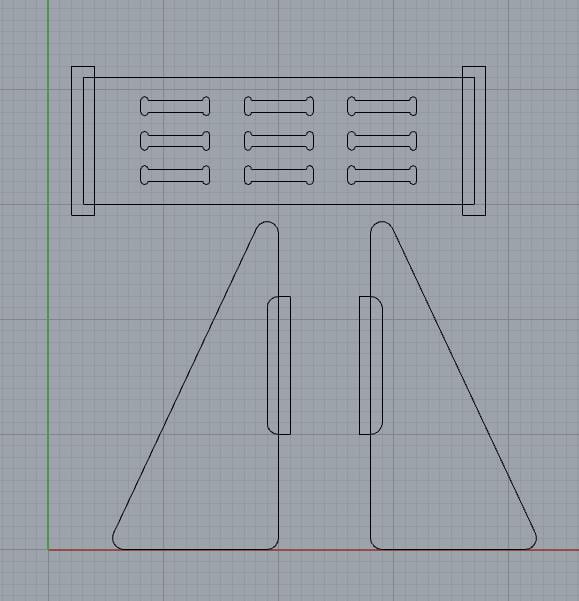

Continuing with my previous design, I made rabbet joints as the connections between the boards. I made the pocket outline slightly larger so the CNC could cut all the way. I slightly modified the shape of the tray in the middle and the positions of the magnet holes.

There was one accident on the CNC. When I started cutting on the machine, I accidentally selected the .dxf file rather than the .nc file. And this resulted in (according to Ben) the machine cutting the last file it cut rather than my file, which made the router somehow plunge down super deep into the board, and start to cut all the material, including quite a few mm of the spoil board. I hit the e-stop before it cut further but it already went for about 3 inches. luckily, the bit didn’t break, and no one was injured. Unfortunately, I was too shocked at the time to take a photo of the situation, so you will have to take my words for it.

