Drawing Machines

Components:

1 * 42STH33-0404AC stepper motor

1 * SN754410NE ic chip

1 * power jack

1 * 12 VDC power supply

1 * Arduino kit and its contents

2 * Laser-cut short arms

2 * Laser-cut long arms

1* Laser-cut motor holder

2 * 3D printed motor coupling

5 * Paper Fasteners

1 * Pen that fits the laser-cut mechanisms

Paper

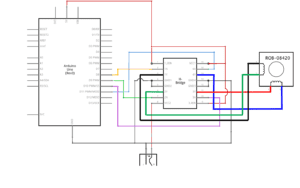

Step 1: Build the circuit

In the first step, I connected a stepper motor to our Arduino through an H-Bridge. An H bridge is an electronic circuit that switches the polarity of a voltage applied to a load and allows DC motors to run forwards or backwards.

First of all, I successfully and quickly linked the circuit according to the circuit diagram. I connected Arduino to my computer and uploaded the stepper_one Revolution code. Then I plugged the USB into the protective socket. I was surprised that my stepper motor didn’t rotate. I suspected my circuit connection was wrong. So I checked my circuit over and over again, but there seemed to be no problem. Later, I found out that I didn’t connect to the power supply. The USB interface powered Arduino and we needed an extra power supply to power the stepper motor, which I overlooked, leading to my failure. After connecting the stepper motor to the power supply, I finally succeeded in my first step.

Step 2: Control rotation with a potentiometer

Because I wasted too much time in the first step, I was a little flustered in the second step. After I connected the three feet of potentiometer to the positive and negative poles of the circuit and Arduino’s A0, I began to deal with the code. First I change STEPS 100 into 200 because the 42STH33-0404AC Stepper Motor is a 200 step motor based on the instruction. Then I wrote val= map (val, 0, 1023, 0, 200); below void loop() to match the movement of the knob with the rotation of the motor. It worked but I can’t control the drawing machines using the potentiometer. So I added a parameter pot to measured variables. Therefore, it worked successfully.

CODE

#include <Stepper.h>

// change this to the number of steps on your motor

#define STEPS 200

// create an instance of the stepper class, specifying

// the number of steps of the motor and the pins it’s

// attached to

Stepper stepper(STEPS, 8, 9, 10, 11);

// the previous reading from the analog input

int previous = 0;

int pot = A0;

void setup() {

// set the speed of the motor to 30 RPMs

Serial.begin(9600);

pinMode(pot,INPUT);

stepper.setSpeed(30);

}

void loop() {

// get the sensor value

int val = analogRead(pot);

val= map(val,0,1023,0,200);

// move a number of steps equal to the change in the

// sensor reading

stepper.step(val – previous);

// remember the previous value of the sensor

previous = val;

}

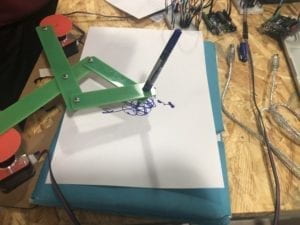

Step 3: Build a Drawing Machine!

In the third step, I paired up with a partner and created a drawing machine, using laser-cut arms, a laser-cut motor holder, a 3D printed motor coupling and paper fasteners. The assembly process is relatively smooth, although the brush cannot be fixed firmly. Hard as the drawing machine is to use, we have a great sense of achievement.

Question 1:

What kind of machines would you be interested in building?Add a reflection about the use of actuators, the digital manipulation of art, and the creative process to your blog post.

I want to build a machine that can automatically classify garbage. In my life, I find that the reason why people don’t classify garbage is not that they don’t have this awareness, but that they don’t know the specific rules of garbage classification. If there is such a machine that can help to classify, human production will be more environmentally friendly.

An actuator, as a “mover”, requires a control signal and a source of energy. For environmental reasons, I hope my machine can be powered by solar energy. In this way, the solar energy is converted into electricity, and then into mechanical energy, and then the machine can run. People put garbage in and press a startup button to enable the machine to perform tasks and classify garbage by scanning.

I think the digital manipulation of art has brought infinite possibilities to both art and technology. Combined with art, electronic technology is more aesthetic; combined with technology, the forms of art are more diverse, and what is conveyed can also have the characteristics of the times. The garbage sorting machine I want to make is not only an advanced technology, but also an art of how human and nature live in harmony. Through science and technology, we try to learn and practice the art of coexistence.

I think the creative process is difficult but exciting. A good idea is like the child of the creator. From its germination to formation, the creator pours his heart and soul into it. And when the creator sees his product being applied, his heart will be filled with happiness. I think that creativity comes from daily life, just like what causes me to create garbage sorting is that I find people in life don’t classify garbage. And then I think about the reasons and germinate ideas. So I think we should observe carefully in our life, find out the problems, and use our creativity to find solutions.

Question 2:

Choose an art installation mentioned in the reading ART + Science NOW, Stephen Wilson (Kinetics chapter). Post your thoughts about it and make a comparison with the work you did during this recitation. How do you think that the artist selected those specific actuators for his project?

I like the work called Mechanical Mirrors: Wooden Mirror designed by Daniel Rozin. It is a computer-controlled installation recreates digitized video images of viewers, according to ART + Science NOW, Stephen Wilson (Kinetics chapter). I think it perfectly shows what the digital manipulation of art is. While using the technology, this machine has created a picture full of artistic beauty for us.

Similar to the drawing machine I created during recitation, the project called Mechanical Mirrors outputs in the form of visual images. Both of them embody the combination of art and technology. The difference is that our drawing machine inputs information physically (manually adjusting the potentiometer), and this machine monitors the input information through the camera. The actuator used by the designer Daniel Rozin is not limited to physical input. It embodies the automation, flexibility and artistry of the machine.