I continued with my testing for the runes on storm breaker, I was able to finish what I couldn’t cut from last time and got the result below:

I got this result in about 50 mins, and I was pretty impressed with the surface finish.

But I didn’t really like how shallow those runes are (as it might not grab onto the infill very well especially since the grooves are not straight but have a slope). I later changed the depth on my model, but I found out that it did not matter because lots of the runes are still too thin for 8mm ball mill, and using 16mm flat end mill will just take too long (4hrs plus). So I’m thinking about a redesign.

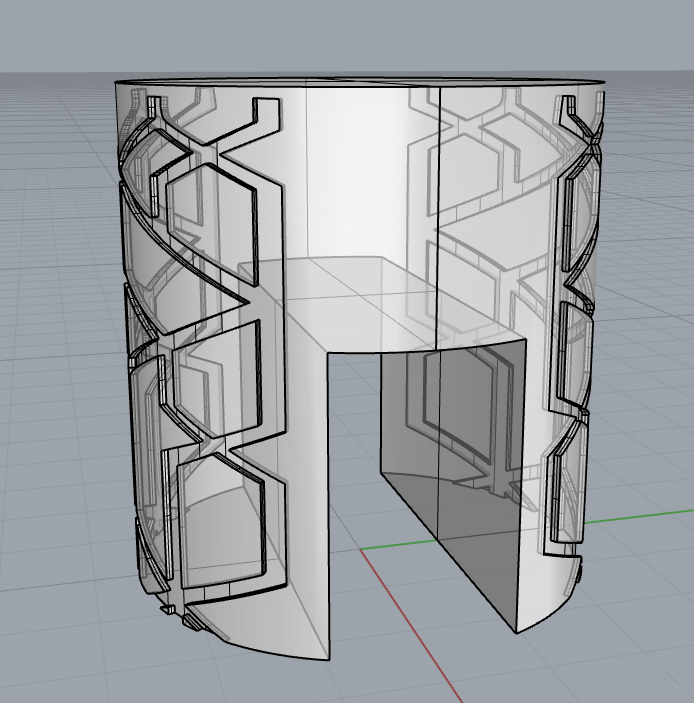

this is the redesigned part. without the irregularity at least I was able to control exactly how big the grooves are. I proceeded to cut it on the 4 axis.

