Design:

For this one, I downloaded a wrench icon of a small wrench and decided to test out how to use the Othermill and familiarize myself with the workflow and settings.

Process:

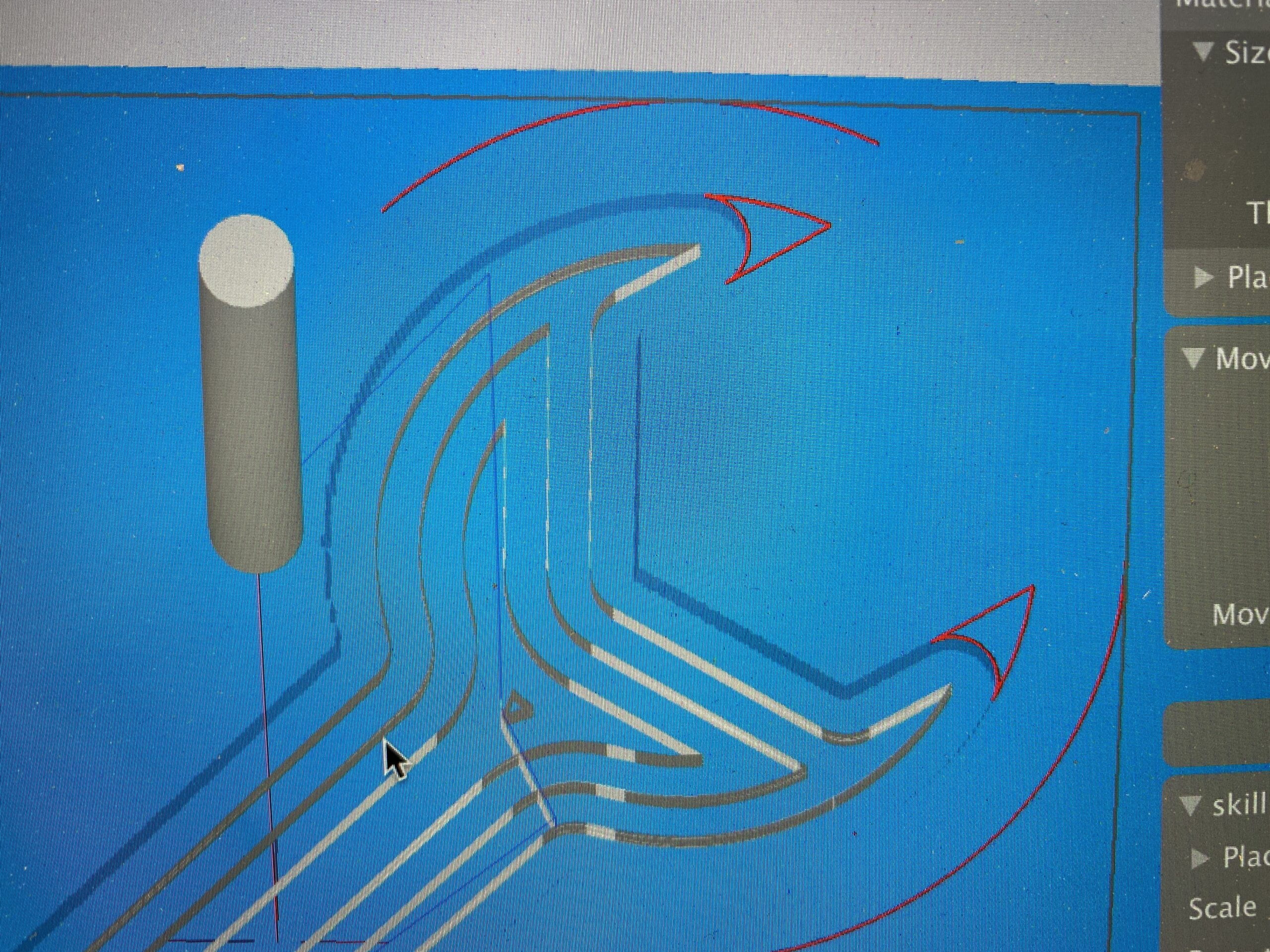

I put the file in Bantam tools, and in advanced settings, I reversed the whole cut since I want the engraving to be inside and couldn’t figure out now to do it in the correct orientation. I tried reversing the image in Illustrator but everything ends up looking pretty weird. So I kept this setting.

Also, since the tips of the wrenches are really small, I could have milled the entire thing again with the 1/16” bit (and that would also make the bottom of the engraving look more smooth), but it was mostly milling air since most of the material was removed, so I didn’t really bother to.

