STEP 1.

Design of the holder was respectfully easy because there were no complicated corners or multiple lines that needed to be considered since it’s just an rectangular shape. My teammate was Tawan and I was doing the work of a student A.

Here is the results of the first design:

STEP 1.2

- This was the hardest part for me since at first I didn’t understand concept of not having multiple intersections since the laser will cut through them and the whole shape will fall apart. However, I was able to do a simple shape.

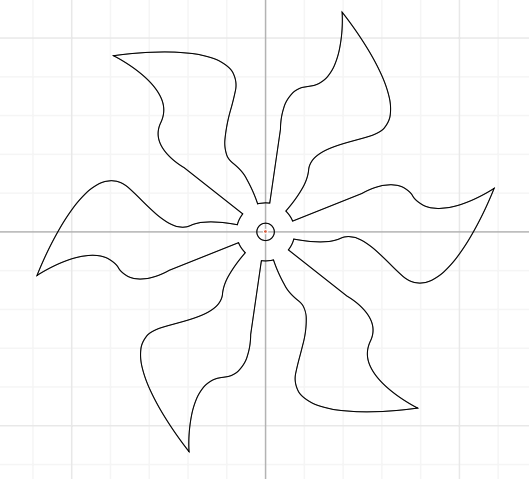

Here is the sign of the pattern:

STEP 2.

- For this step we were helped by the staff to insert the images we came up with and he turned on the laser which did all the work.

- An important thing that I learned during this process is the position of the material that the design will be cut on because the first time we cut the shape it wasn’t indented strong enough so it was hard to get the shape out and so the surface of the material should be straight.

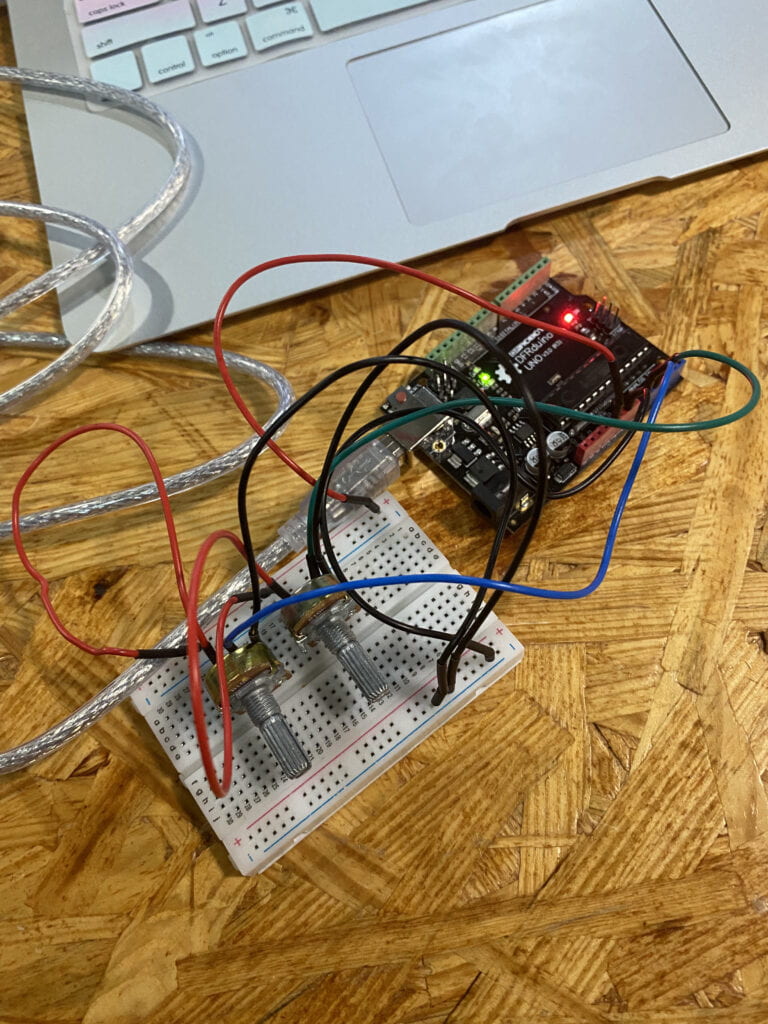

Here is our designs being laser cut:

STEP 3.

- This step was pretty straightforward we just needed to attach all the parts.

- However we did encounter a slight problem that the whole of the outer shape was a bit smaller than of the Servo, so I think there was some miscalculation in measuring the servo or during creating of the diameter of the whole.

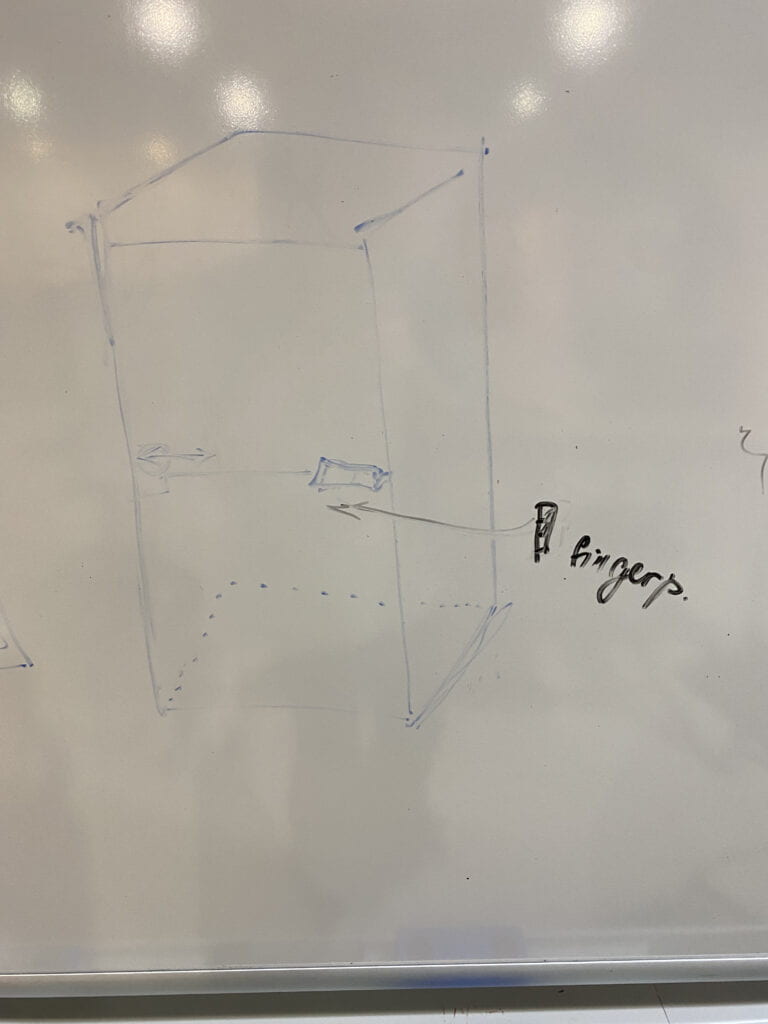

Here is the final work: