For this week’s enclosure assignment, I was planning to make a cardboard enclosure of all my previous projects, which also works as a storage box and a presentation tray.

I originally wanted to make this out of laser-cut pieces of acrylic, but there were two problems: 1, they will scratch after several usages, and 2, there wasn’t a piece of material large enough for me and I didn’t feel like purchasing materials just yet.

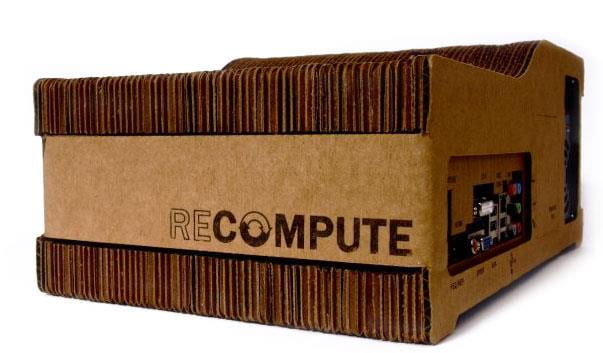

So, I looked around the shop, and someone dropped off a huge number of cardboard boxes on the shelf, and that becomes my final material of choice. My inspiration comes from this project that we showed in class.

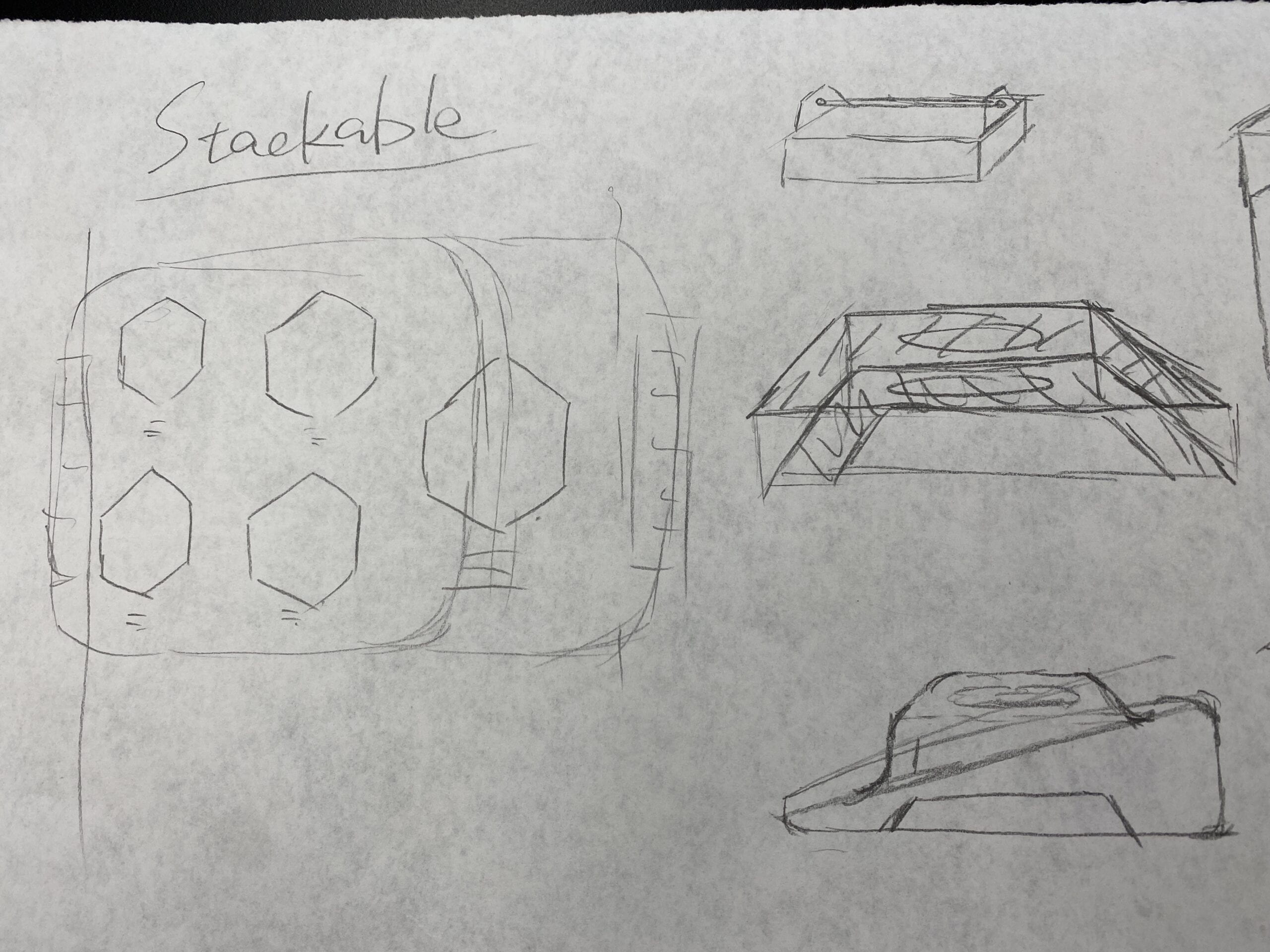

the advantages of cardboard are that they are lightweight, fairly durable, and have easily replaceable parts. My design would also make it stackable, which makes it super satisfying as a storage component.

However, I realized mid-testing that this idea is wayyyyyyy too ambitious to finish in a week, it might be possible if I had nothing else to do. So, I quickly shrunk it to just testing one tray for one of my past projects.

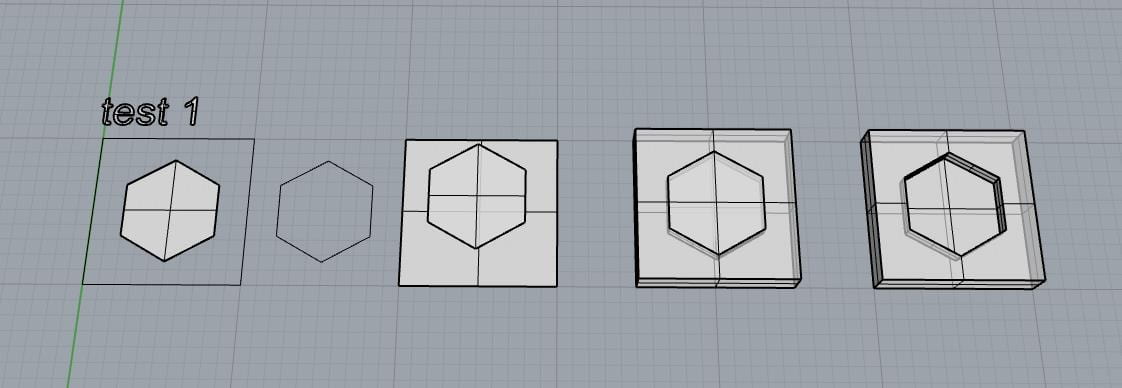

So I began testing.