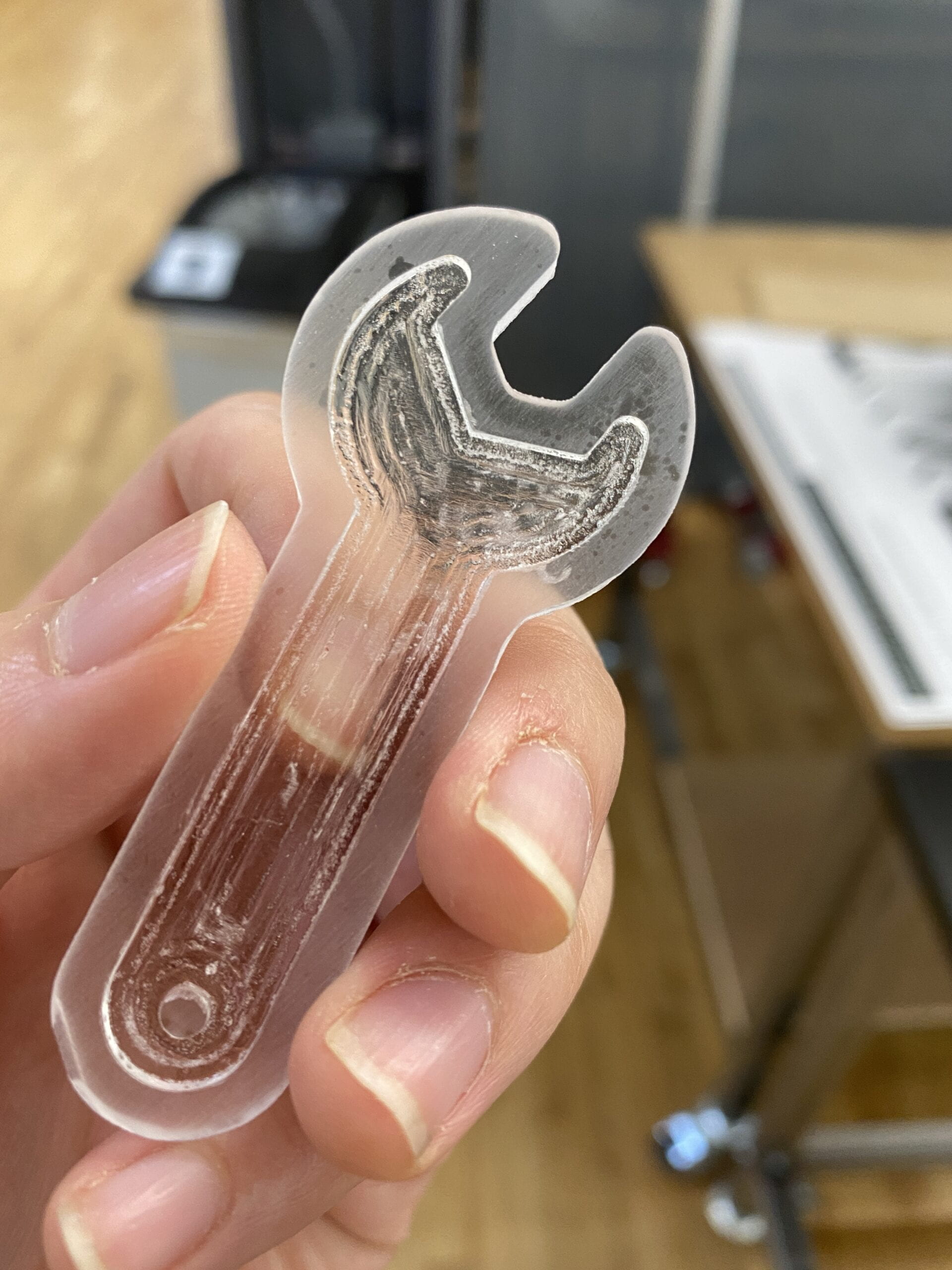

Here is the piece fresh out of the mill, the step-in of the 1/8” bit was pretty rough, hence the lines and circles in the engraving.

I tried hand sanding the surface and edges and also used the Dremel to sand the inside, not really too satisfactory, maybe putting finish on it would make it easier on the eyes, and also Angelo suggested I do vapor smoothing so I might give that a try later.

Thoughts:

Question:

- What are the settings of FEM acrylic? Most importantly feed rate & spindle speed, are there other things to note in the settings? What properties of the material determine the settings?

- 2 flute VS 3 flute difference? The Amazonas link given in the lecture was not exactly 1/8”??

- Better ways of securing the piece on the bed aside from going nuts on the tape? Clamping? Adding one more layer of bed (wood) and putting holes for small screw clamps? Is that only applicable for big CNC machines?

- What is the common practice of securing lightly warped wood as good as we can? Or we just don’t use them?

- Why does the CNC still cut the bed when it knows exactly where it was???

- Rhino? Please?’

- What does isopropyl alcohol do?