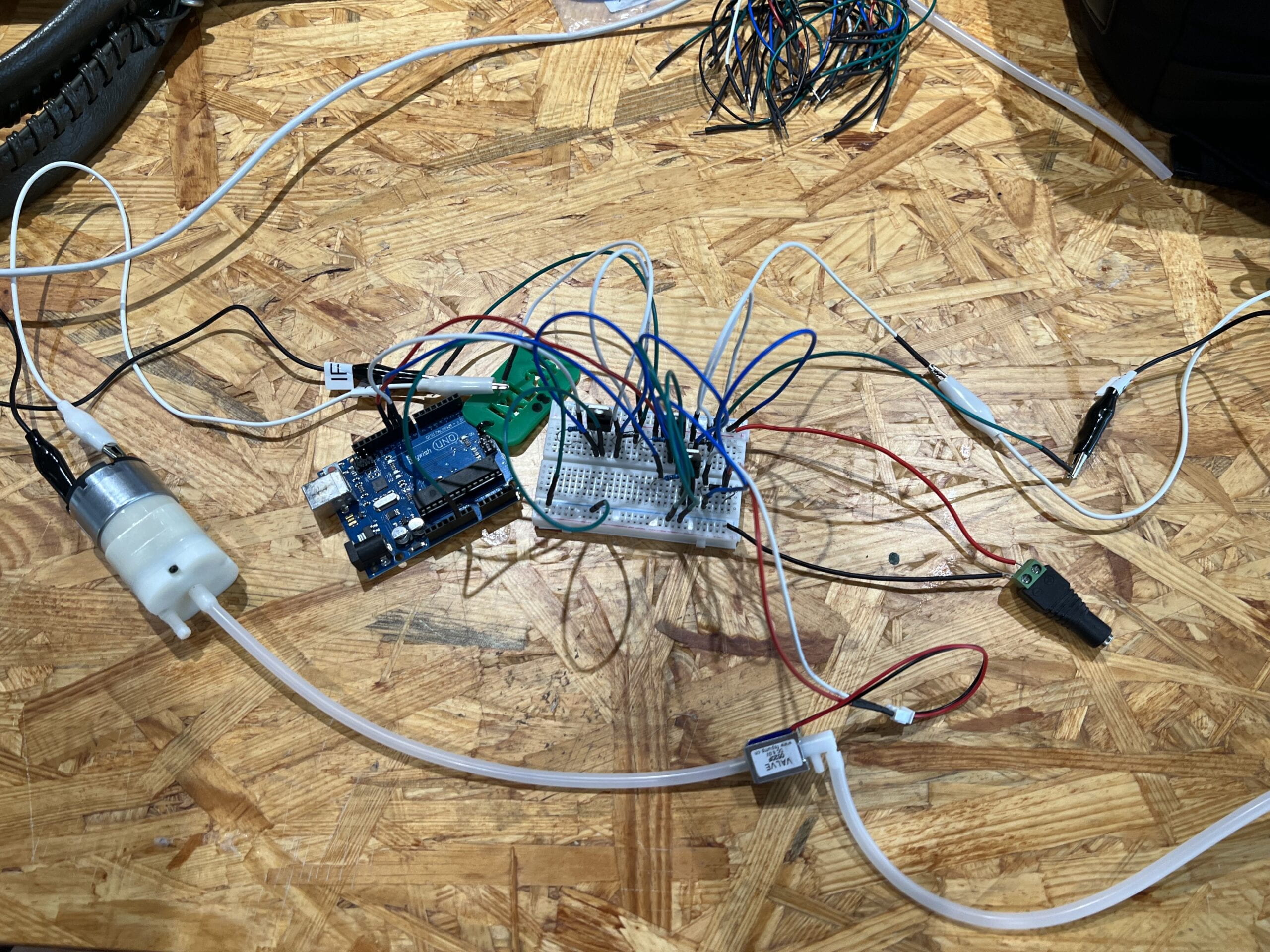

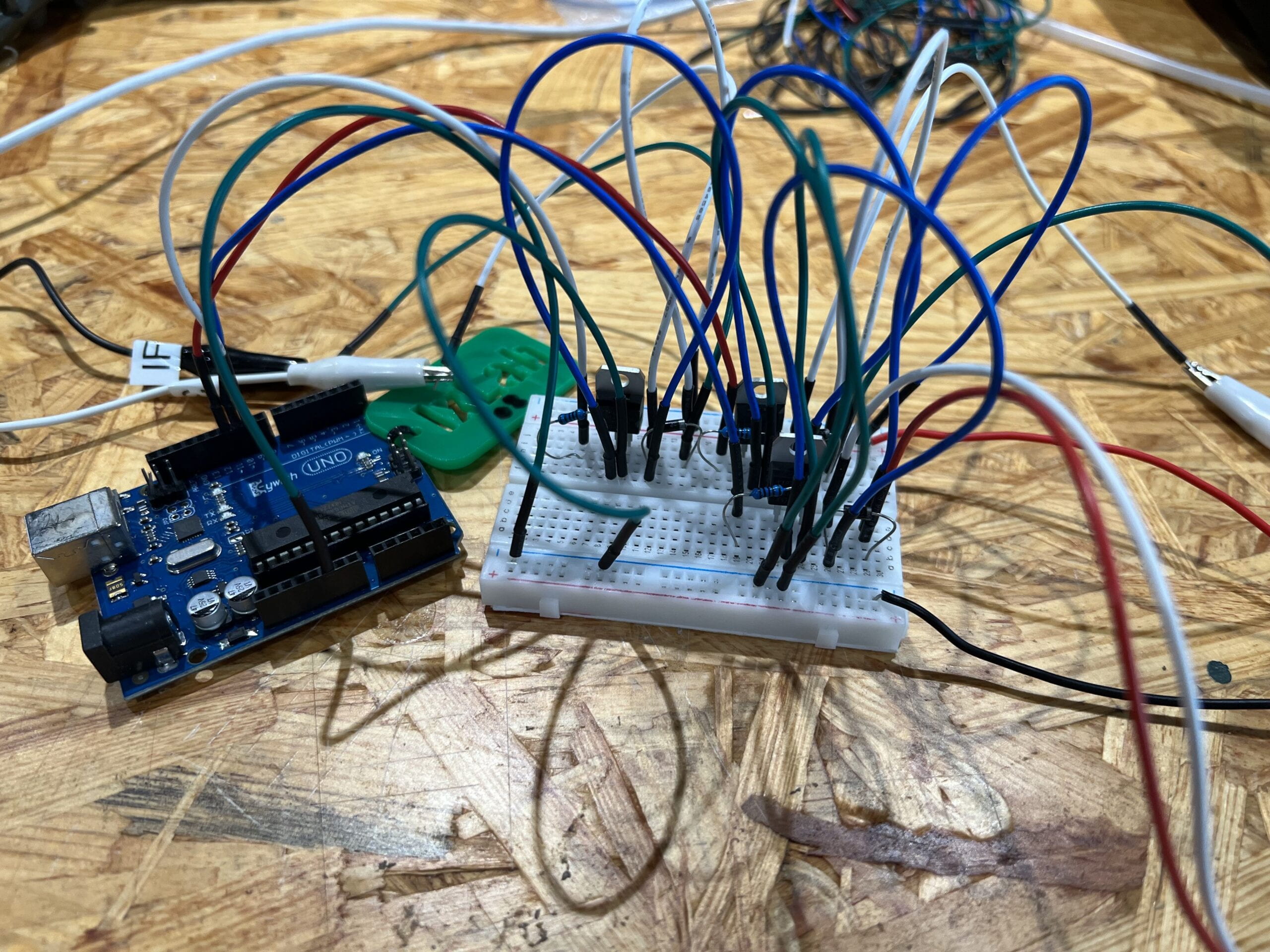

Circuits and Codes

The circuit and the codes are the simplest part for the inflatables. Though used many wires, the circuit itself is intuitive, and the most parts are merely repeating process. Just to connect the motor pump with a resistor, a transistor, and a diode. The code is also straightforward. Something to notice are that the motor pump has no polarity, with the middle pump inflating and the side one deflating.

