of agar, glycerin and water.

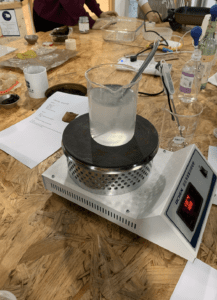

The process of it was simple and straightforward enough. We combined all the ingredients together then heated this up to 95 degrees Celsius, stirring all the way through the whole process. Then poured thinly onto a tray to dry for a couple of days. We found that this method of making bioplastic is extremely easy, but also extremely time-consuming. At the end of class, we were not able to get our agar solution to 95 degrees, just 70 degrees. We have yet to see how this might have affected our bioplastic.

From this experiment, I was excited by the thought of this new, innovative alternative for plastic. Yet, I also wondered why this is still not often used or produced by companies as there is already some solid research on these bioplastics. It wasn’t until I read “The truth about bioplastics” that I realised there were still a lot of unresolved problems. For example, although bioplastics are still much better than regular plastic, it still needs high temperatures in specific composting facilities in order to break down. This required investment in these specific composting facilities and many countries do not have the money or the resources for this — creating a barrier for poor, developing countries.

Moreover, there is also the issue of many of the bioplastics still emitting greenhouse gases as it involves the production of crops. It would also be competing with the food industry and would need vast amounts of land in order to produce the crops. From this article, it is clear why these bioplastics are not able to be fully manufactured in a large scale as further research still needs to be done.

Leave a Reply