#Blog 10: Project 2

Project Title: Glowworm Continued: Spinal Cord Mechanism

Charlotte Xu & Younian Liu|Professor Marcela Godoy

Fabrication & Production

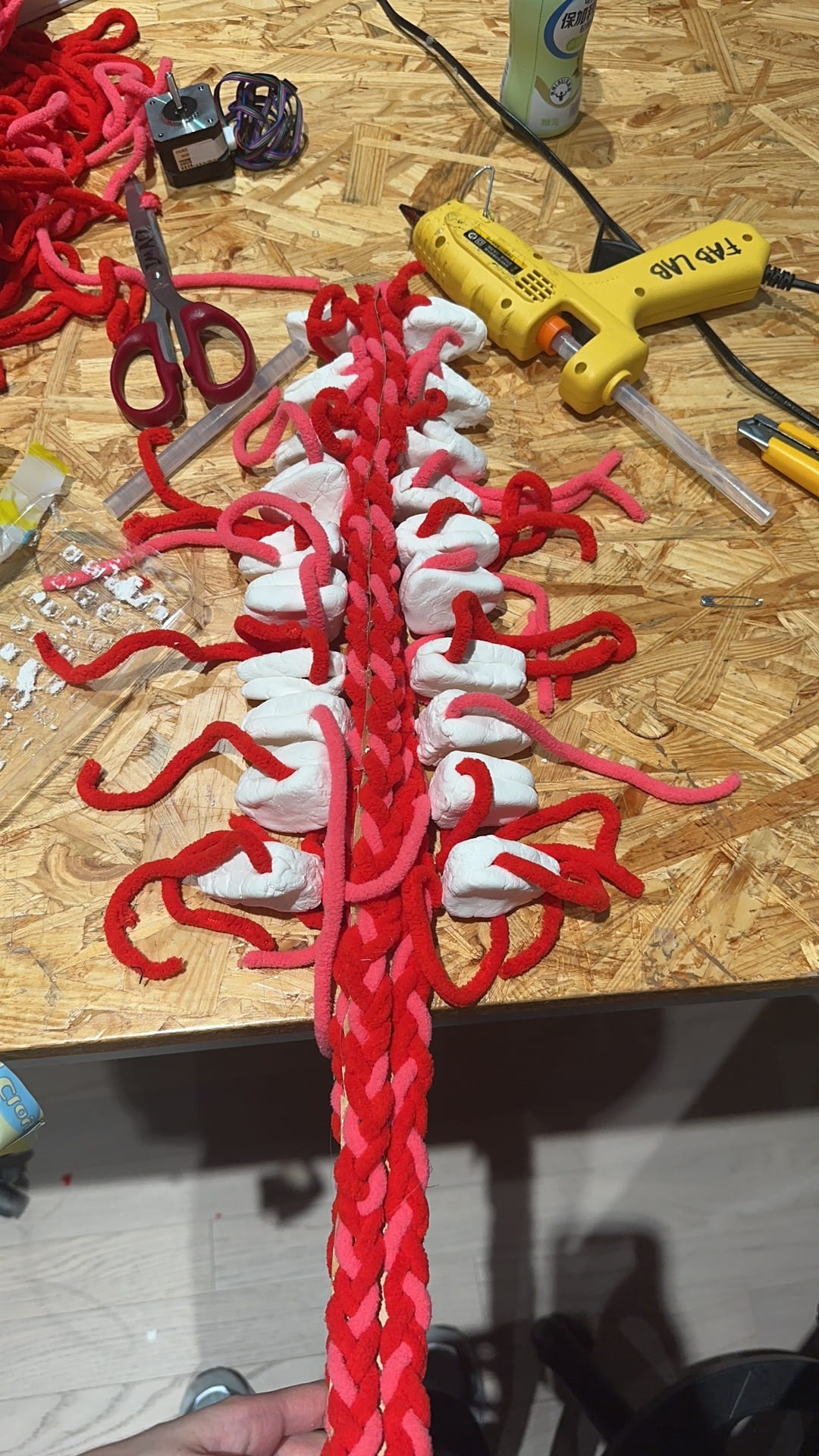

Based on the previous project, we continued to work on Glowworm. Inheriting the previous concept of soft emotions and cruel natural selection laws, we still decided to use wool and paper clay (prototyping the hard materials) to hand-made the spine. This is the first attempt:

At first, we let the pressure sensor read the value directly and reflected it in the motor movement, but under Marcela’s guidance, we realized that it would be better to use the pressure sensor as a trigger since the audience is not able to observe the subtle change of the force we put on the sensor, but rather whether or not we are touching the sensor. So, we changed the code.

Original code

Code we are using now :

This is the servo movement:

To immobilize the spine, we designed a neck collar to make the whole device wearable. For the actual object to be moved, we used paper as a medium to connect the wool to the bone because based on our previous prototype inspired by a wooden crocodile toy, paper is a relatively more flexible and movable media. We wrapped the wool around on the outside, but when it tried it out, it seems that it was a little too thick to allow the whole device to move flexibly.

Since we are not sure about the exact problem of this attempt, we made a scaled-up paper prototype again the same size as the woolen one:

Through this trial, we found that there are mainly 3 problems:

- The distance between the bones and the bones is too large in so they cannot touch each other to drive the motion. This can be solved by adding small pieces in between the original bones.

- The friction between the back and the bones are too huge to move freely. We found that it was difficult to return the paper to its proper position after bending. This can be solved by adding a frame for the core so that it won’t touch the back and the motor should be placed on the top to provide larger motion.

- The motor is doing the curved movement and we swing the wooden crocodile toys when the action is actually a little different, perhaps better for linear movement.

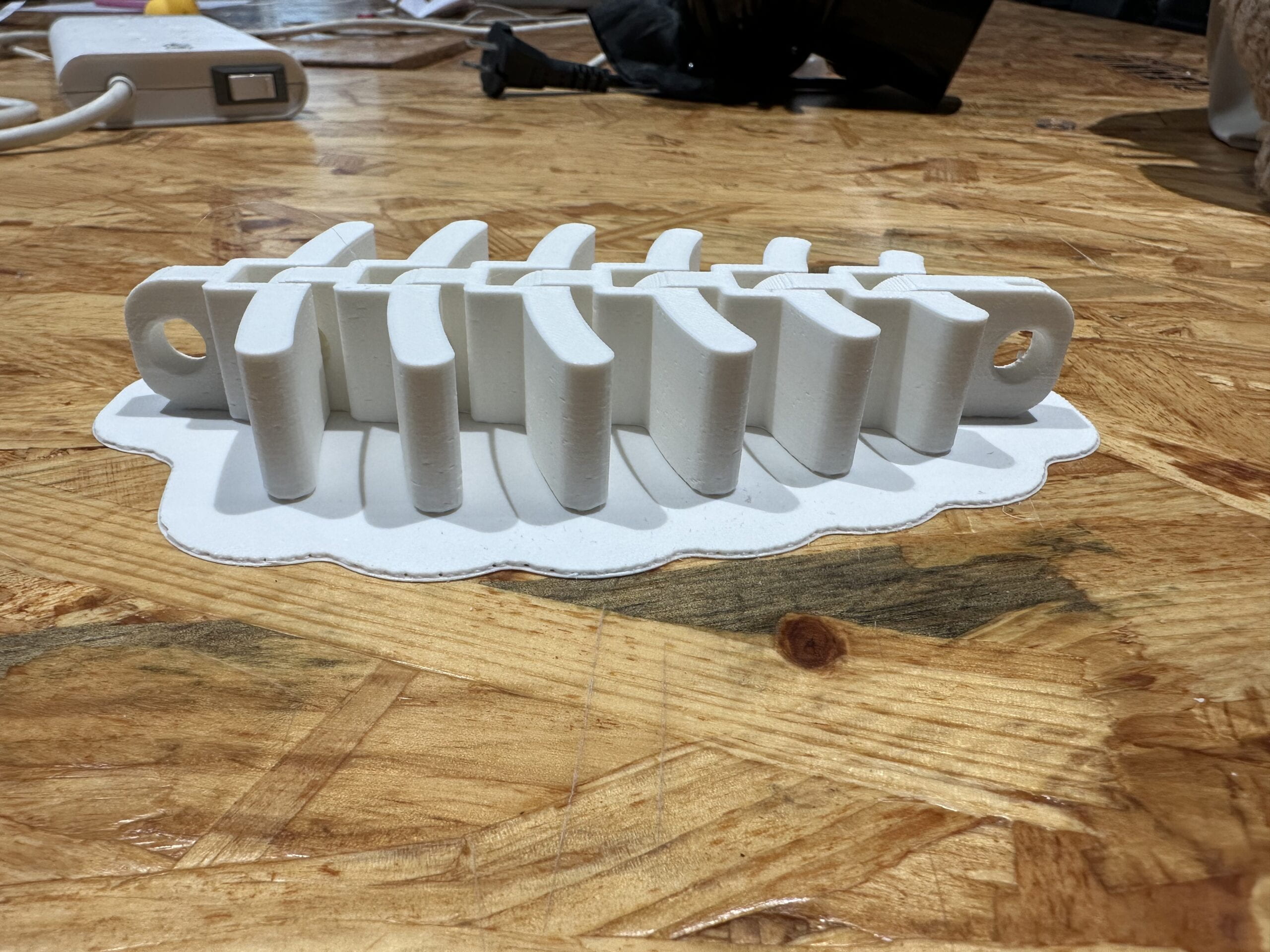

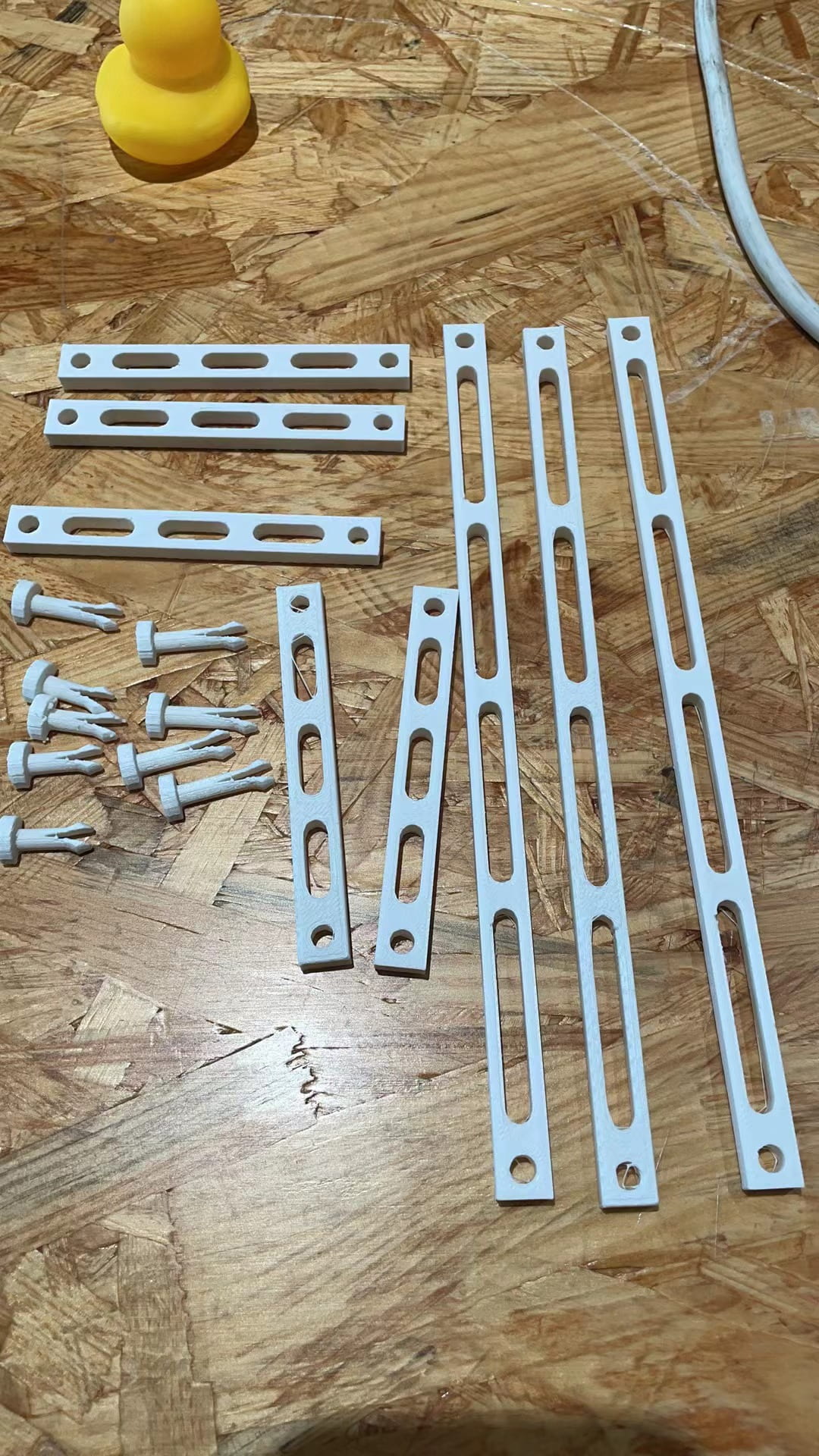

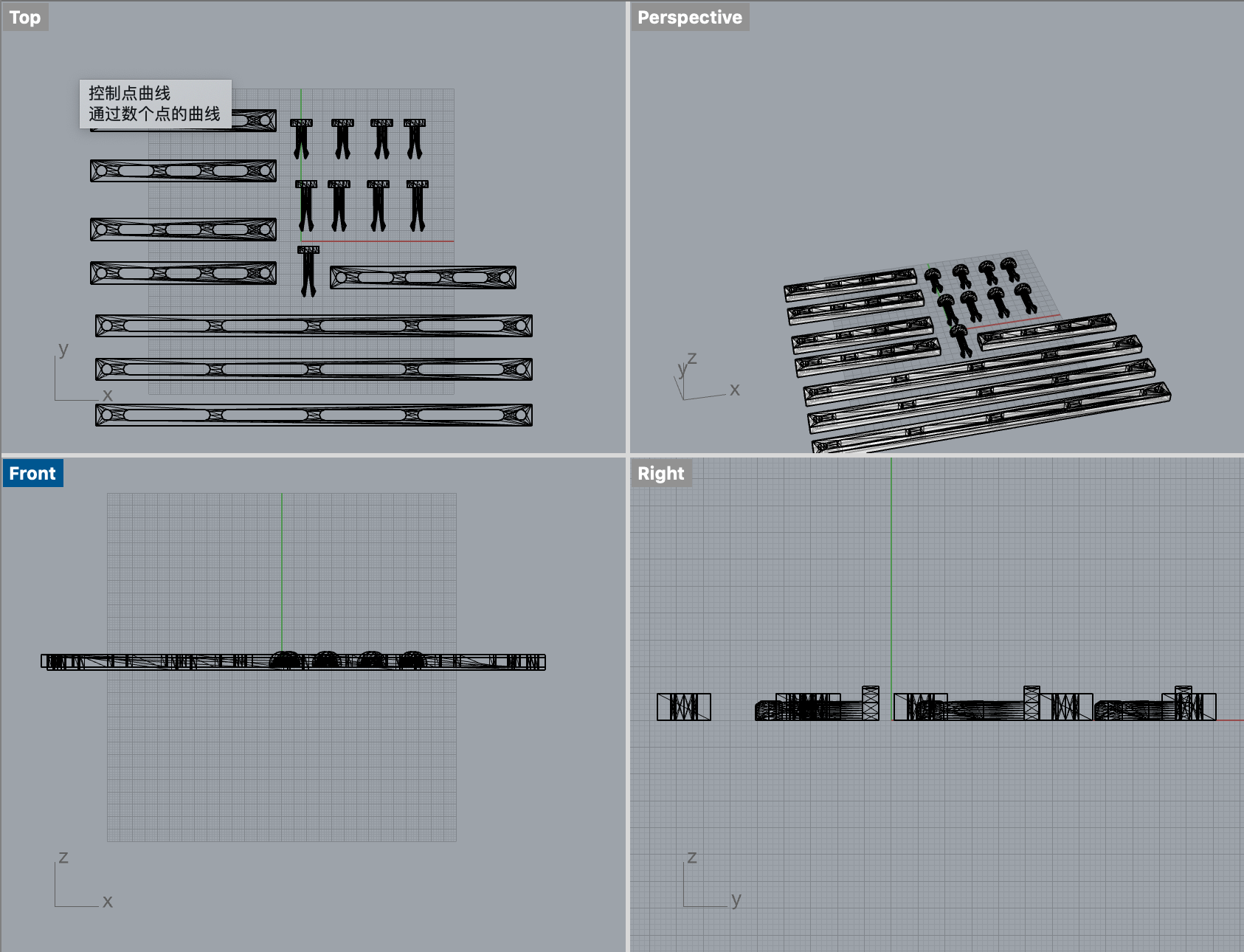

In addition, the handmade paper clay model is too random and lack stability, so we hope to improve our prototype through 3D printing.

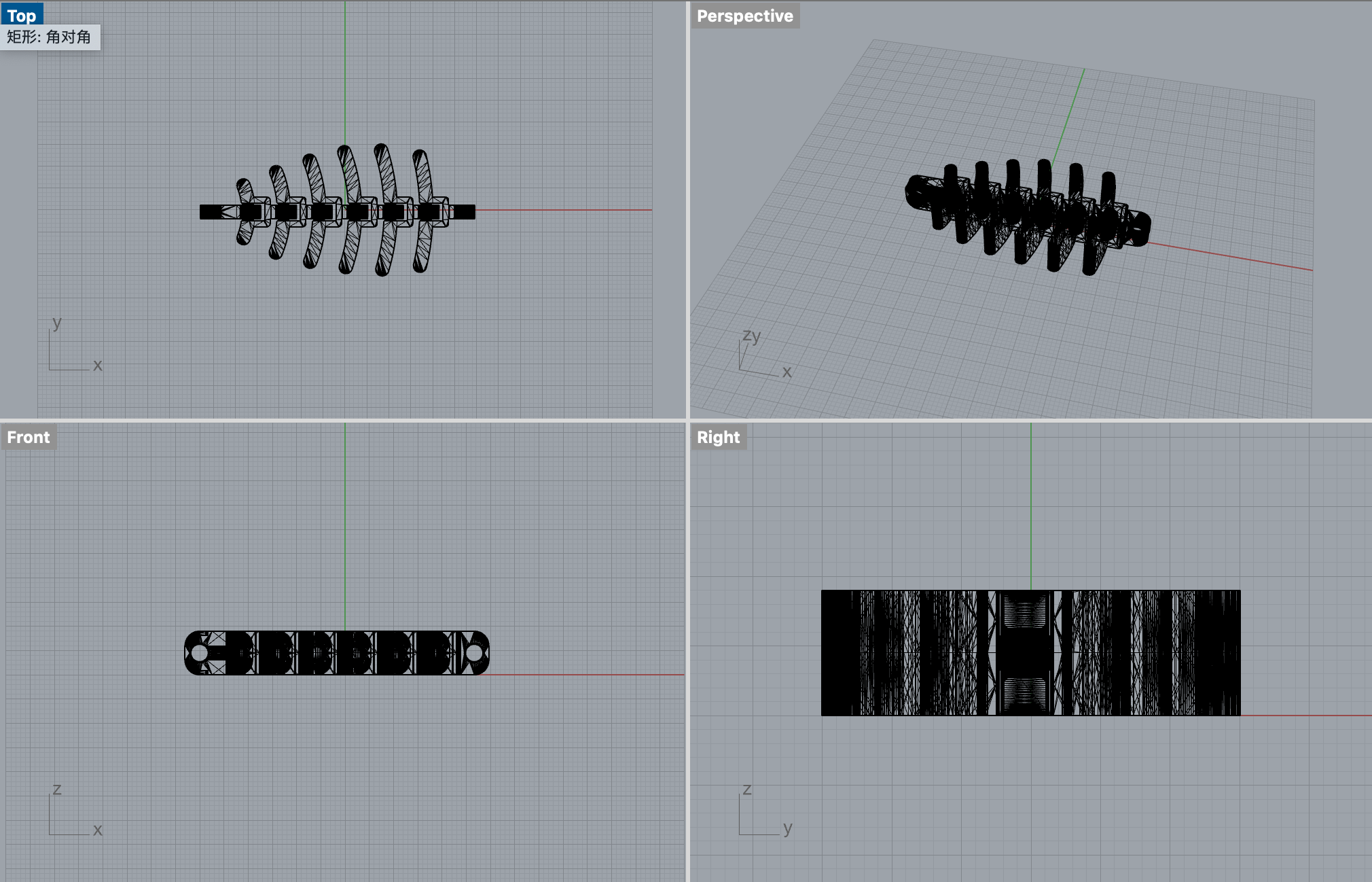

We found a model of a fish skeleton on Thingiverse, replaced the scale and trimmed the parts to make our new version of the skeleton prototype, and learned how to use the 3D printer in the process.

We tried to change the position of the motor to put it above, so that gravity will have less impact on the device. Now the model can be returned to the right position.

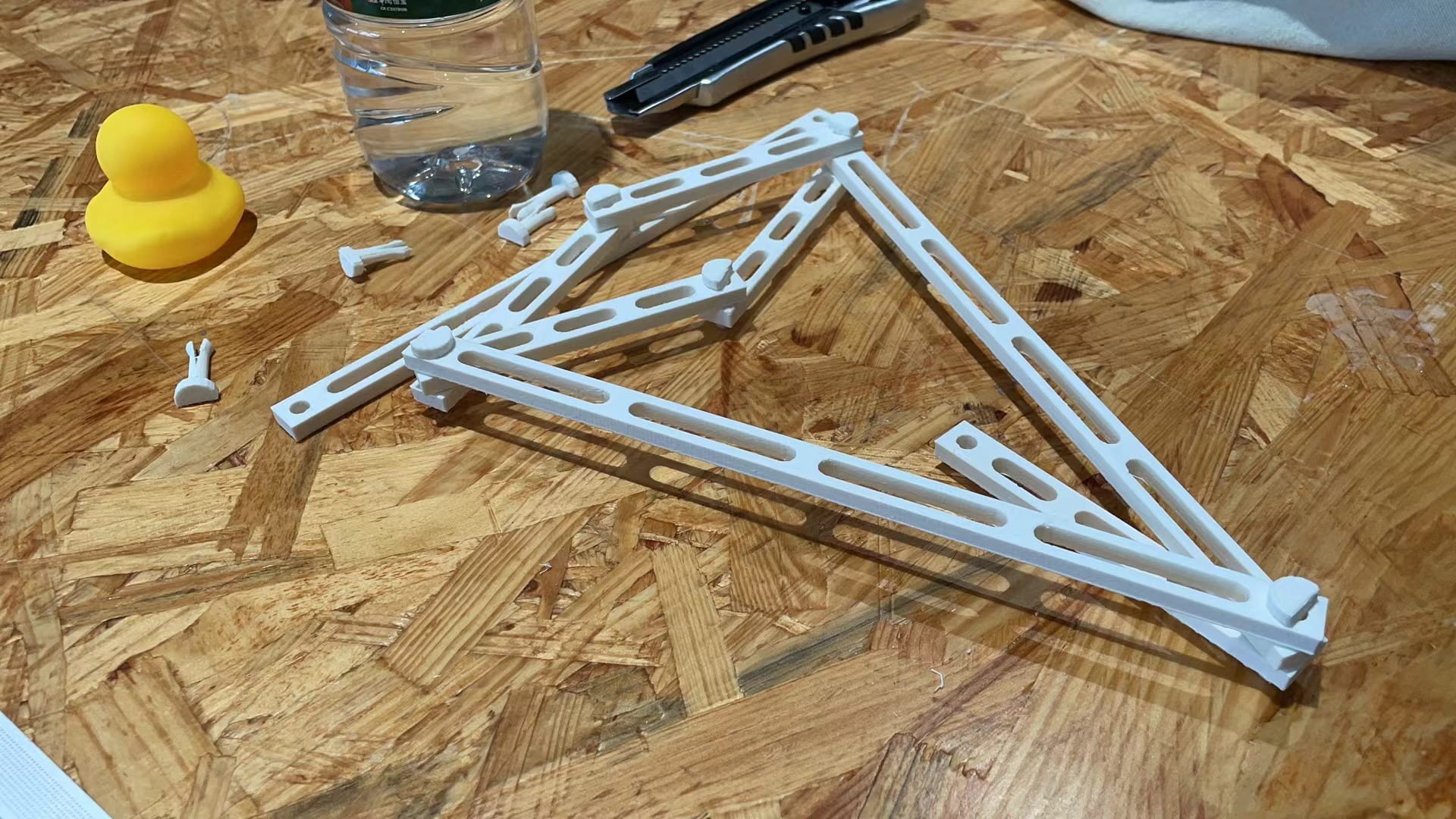

In addition, in order to transform the curved motion of the motor into a linear motion, we looked up information and found the Peaucellier-Lipkin Inversor.

We found an approximate model in Thingiverse and improved it (adding slides and make the model consistent with the theory)

REFLECTION & FURTHER INPROVEMENT:

- For further improvement, we would like to make the model of the motor part smaller and the spinal cord larger so that it can be worn on the body.

- We need to replace the design of the skeletal joints so that they can be naturally connected to the motor part.

- We will need to find a way to attach the mechanism stably to the body.

- We will adjust the 3D model of the fish to spinal core.