Baking Paper

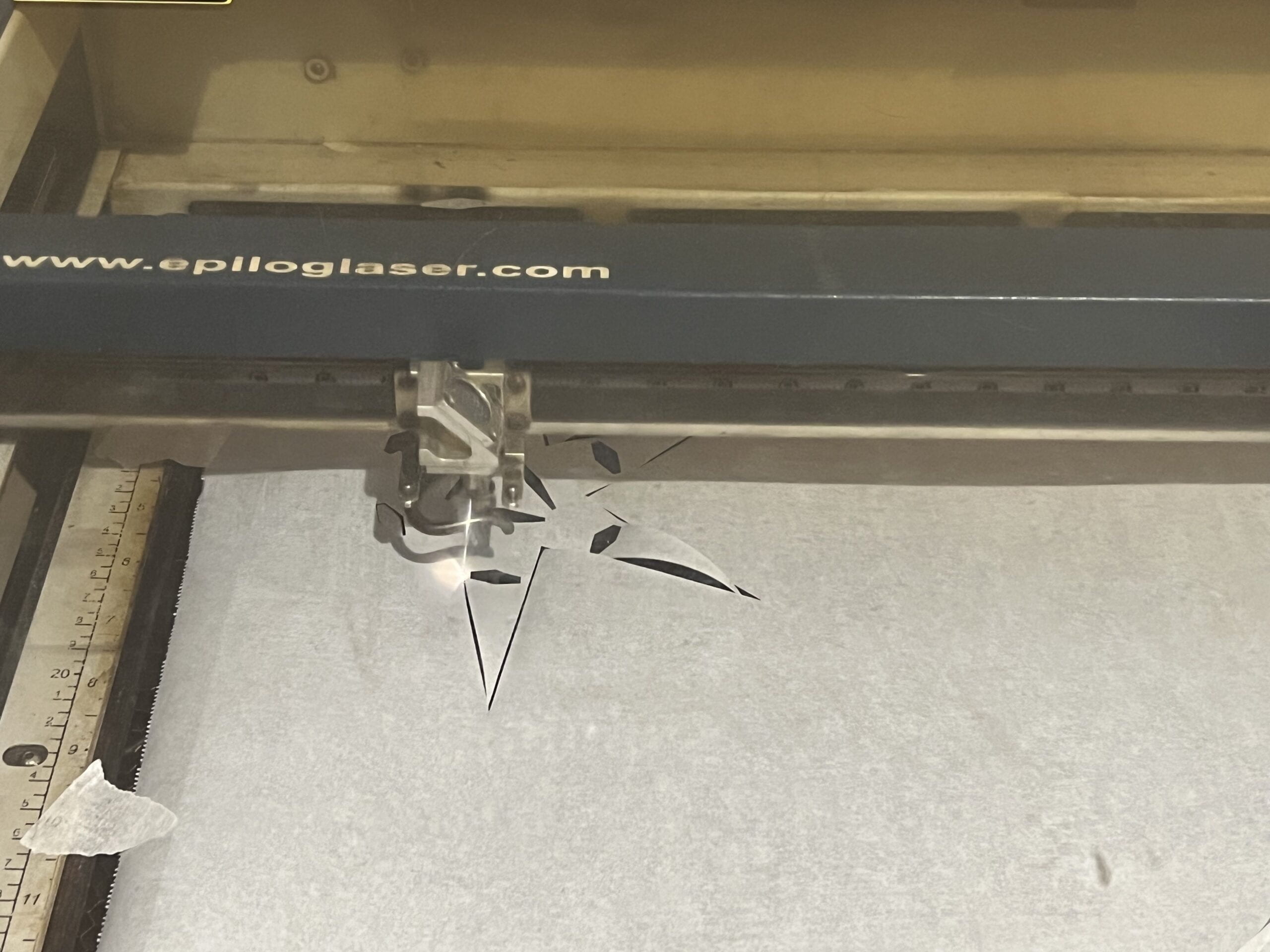

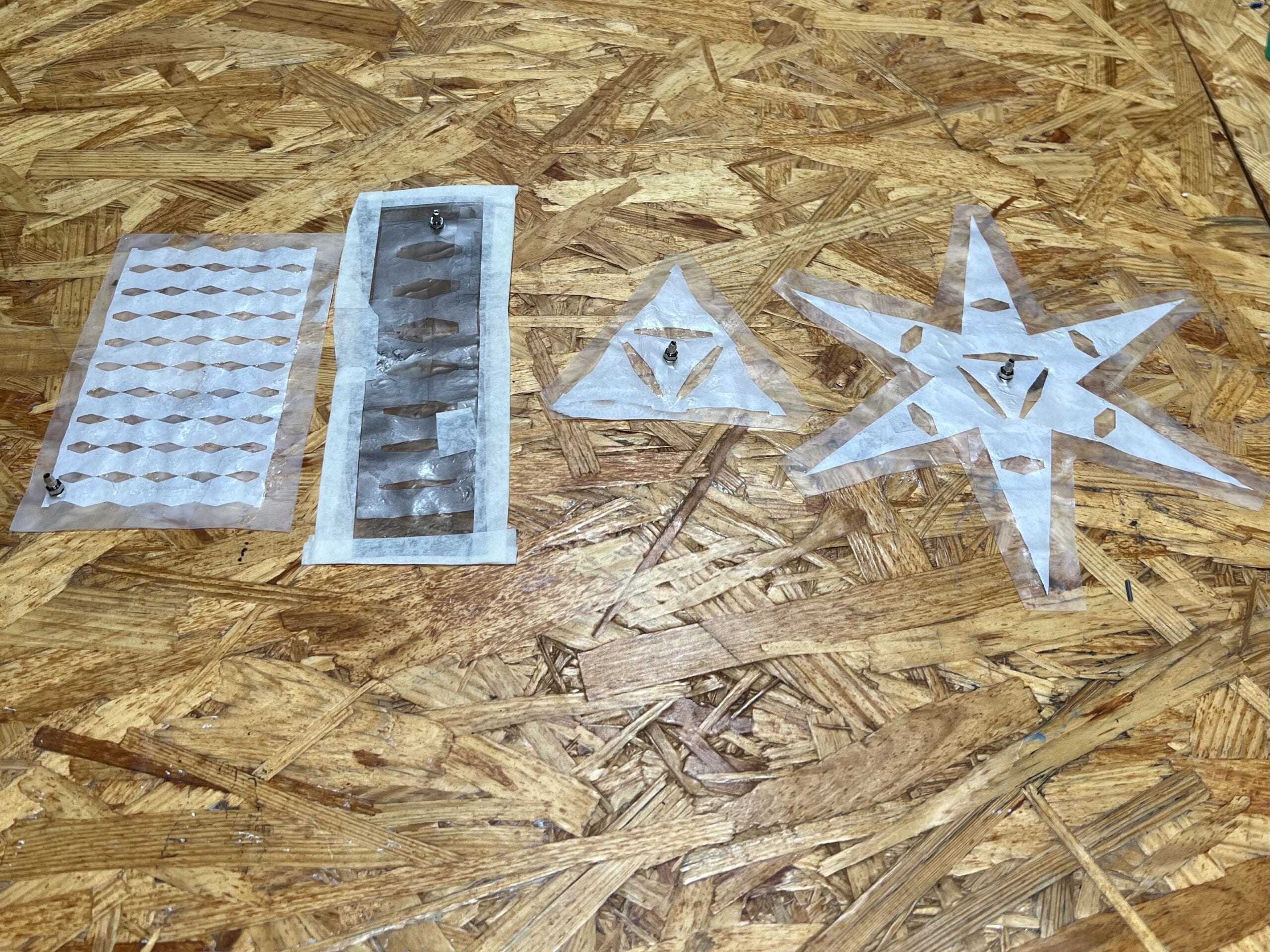

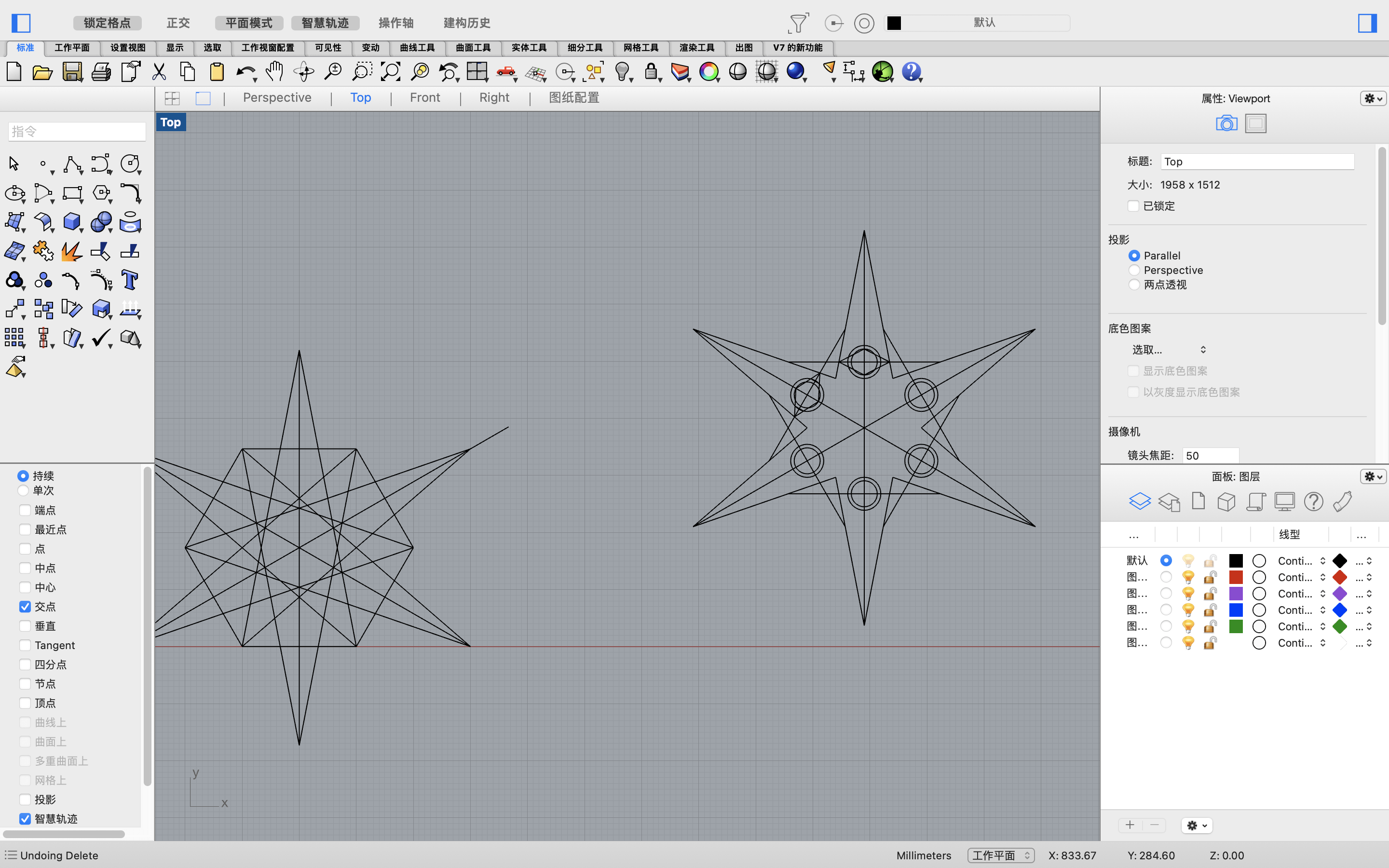

Cutting the baking paper is the first difficulty in this assignment. After creating the shape in Rhino, and transform the file using “canvasworkspace.brother.com”, I used the vinyl cutter (ScanNCut machine) to cut baking papers. Several problems could happen with the vinyl cutter. The first is when the baking paper is not firmed attached to the paperboard, then the baking paper could probably band in the cutting process. The second is when the paper tape used to attach baking paper is too thick, then the machine could also mess the cutting process up. The third problem happens when too much glue is applied to the baking paper, then baking papers would get wet, and get wrinkled.

After failing for several times, I succeeded in using that machine, but some minor problems would still happen from time to time. Then I tried to use the laser cutter, which turns out to be much more promising. After attaching baking paper with the machine using paper tapes, the laser cutter could cut the shape quick and accurate.

