Re-Frisbee

Sofia Shockman & Eva Solo

Part 1: Brainstorming

For my final project, I wanted to focus on the youth of Shanghai. I was inspired by the video Marcela showed us in class that depicted the kids who brought their toys to a plastic shredding machine and then produced new material to make a new product. Childhood is a definitive moment in life that has the potential to shape tendencies for the rest of the individuals’ life. So I think that part of the experience of learning about this course and how we can actually make an impact can start at the beginning stages of life in order to create habits and a lifestyle for future generations.

I toyed around with the idea to create a lego set out of recycled plastic. Lego is already creating sustainable building blocks and it is a company that is almost run 100% ethically in terms of material sourcing and employee treatment. This seemed like a great idea, but the downside was creating molds to make the lego pieces because it would have been at least 5 different molds or else it defeats the purpose of making legos if they only come in one shape. I also wanted to host a workshop that could educate children in Shanghai by telling them to bring in their old plastic toys and plastic waste laying around the house and we would then shred it, stick it in the premade molds and then heat it up.

Then, I began talking to my classmates and it wasn’t until Eva told me that she was also interested in working with some sort of children product that we came across a frisbee from Patagonia that is made out of 15% recycled plastic. We wanted to challenge that and do a disc out of 100% recycled plastic. Thus we took on a project that we named: Re-Frisbee.

Part 2: Begin ideation and experimentation

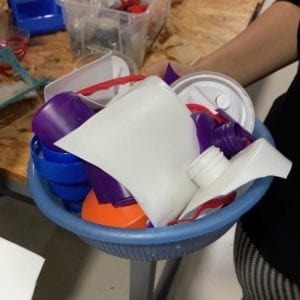

We began on our journey to construct a frisbee made out of 100% recycled plastic with the intent of children to use in mind. We first began by gathering products together. We used plastic #2 (high-density polyethylene HDPE) and #4 (low-density polyethylene LDPE). We collected many water bottle caps, soap bottles, plastic grocery bags, squeezable bottles, clear colored bottles, milk jugs, detergent bottles, juice bottles, and toiletries. We deconstructed many water bottles to take the top part off that is a different plastic from the whole rest of the water bottle.

Then we proceeded to shred the plastic using the plastic shredder. This part was fun, I may just be weird but there is something mesmerizing and oddly satisfying about watching the plastic being shredded. We also made sure to collect the mico-plastics that fell out of the bin and stick into our bag.

Part 3: Frisbee experimentation

Now that we had gathered our materials, we decided to begin the process of testing out the frisbee. We debated on making a frisbee mold, but the purpose of our product was making something that a child could also repeat at home. We decided to use the pans that we found in the makerspace. We found a medium size pan and a small size pan that we used for all of our experiments.

Trial #1

After we heated the oven and greased up the pan we spread the plastic shreds all over to fill the pan, but not excessively. Then we waxed the outside of the smaller pan and placed it on top to press down the plastic and give it more curvature. But we added way too much plastic into this round and did not press enough pressure on it so it ended up being very clunky and heavy.

Trial #2

In our second trial, we attempted to use plastic bags in order to correct the weight from the previous trial. We mixed plastic bags and plastic shreds together and placed them into the greased up- medium-sized pan and placed it into the oven at 180 degrees Celcius. The result was a complete and utter failure because we realized that plastic bags were too think to be left in the oven at a high temperature for so long.

After this little test, we went back to our original material of shredded plastic which did not include bags. We ran the same exact procedure as the first trial by waxing the medium pan and placing the shreds inside of it and placed it into the oven. This time we left the small-sized pan inside of the oven longer than the first one to make a larger indent into the disc. It actually ended up working out very well after we took it out of the oven and pressed it. The only problem was that the bottom was a tad burnt because we needed to adjust the time since it was a much smaller portion of plastic. But the size was just right, it looked much easier for a child to grasp and play with.

Trial #3

On our third test, we went back to the larger mid-sized pan because we were looking for more curvature than the last couple of tests. We ended up creating a much heavier model than our last products because we had filled up the side of the pans all the way so that there would be a lot more grasp room to hold the frisbee. Basically just extending the curvature to give it more of a frisbee shape and feel. It just ended up making it heavier.

Trial #4

Our last trial ended up having the best weight and design. The size is still a tad too big for children, but luckily when we did user testing it turned out being a decent shape.

We then polished all of the discs and made a sticker design with our logo on them. We really took on the spirit of creating a product, especially after we did user testing on children. It makes the finished product come together even more concise because you can prove that it works. We created our design and used the vinyl cutter to cut our stickers out. Here are the children who were kind enough to throw a frisbee around the cafeteria with me!

The best part about making these frisbees was when we got to test them out in the hallway after they cooled down. This was a crucial aspect of our project that made us consider many different factors in the process. Weight was the hardest to achieve, balancing and evenly distributing the plastic to all sides was difficult to achieve. That is also why our frisbee looks wonkier on some sides. Something to consider moving forward would definitely be to make a mold. Even though it is harder and does make it a little harder to follow along, it cuts downtime and resources that one would be experimenting with in the first place.

We have also created a zine for children ages 7-12 who can read with fun facts and a step by step tutorial on how they can make a frisbee at home. The only thing they wouldn’t have is a shredder, so we just said that one can cut the plastic up into small pieces and place them compactly into the pan. A zine is also an easy tool for the Shanghai market because children and parents are enforcing the education of English as well as sustainability throughout the city. The next step in our project would have been to host a workshop and invite children after sending them the link to our zine.

I think this project sheds light on the issues of consumption and consumerism. It also targets kids, which are becoming more and more aware of the environment around them as well as the catastrophic issues that they are dealing with growing up. It also brings attention to the misconception that 100% recycling is hard or unattainable to do at home. More than anything that Eva and I wanted to achieve was to begin a dialogue about making something that kids can do and be more aware of when they consume or when they buy toys to also make them question whether they are consuming in a sustainable manner. Frisbee was the medium we used because it is something that I grew up with and I loved playing in the park out in the open, but I also think it brings attention to the outdoors and mother nature.

I want to thank Marcela Godoy, Eva Solo, our Re-made in China class, and Emma and Ally (the 2 little girls who tested out our frisbees) for all of the guidance, feedback, and support throughout this project. I really enjoyed making it and also the process of understanding my material, which was #2 and #4 plastic, really well. I became an expert in melting and molding plastic as well as polishing it to give it any look. I am satiated with the finished products that we have made, but if we had more time and planned it out more efficiently, we could have made a mold with our logo and we would not have wasted materials on the sticker.

Thanks again for everything, Marcela! Twas a sensational semester learning and diving deeper into a world of trash.

Leave a Reply