Final Product(temporally):

Raw Material: ABS pieces.

Step 1:

We built two wood frames to hold the melted material.

Step 2:

Looked up the destiny of the ABS piece, and measured the size of the wood frames and calculated the volume. At the end we got the amount of mass for the ABS pieces we need. Which was 166g.

Step 3:

Measureing

Step 4:

Put the ABS pieces in the frames, label them in the oven.

Since the frames weren’t tall enough, we had to add the ABS pieces separately.

Step 5:

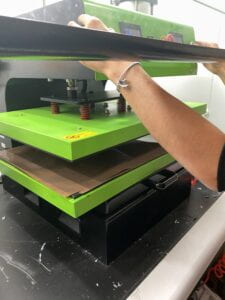

Compress the melted ABS pieces.

Step 6:

Form the shape and let them cool down.

(in the picture we put weights on it to apply force to the melted ABS).

Step 7:

Because the wood frame burned in the oven, it was hard to separate the melted ABS from the frame. So we had to cut the wood parts off.

Final Product:

Success and Failure:

The new material itself we made is a success, after a series of tests we made sure it is strong and reliable. It won’t brake easily, in fact I tried so hard and I still coulnd’t break it.

The failure would be setting the temperature of the oven to be too high that it burned the wood frame, also left burned marks on the material’s surface. That’s also something we can improve in the future.