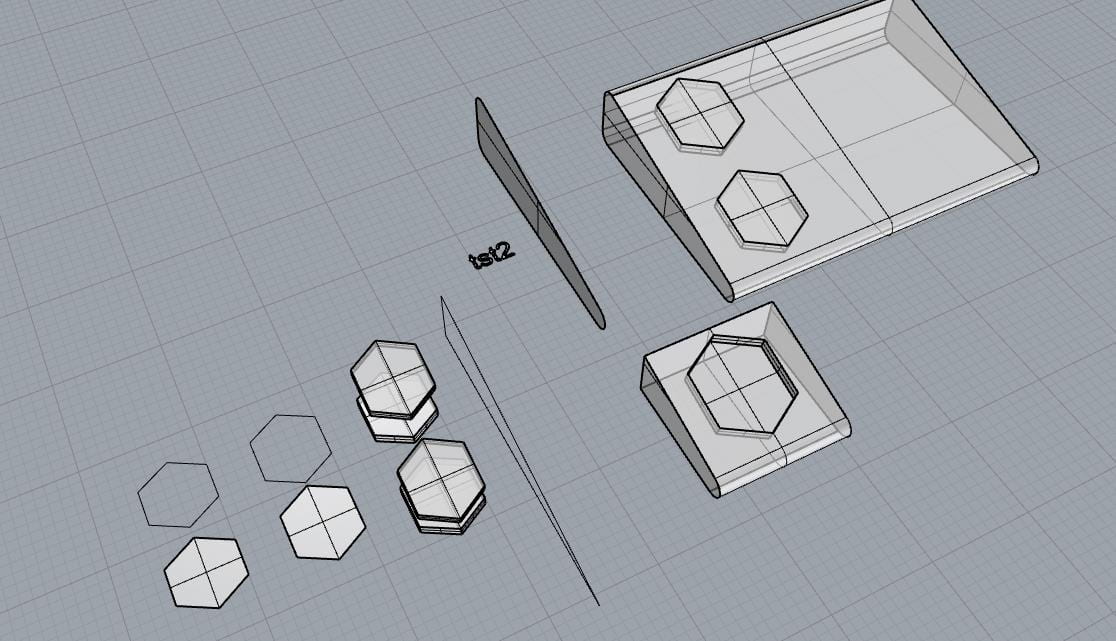

This is my first version. I made a box and indented it with the shape of one of my pieces of patterned ply, But I did not offset it, thinking that cardboard might be flexible enough for me to just squeeze my piece in without much trouble. Of course I was wrong.

the method I used to convert it into laser-cutable pieces is through the Fusion360 slicer. But I didn’t realize that the jagged edge in here is actually inner-tangent to the edge of my actual piece. In human language, it means it is smaller than I thought. So naturally the piece didn’t fit. By the way, I made a quick and dirty right-angle jig using the right-angle clamps for assembling the pieces.

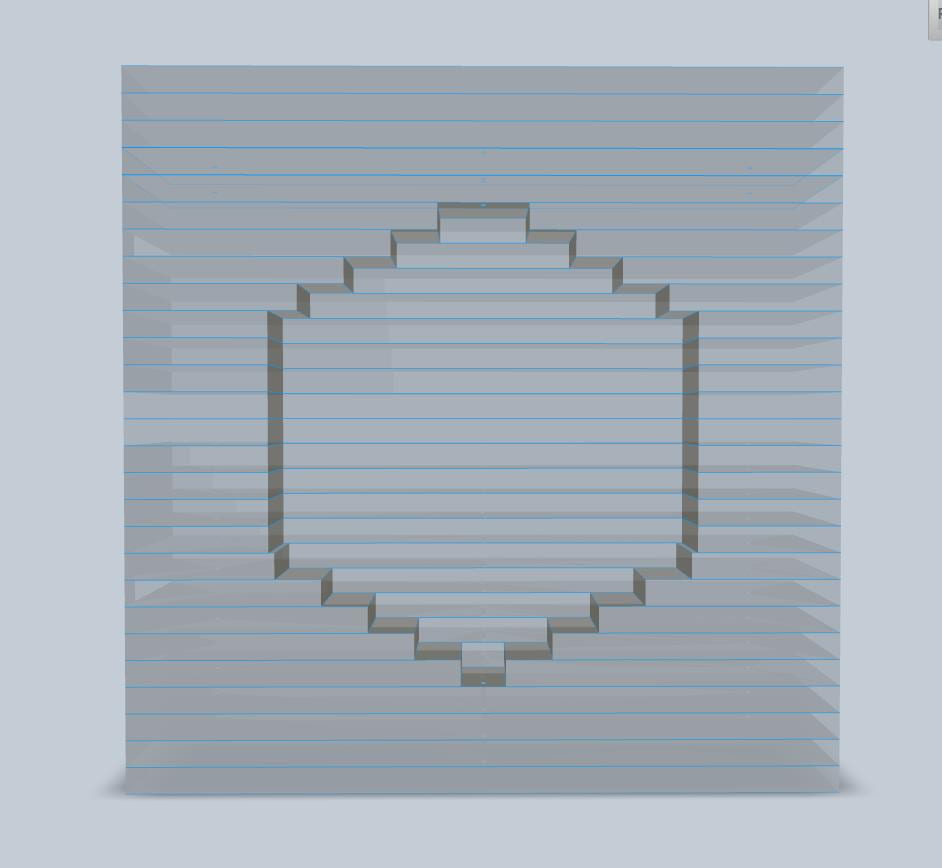

So I moved onto test 2. I slightly increased the height of the hole, and also made the shape that I wanted the final tray to look like.