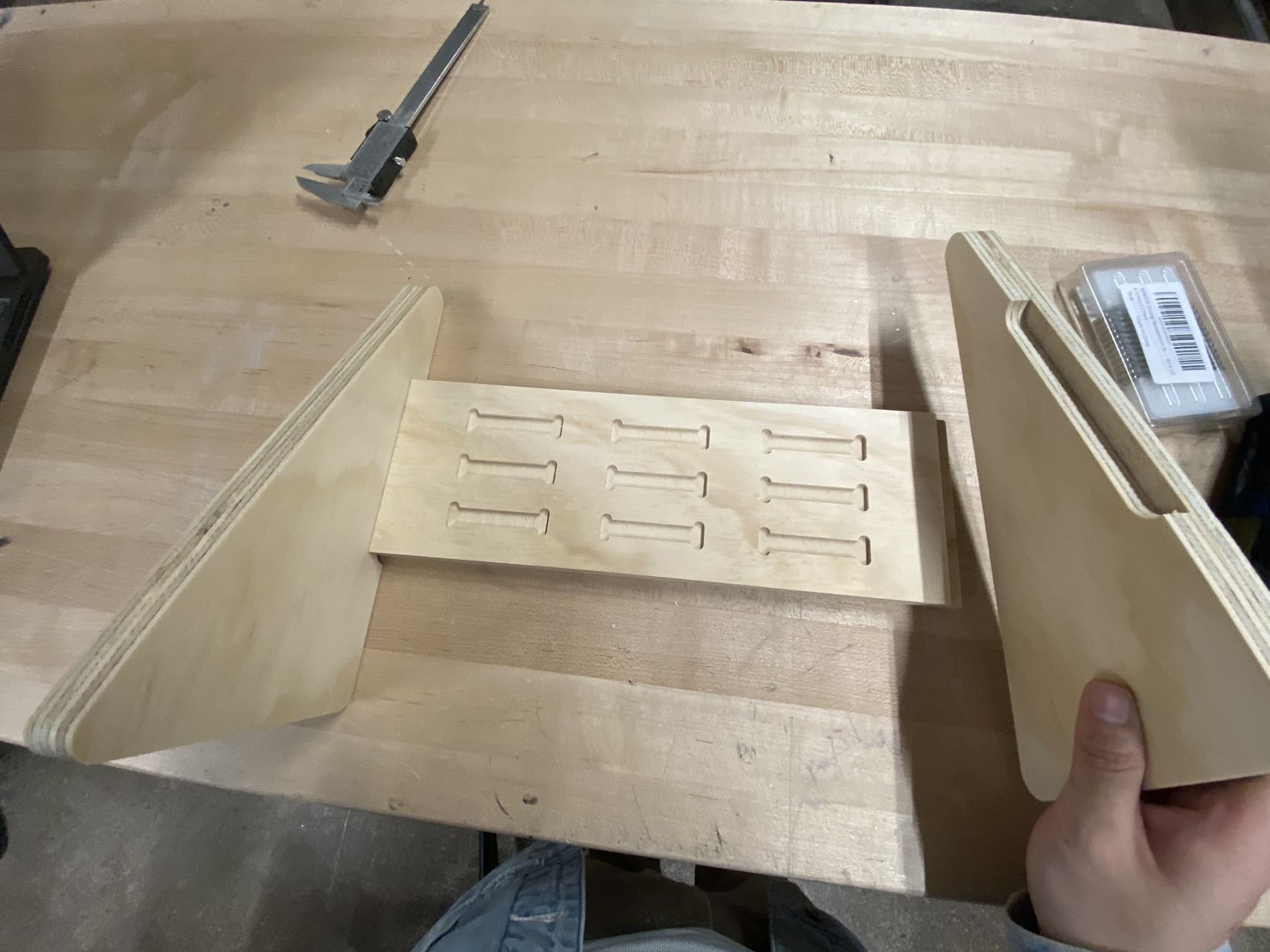

when I finished the first cut, I realized that the left and right pieces should be mirrored rather than simply the same piece rotated 180. so the resulted in this situation above. I quickly cut another version, (which is when the accident happened), and went ahead and glued them together.

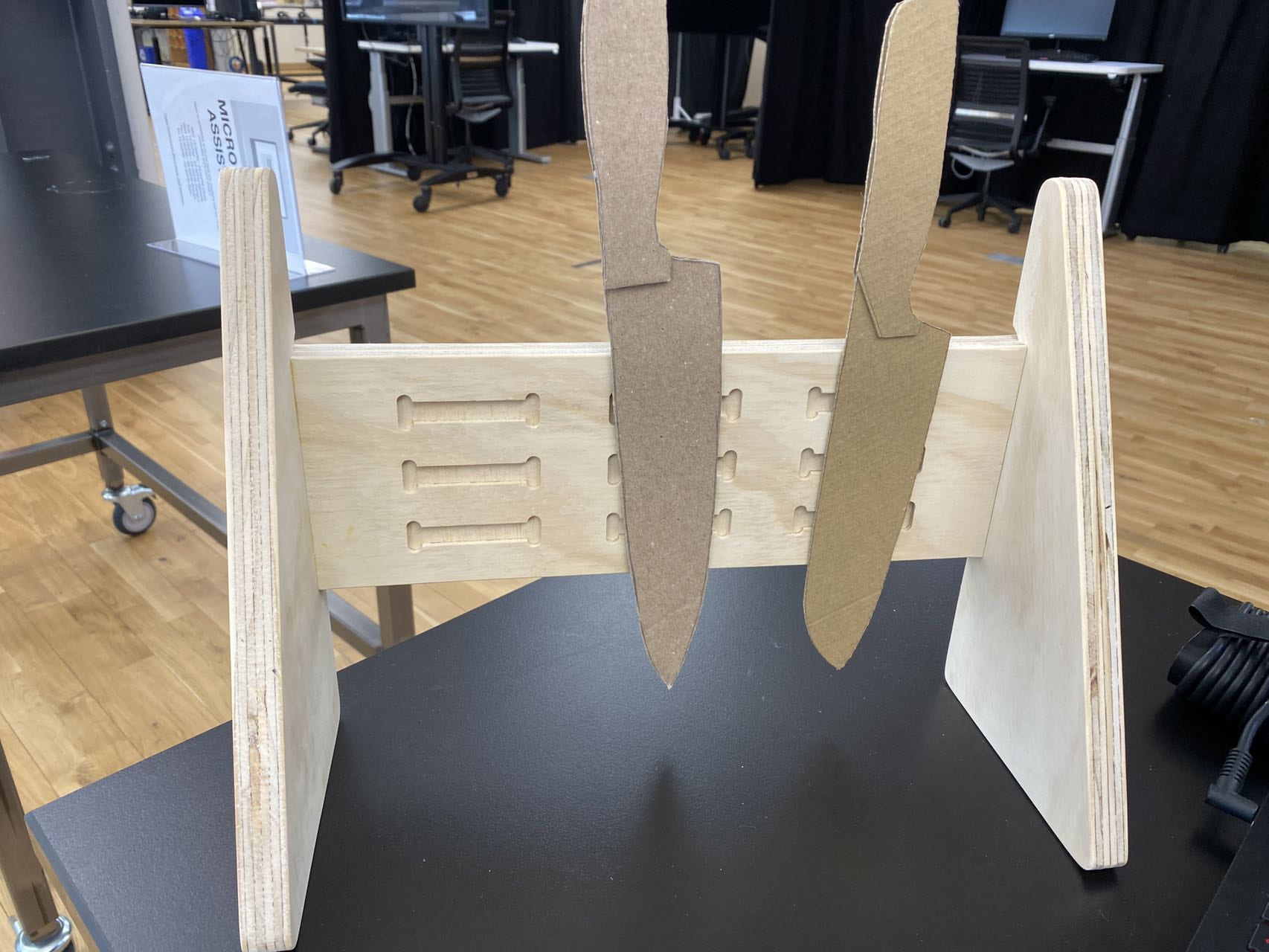

and here is the final product with my cardboard replicas of my own kitchen knifes.