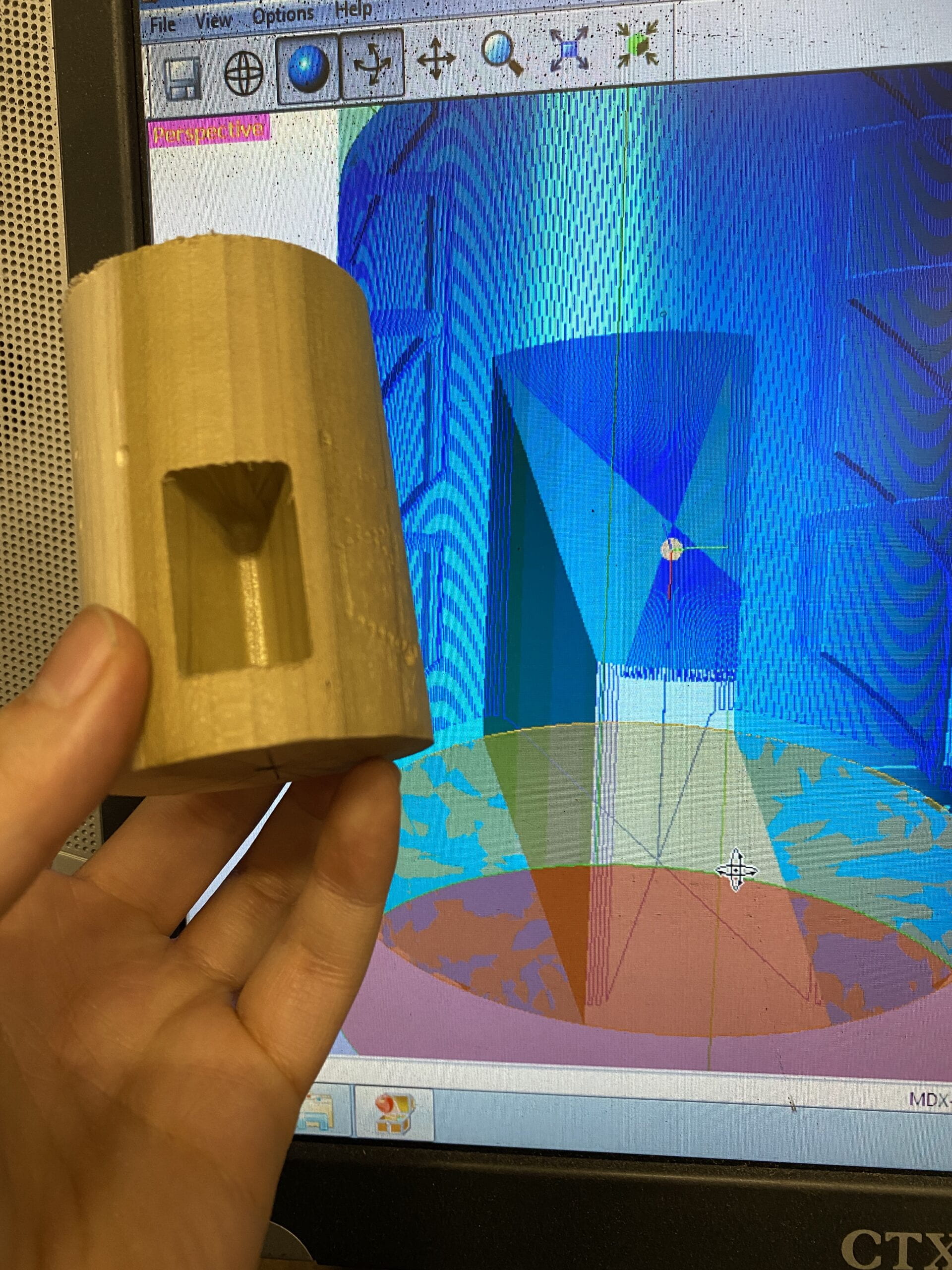

somehow the mostly uniform grooves ended up not even on the cut in the end.

somehow the mostly uniform grooves ended up not even on the cut in the end.

also the machine did not successfully cut through the notch on the bottom, instead it cut a v-shape.

also the machine did not successfully cut through the notch on the bottom, instead it cut a v-shape.

I consulted phil, who said that it might be because of two things: one is that my model might not have been a closed shape, and also because I did not run a finishing pass. I plan to fix both things in my next test. Which I wasn’t able to do because someone changed the y axis again on the machine which was pretty annoying.

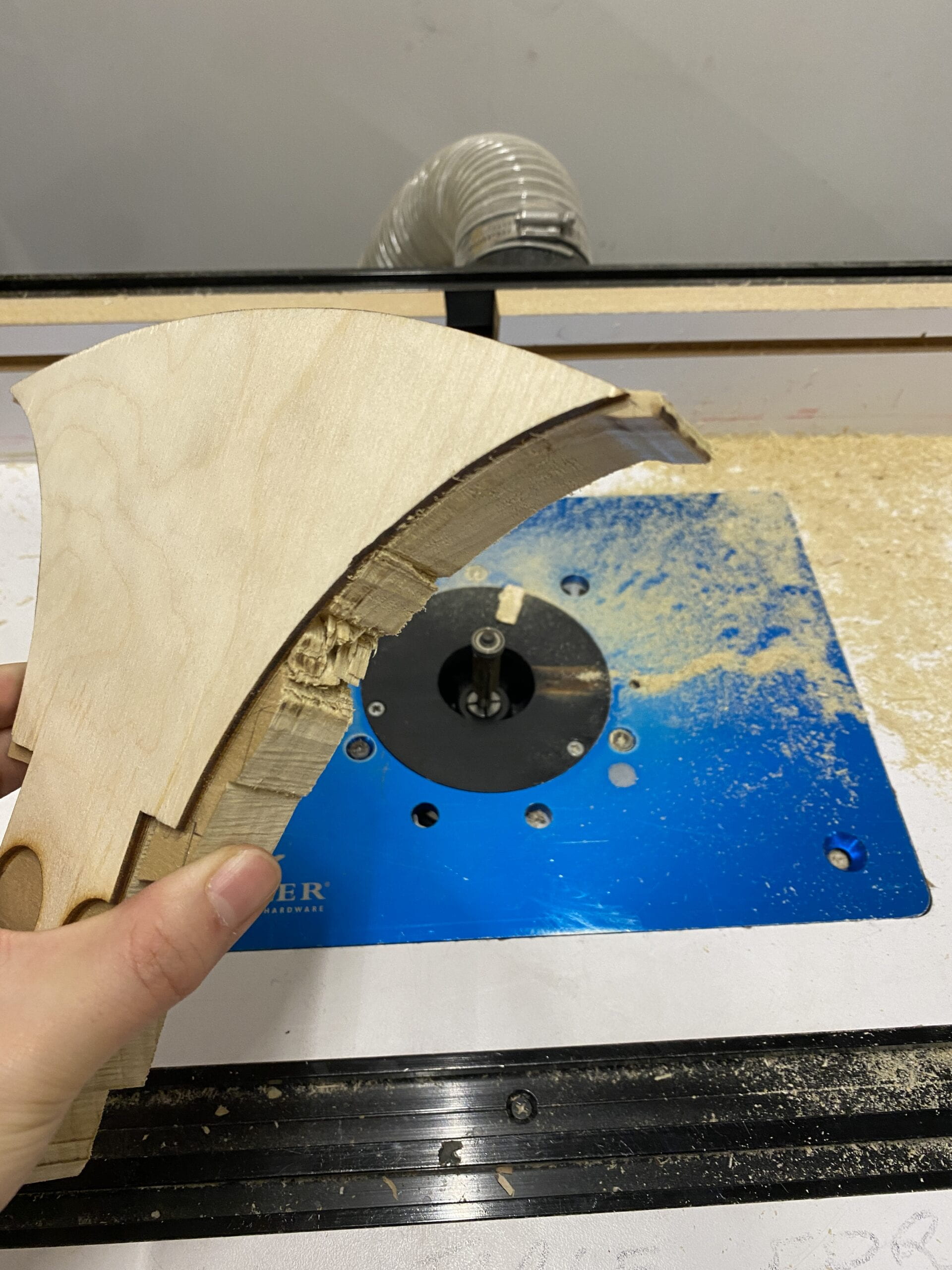

Also, I was able to cut and wax both the ax part and the hammer head with the band saw, router and lathe.

p.s. router table was not really the tool for the job, or maybe the bit was just too dull.