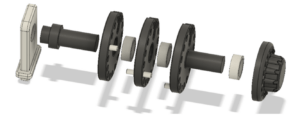

During this meeting, I continued to assemble and print the other components that were required to build the lock. I tried combining the stl files into one in order to increase the batch of printing that could be done in one go.

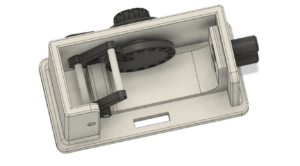

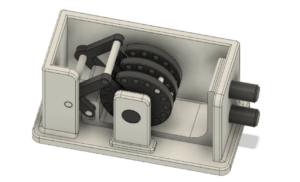

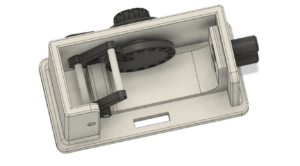

During this, I tried printing the larger components of the combination lock such as the outer frame and the larger components on the inside of the lock.

During the meeting, Amy pointed out that I did not print the base for the cardholder so I copied the file and started the print on the device which told only around 30 minutes.

For this combination lock model project, I plan to learn more about the process that goes within 3D printing a model and moreover, assembling the different parts for that specific model. For the next and last week, I plan to have all the components printed and plan to assemble the combination lock in its entirety.