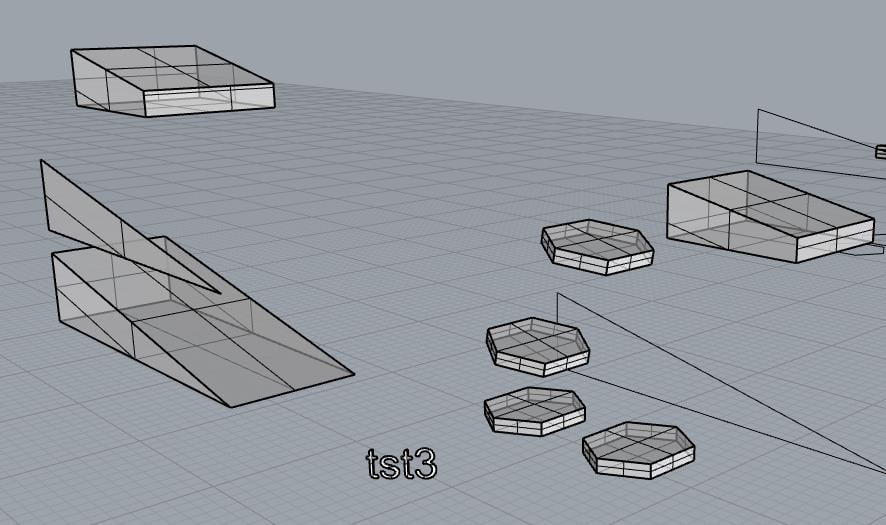

but then I found out fusion 360 slicer didn’t really like rounded edges, so I made a more straight-edged design in test 3.

Also I rotated the piece by 90 degrees since I was noticing some springiness in the assembled cardboard, thinking that would make it easier to fit the tip of my piece. And nope, I was wrong again. I realized that what was not fitting was actually the flat edges, and I ultimately had to offset the shape to make it larger.

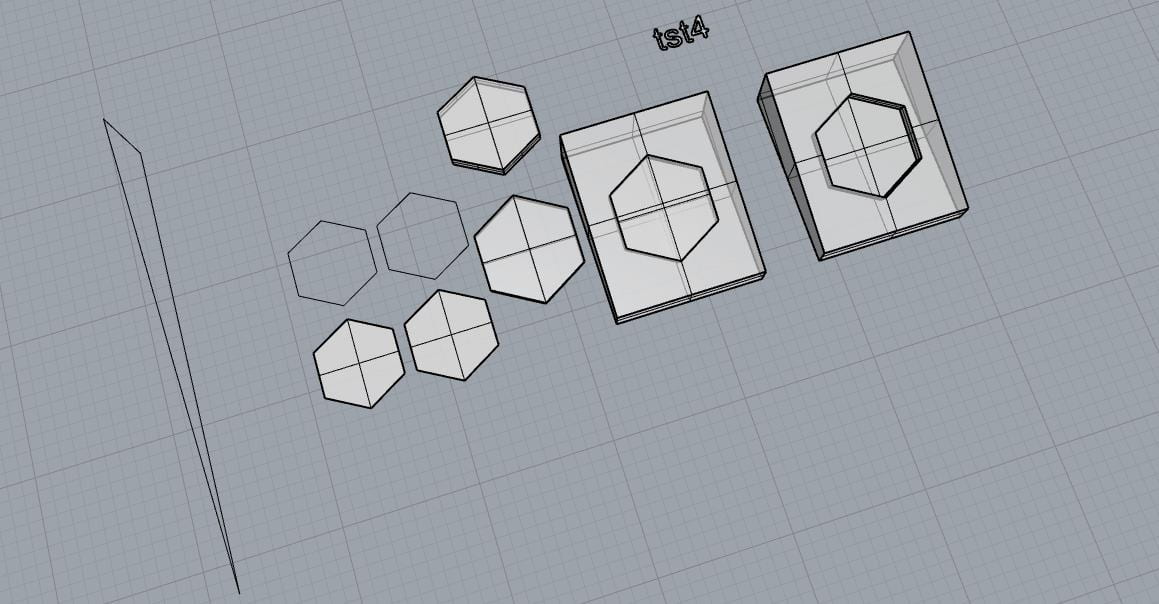

So I did that in test 4, and at this point I was running out of time to even do one tray, so I decided to just fit one piece.

