This project is about making a tiny food tray from the very beginning using different machines and tools. It’s really fun to make something using my own hands though the tray is a little bit too tiny for real usage.

Fabrication

Several machines and tools are used during the fabrication process, involving the band saw, drill press, router, finishing oil and a lot of sanding.

Band Saw:

The band saw is used to cut the basic shape of the cutting board. I cut the outline appearance of my board, for those parts that have sharp curves, I used reliving curves that helped me to turn the saw easily and have batter curves.

When using this machine, I found out that making smooth curves is harder than I thought. Since the saw is really narrow, it’s very sensitive of the turns, I have to turn the wood greatly, sometimes more than 90 degrees to get a smooth curve I want.

Also, one flaw I made with this machine is that I started the cutting in a big angle, not being able to control the saw perfectly, I cut into the shape I wanted. Andy told me later that the better way is to start the cutting at small angles, cut it from parallel. After getting to know this trick, my later cuttings are much better.

Drill Press:

The drill press is used for making holes on the wood. There are different sizes to choose from. This machine is not hard to use. The time used for set up is much longer than the real drilling process. After setting up everything and fixing the wood, pressing the drill is easy and intuitive. I didn’t need to press as hard as I thought when drilling the hole, and I can speed up the drilling process simple by pressing a bit harder.

There is a special sound when the wood piece is drilled through, also my hand holding the reel can also feel it. So, it’s easy to find out whether the hole is complete.

Disc Sander & Belt Sander:

These two sanders are used to sand the straight side face or outer curves. I didn’t use the belt sander this time, but I used the disc sander a lot to shape my curves. This machine is very useful in making beautiful curves that the band saw might not cut.

One thing I found out when using the disc sander is that if I kept sanding the same position for too long, the wood turns black. This is might because that the temperature turns high and burnt the wood. So, I need to keep moving the wood piece when using this machine.

Oscillating Spindle Sander:

This machine can be used to sand holes and inner curves that the disc sander can’t cover. There are multiple radius of the sanders to choose when sanding different size of the holes or curves.

This machine is not hard to use, but it’s not that stable and keep shaking when it’s turned on, so I need to press harder to hold the wood piece. Another thing I found out when using is that, when the dust collector is turned on, it would keep inhaling air at the center of the spindle. So, if the radius is small, the dust collector might inhale the wood and makes it difficult to change position or lift.

Random Orbital Sander:

This sander can sand the surface of the wood. By changing sanding paper of different grits, the sander can have various of outcomes. This random orbital sander is much heavier than I thought, and it’s also not so stable since it’s rotating the sanding paper in high speed.

One thing happened when I was using this sander was that I fix the wood on the table, but I made it too hard that the side face of my piece is damaged by the fixer. So, I needed to use the oscillating spindle sander again for the side face.

Sanding Papers & Blocks:

I used sanding papers and blocks of different grit to smooth the edges and the side faces. I used 240pp, 320pp, 360pp and 600pp. As the grits get higher number, the surface becomes smoother. And it’s really exhausting for sanding by hands!!!

before sanding after sanding

Router:

The router is used for cutting the edge of the wood piece in order to get rid of the sharp angle and have cute edges. There are many different types of edge to choose from, I just choose the normal rough one, which fits my piece. I used the router for one side of the edges and both sides of the hole. I tried and practiced on a sample piece to test the height of bit before having that on my wood.

I think the router is the most difficult machine to use in this whole project. I have to hold the machine myself, since the router is heavy and it moves along the edge, it’s not stable at all. Also, I can’t see the exact situation when shaping the edges.

During the process, I burnt several places. Also, after reposition my piece to route the other half, the height of the bit changed a little itself, thus the edge shape is not the same for the two halves. I spent a lot more time on sanding the edges due to that.

Finishing:

Mineral oil and wax are used for the finishing. This part is the easiest during the project. All I have to do is to pour the oil onto the wood and clean it up afterwards. There’s no much space for me to make mistakes. The wood color changed a lot after the finishing.

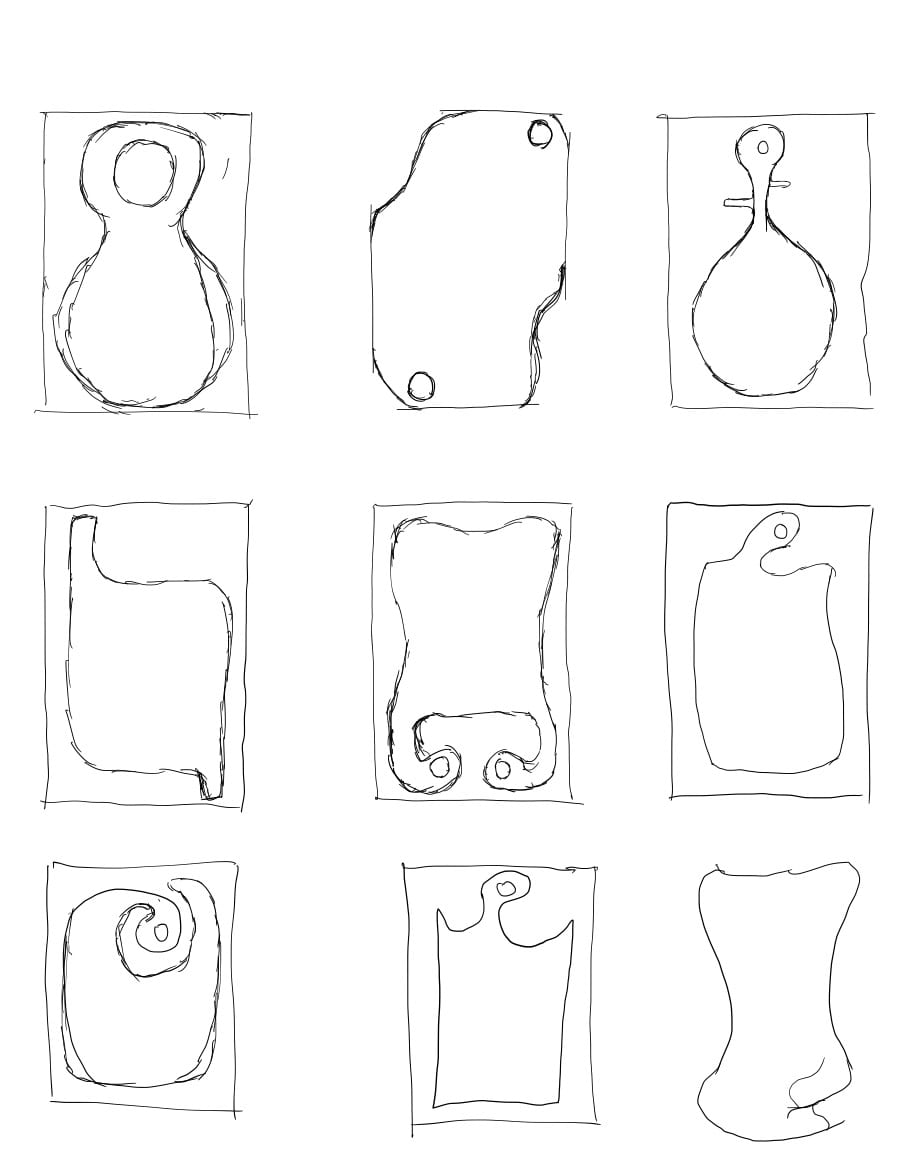

Design

I drew several basic patterns on the class, and just picked a good-looking one. After seeing my classmates’ design, I thought about about shapes and drew a whale. I spent quite a long time deciding to adapt the original one or the cute whale. The origin design won over the animal at last because I think the ring shape can be used as handles or lift something round, like an orange or a tomato.

When making the design onto the wood, I found it really hard to draw the symmetric pattern, luckily, the final piece looks quite symmetric and balance.

Reflections

1. Knowing what you know now, if you were to start over again, would you make any changes to your original design design? What is advice that you would send to your former self?

I would try to design something a bit harder to make. Since my piece is rather round and all about curves, it was not difficult to cut and sand. I think I would design more elements, like corners, angles and small shapes.

Advice would be that I can challenge myself a bit more, and accept the fact that there would definitely have mistakes and flaws during the fabrication. Not everything in my mind can be carried out perfectly. Plans can’t keep up with changes. And also, remember to pick a larger piece of wood from the very beginning 🙂

2. If you were to build a similar project, what would you keep the same from this project? What would be different?

I would keep the ring shape of this project, this shape is really handy and good-looking, the process of making it was fun, too. However, I would change to shape of the upper part, adding more designs to it. I’d also like to change the edges, the edges used in this project was the normal round one. I want to try some new edges using different bits of the router. Furthermore, I can try different shape of holes instead of the round one made directly from the drill press.