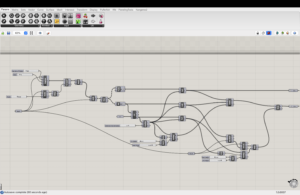

In-class assignment:

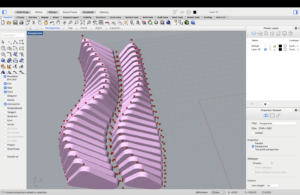

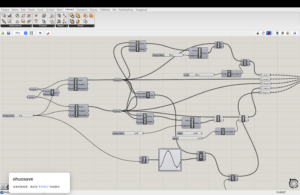

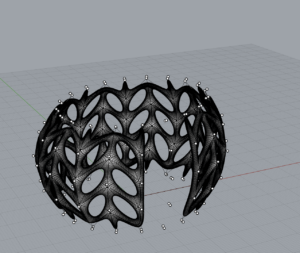

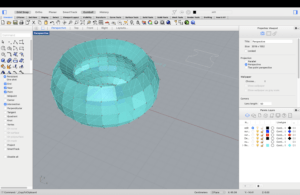

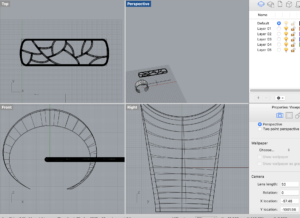

Grasshopper file

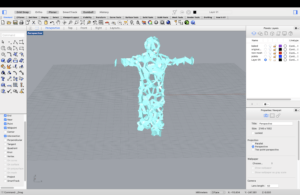

After-class Excercise Final Outcome:

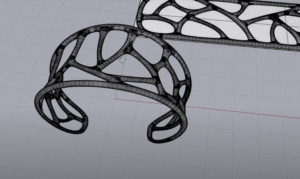

This is the exercise I did for the final project.

How to use digital fabrication methods in the making of the final project.

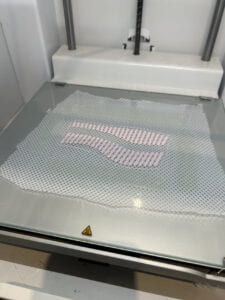

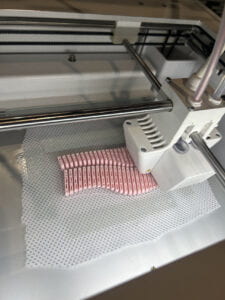

I intend to leverage techniques such as 3D printing and laser cutting to fabricate wearable device components, such as structural elements and decorative embellishments.

For example, I could use 3D printing to create customized components and desirable patterns for the waving mechanism, ensuring optimal functionality and aesthetic appeal. I can also utilize 3d printing on fabric to decorate the dress and make decorations like gloves or headpieces. Additionally, laser cutting could be employed to cut and engrave patterns onto the fabric or other materials used in the construction of the wearable device, adding visual interest and personalization. laser cutting can also be used to cut the structure for the mechanism.

Reference