Test 4 is the most effective.

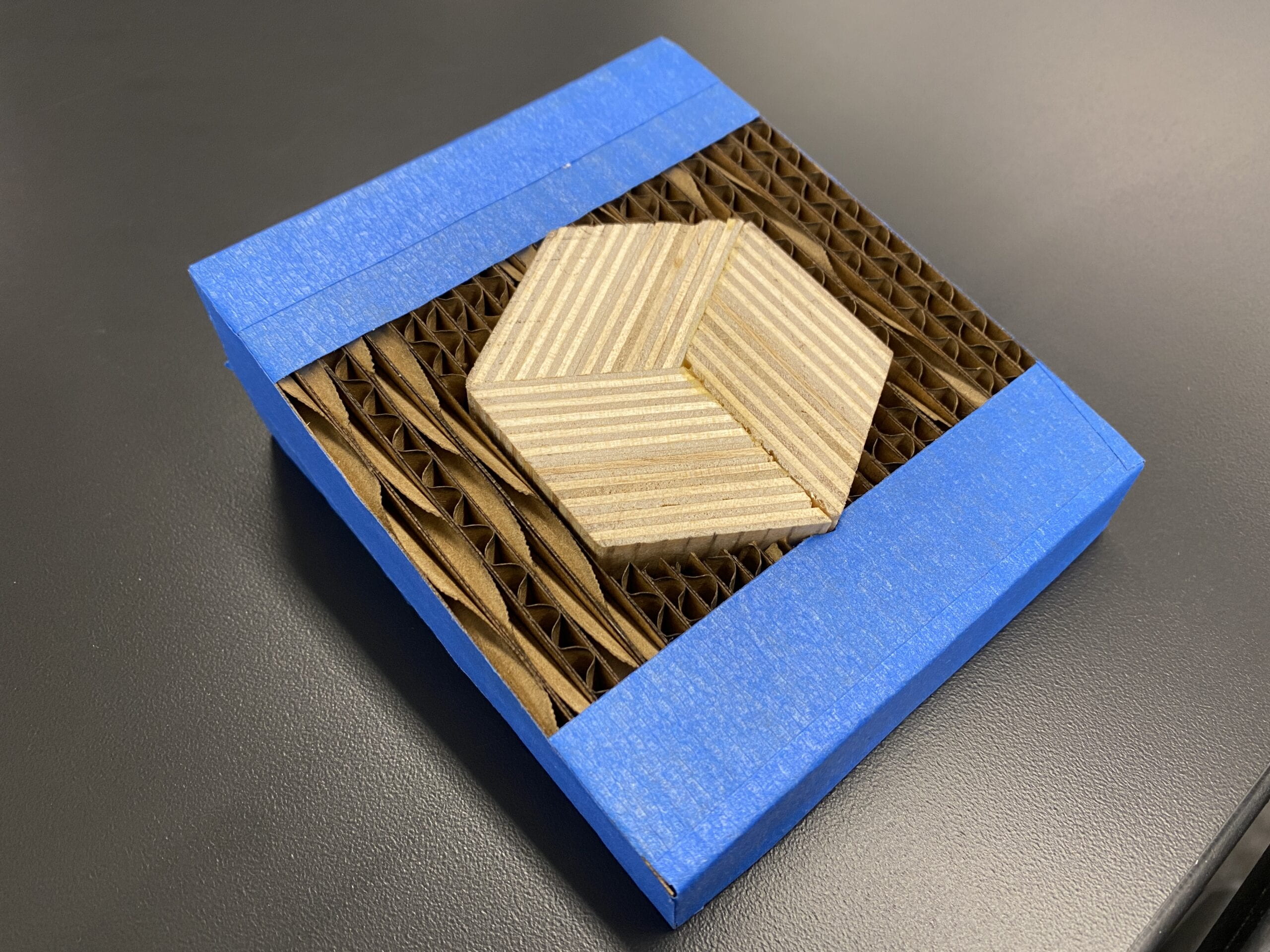

So I cleaned them up, blue taped them, and here is the final product.

Final verdict: