Design

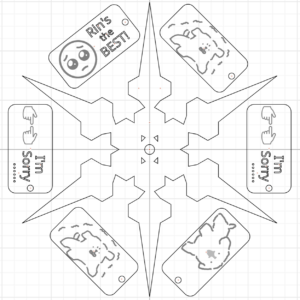

Attached to the shaft

– by me

I tried to make the most use of the materials. So, I designed something for myself in the blanked area.

And the most important lesson that I learnt in the process, reminded by Andy, is that for laser cutting we should be extra cautious with the font that we’re using.

And stencil is thus a good option, avoiding the middle of the texts to fall off.

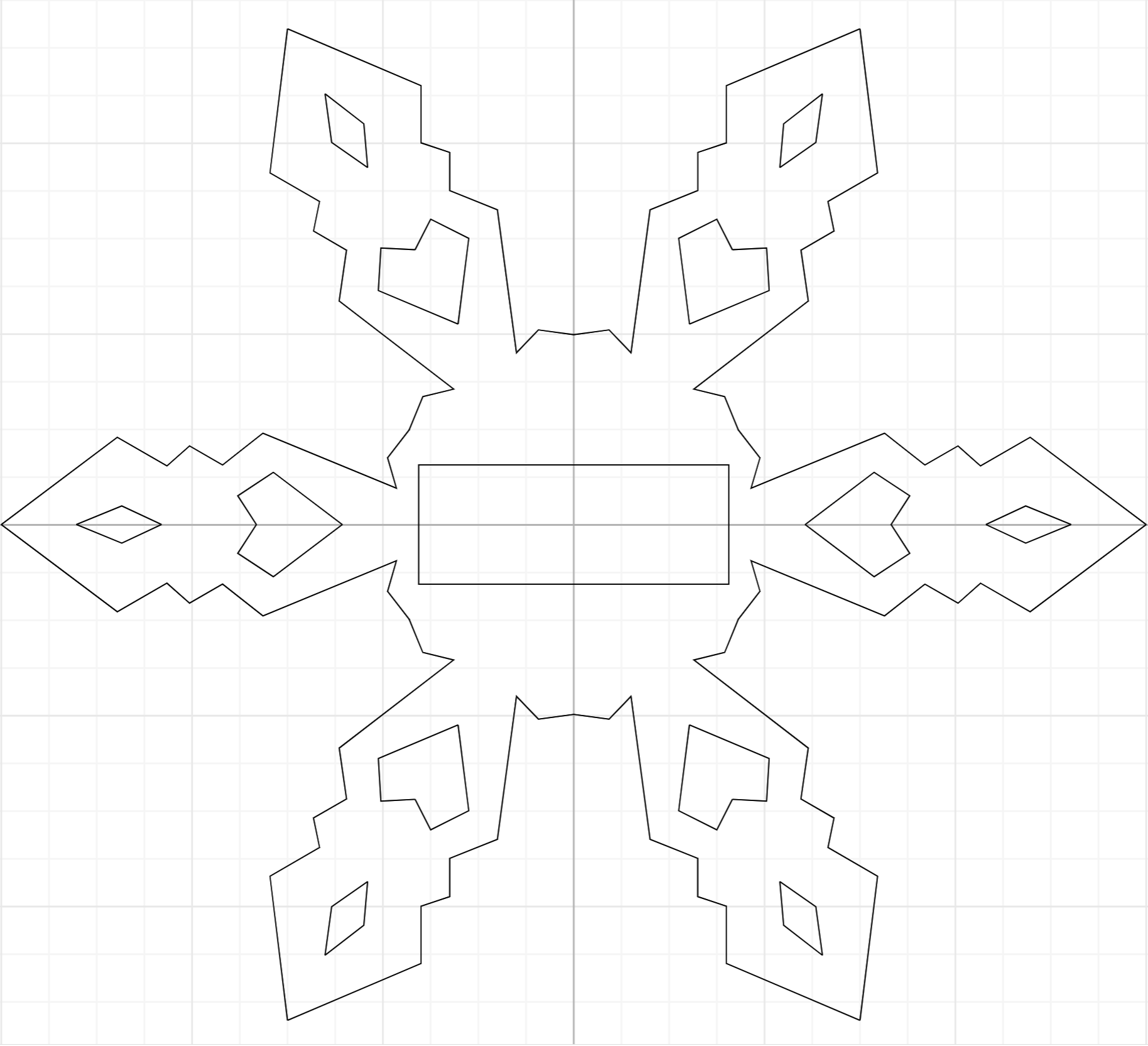

Attach to the stand

– by Rin

Laser Cut

Engraving mode.

The movement of the printer nozzle is shify. It’s pretty amazing thinking of how the motors exhibit great precision in such a high speed.

Cutting mode.

There’s nothing surprising with the cutting, though it’s undoubtedly spectacular. And also, it smells smoky. On the top of that, there’s inevitably trace of burning all along the cut. We have to polish or wash them off. Though this may be equally another kind of aesthetic.

All wrapped up

This looks kinda amazing, though it’s not necessarily an interfering pattern. One way to make it more impressive, is perhaps turning it faster. However, I am not sure how to realize that on a servo motor. So, I decided to leave with what it is right now. At least we grasped a basic idea of how digital fabrication work, partially.

Leave a Reply