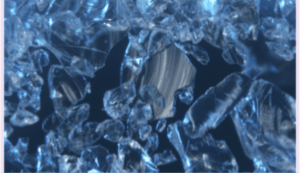

Fig. 1. Particles of Fused Quartz

Fused quartz is a modern transparent soil surrogate, used to represent the geotechnical properties of sand. Fused quartz and fused silica are non-crystalline forms of silicon dioxide. High purity fused quartz is manufactured by melting naturally occurring crystal- line silica at temperatures in the range of 2,000 C. Crystalline silica (silicon dioxide, SiO2) is found in siliceous/quartzite sand and rock. The melting process is conducted in a vacuum to pre- vent bubble formation, which helps enhance transparency. Crushed fused quartz is most often a byproduct of industrial processes for the manufacture of semiconductors, solar cells, telescope and microscope lenses, telecommunication equipment, and glass chemical containers. Several suppliers manufacture the material to a wide range of different particle size specifications. The material can be matched with several pore fluids including (1) sucrose solution, (2) a blend of mineral oils similar to baby oil, and (3) sodium thiosulfate-treated sodium-iodide (STSI) as Shown in Fig. 1

The ability to model sand using two immiscible pore fluids permits modeling multiphase flow problems, coupled flow-deformation problems, as well as vadose area environmental hazard problems. Moreover, the fluids employed are inert and non-toxic, which facilitate their use in research and educational settings. The resulting model has exceptional transparency in which an ophthalmic chart is seen through a 5-cm-thick layer of fused quartz saturated with a mineral oil solution on top and a sucrose solution at the bottom (Fig. 2).

Fig. 2. Ophthalmic chart is seen through a 5-cm-thick layer of fused quartz

Fused quartz possesses chemical composition and shape characteristics similar to those of natural silicate sand. The static and dynamic properties of fused quartz are similar to those of angular natural sand (Fig. 2, 3). Fused quartz has been employed to investigate soil–geosynthetic interaction during pullout unsaturated flow, and penetration mechanics.

Primary References

- Omidvar, M., M. Iskander, and S. Bless (2016). Soil-projectile interactions during low velocity penetration. International Journal of Impact Engineering, doi: 10.1016/j.ijimpeng.2016.02.015, Elsevier [link]

- Carvalho, T., E. Suexcun-Florez, M. Omidvar, and M. Iskander (2015). A non viscous water-based pore fluid for modeling with transparent soils. Geotechnical Testing Journal, Vol. 38, No. 5, doi: 10.1520/GTJ20140278, ASTM [link]

- Guzman, I., M. Iskander, S. Bless (2015). Observations of projectile penetration into a transparent soil. Mechanics research Communications, Vol. 70, Dec., pp. 4-11, doi:10.116.j.mechrescom.2015.08.008, Elsevier [link]

- Omidvar, M., J. Doreau Malioche, Z. Chen, M. Iskander, and S. Bless (2015). Visualizing kinematics of dynamic penetration in granular media using transparent soils. Geotechnical Testing Journal. Vol. 38, No. 5, doi: 10.1520/GTJ20140206, ASTM [link]

- Omidvar, M., J. Doreau Malioche, S. Bless and M. Iskander (2015). Phenomenology of rapid projectile penetration into granular soils. International Journal of Impact Engineering, Vol. 85, No. 11, pp. 146-160, doi: 10.1016/j.ijimpeng.2015.06.002, Elsevier [link]

References by Others

- Ezzein, F. M. and Bathurst, R. J., 2011, “A Transparent Sand for Geotechnical Laboratory Modeling,” Geotechnical Testing Journal, Vol. 34, No. 6, pp. 1–12 [link]

- Kong, G., Cao, Z., Zhou, H., Wang, Z. T., Yang, G. and Li, H., 2016, “Shear Modulus and Damping Ratios of Transparent Soil Manufactured by Fused Quartz”, Materials Letters, Vol. 182, pp. 257-259 [link]