In this lab, we focused on making robots that use legs to move instead of wheels.

At the beginning, my team and I decided to make a robot that mimicked the movement of a jellyfish. Instead of moving in water, however, we would have it fly around in the air. Our initial thought was to use a helium balloon to pick up the entire wing mechanism. However, we ran through some problems with acquiring a helium balloon. So, we decided to move on to making a purely mechanical mechanism that moved by lifting itself up as demonstrated in the video in the link below:

https://www.nature.com/news/robot-jellyfish-takes-to-the-air-1.14528

After making a few prototypes of the mechanism, we realized that we did not have materials light enough and a motor fast and strong enough to execute the design. So we decided to change paths and design our robot after the mudskipper.

https://www.youtube.com/watch?v=pZb4IUZvgL0

Although they are a fish, they spend a lot of their time on land, and so they have flaps that allow them to move around on land. In order to replicate this, we followed a design that involved carrying the body forward on its legs.

Our first prototype was made completely of cardboard. However, we quickly realized that there were a few problems we had to fix. For one, the axel connections between the legs and the body were not completely straight and thus caused the three points of contacts to move at different rates and different times, prohibiting it from moving forward. The second main problem was that the cardboard connection between the secondary axel and the legs was too soft. As a result, instead of turning, the connection would just bend and fold, stopping the legs from moving forward. The third main issue was the pulley system. We experimented with attaching a rubber band from a motor to the pulley and first saw that there was not enough traction between the cardboard pulley and the rubber band. As a result, the rubber band would not turn the pulley but instead bunch up around the motor.

To fix these three problems we iterated on our previous prototype. To fix the issue of the axel connection not being straight, we simply applied the hot glue and pressed it against the edge of the table (a 90 degree angle) in order to have the glue hold the connection at a right angle. To fix the second issue of the cardboard being too soft, we decided to use a much harder cardboard. However, although the cardboard was firm as a large board, when cut up, the individual parts became rather soft and also bent while we turned the axles to move the legs. To address the third problem, we decided to attach masking tape to the pulley in order to add some friction to the pulley. We also applied some ridges to the tape while folding it into the crevice of the pulley in order to increase traction. However, we found that this did provide enough friction and thus did not reliably turn the pulley.

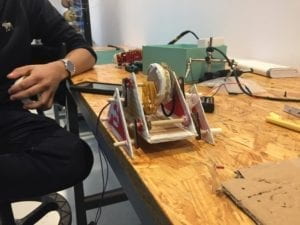

Thus, we had to iterate our design one more time. The third time, we decided to laser cut our connections in order to make sure they would not bend and would be completely sturdy. This worked and provided a strong connection between the body and the secondary axles and the legs. Also, we decided to switch to a plastic tape that had a much higher degree of friction with the rubber band which reliably turned the pulley. After gluing down the motor, we found that this final design worked.

Reflection:

This project involved a lot of prototyping and iteration which taught me about the process of building a robot and how to improve on a project step by step. I enjoyed identifying the problems and figuring out how to improve upon the robot each time.

In regards to improving upon this robot, I would use a strong motor that would be able to turn the pulley faster and also use a smaller pulley which would turn the legs faster potentially allowing the robot to skip along like a jumping frog.