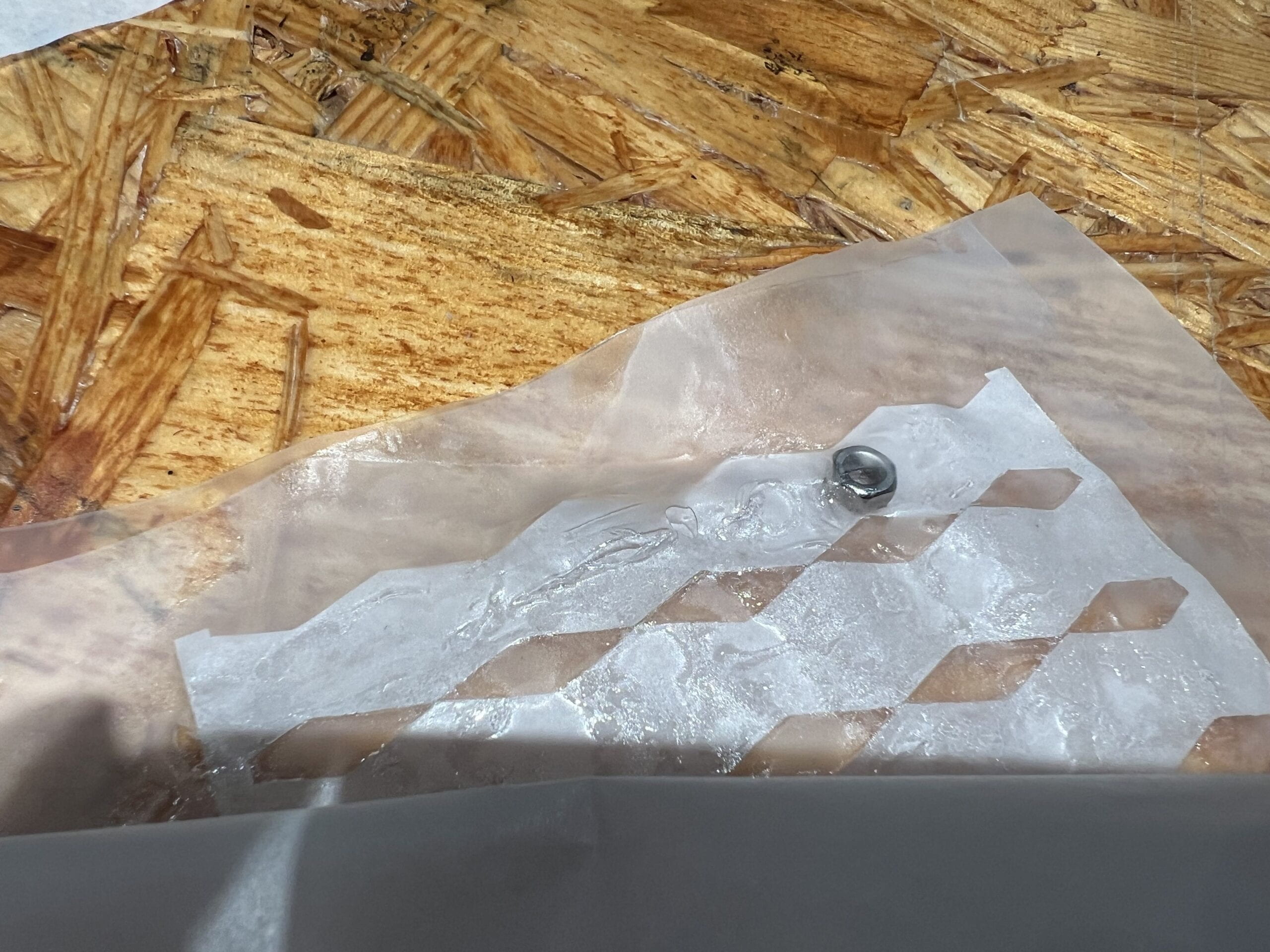

Sealing the TPU

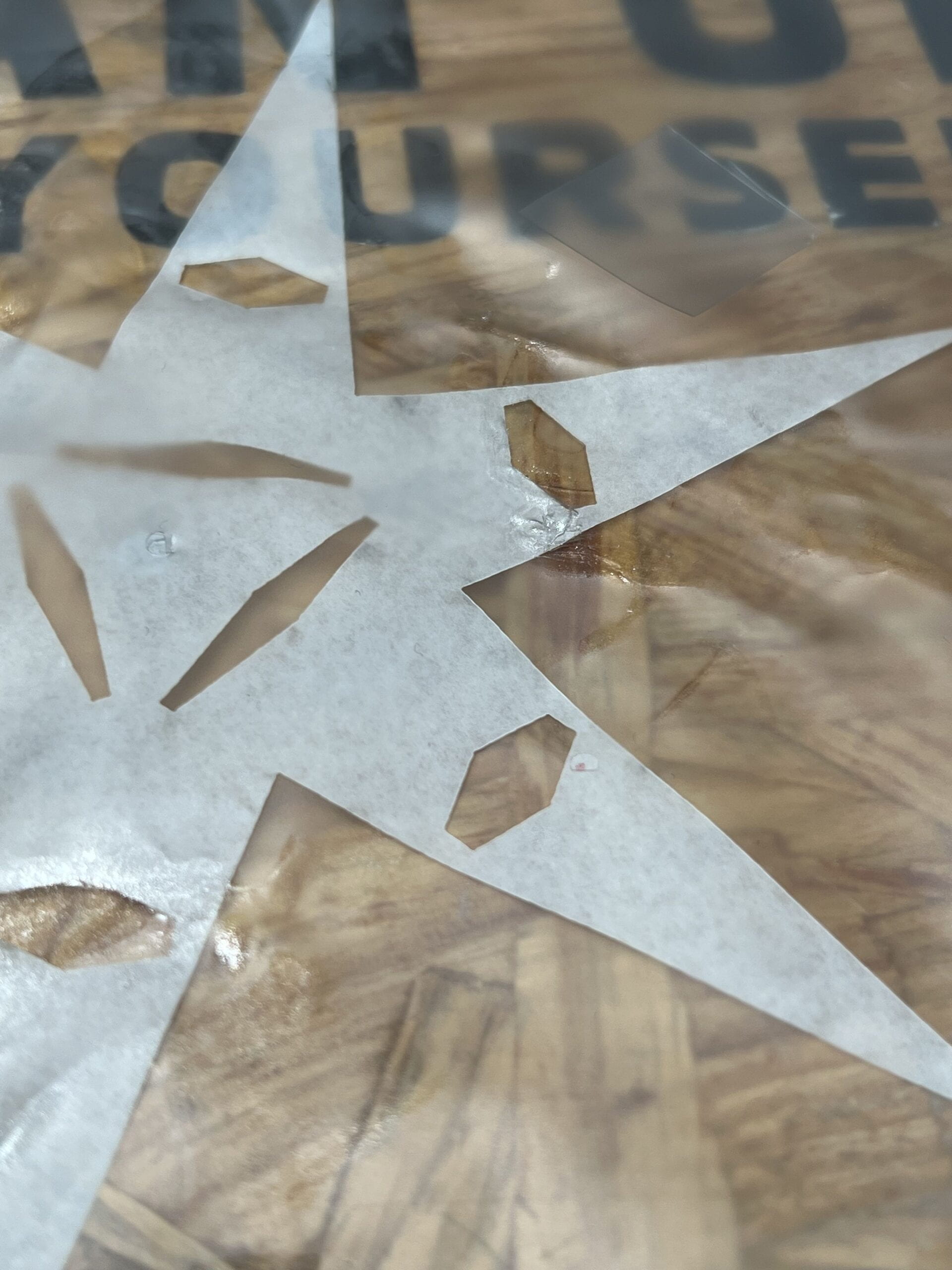

The heat sealing is the most frustrating step in the whole process. I used iron to heat the two layers of TPU, sealing everywhere except those covered with the baking paper. Two major problems I met all the time are: the TPU are not securely sealed, especially for the small gaps between baking papers; the TPU melt due to the high temperature, leaving holes on it.

The second problem was rather easy to solve, I could add another layer of TPU on the hole to seal it. But such practice would also make the inflatable more messy. The first problem is the one I spent most time on. I used the iron for hours trying to seal every corner, but it just does not always work. Later I found that the smaller iron is much better to use compared to the normal size. The smaller one could seal the gaps more accurately.

After finishing all four pieces, I found that there is this super machine that could automatically heat seal the TPU within ten seconds. And the result is very perfect, that every corner is sealed, flat and neat. I really look forward to trying this machine in the future.

Final Pieces

I made altogether four pieces of inflatables, three are copies from the essay, one is an original design.

In the process, several lessons are learned. First, don’t make the margins of the baking paper too thin, if so air might not be able to go through, thus the rest of the piece would not inflate. Second, leave a rather wide platform to place to valve, so that the little iron circle would not block your way sealing the TPU. Third, never stay too long at the same place when ironing, the TPU would probably melt.

The first piece worked for a while, and it leaked afterwards. The gaps between baking papers are too thin, so that air cannot go through easily.

The second piece was a complete failure, everywhere of the TPU leaked, I sealed again and again, but not solving the problem so much. Even with paper tapes to seal the margin, the piece still does not function fully.

The third piece was the most successful one. It could inflate as designed into a 3D tetrahedron. I leave every gap and margin big enough so that it worked well. With the smaller iron, the sealing process was also much smoother.

The fourth piece is my own design. I did not really have a clear pattern in my mind when drawing the shape on Rhino. After drawing so many lines, I decided to make a “star”. I also tried to explore the different directions of banding, by sealing the piece using different sides, three poles were ironed in front, and the other three were ironed at back. But the final result does not sure a clear pattern of inflating in different directions.

The overall making process of these inflatables are not very pleasing, with so many problems in each step. But I think with the laser cutter and the bread-baking like machine, the whole process should be much easy and more efficient.