Last week unfortunately I did not have a chance to actually try out the machine, I simply put my CAD on the software and edited a bit. What I was testing out was a component for my final project that I want to make on the lathe and the 4-axis.

It used to be the middle connection part of the axe that I made before, and now I want to put these engravings on it and possibly do some powder inlay with wood/metal.

So this week I wanted to test how I can do engraving on the 4-axis and if can I control the exact position of them along the axis of rotation.

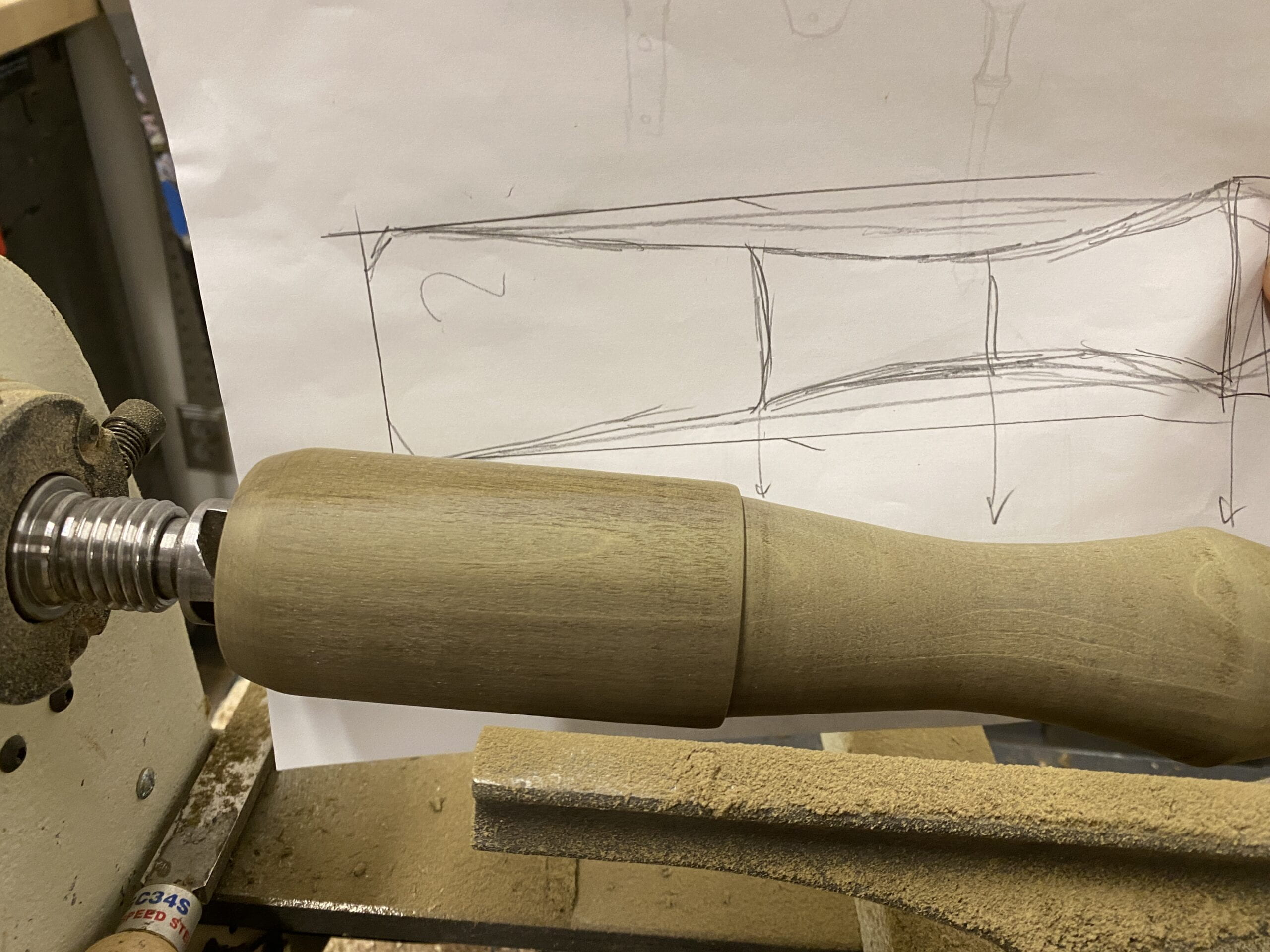

I prepped my material to be as close to my actual piece as possible on the lathe, and put it ont the 4-axis,

I also cut my model in half since it is just a proof of concept.

Unfortunately, someone before me might have reset the y axis while doing the z so the machine was just milling air while the actual material is a mile away.