instruction: https://wp.nyu.edu/shanghai-ima-interaction-lab/recitation-9-digital-fabrication/

Our task is to make an equipment in which a servo rotates one acrylic plate with the other acrylic plate fixed on the pedestal. We will design two acrylic plates, two pieces of wood and laser cut them.

Task1 Measure and Design:

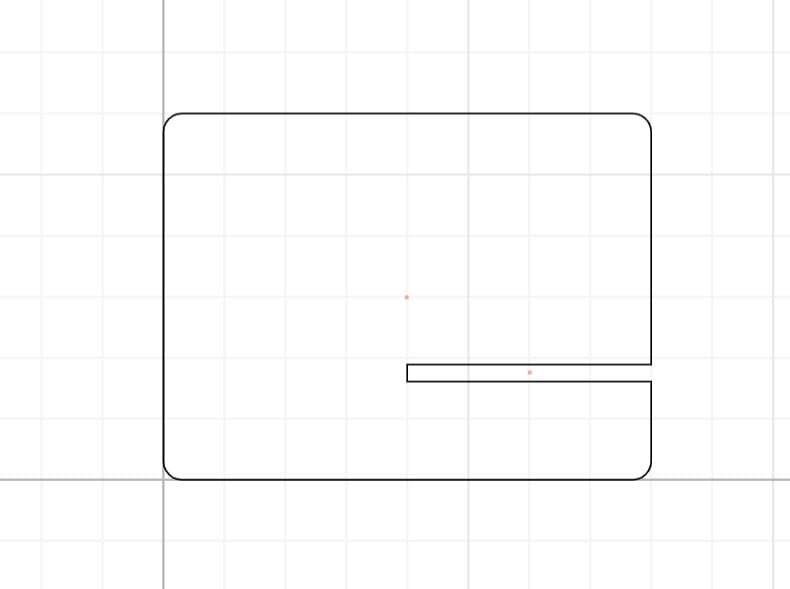

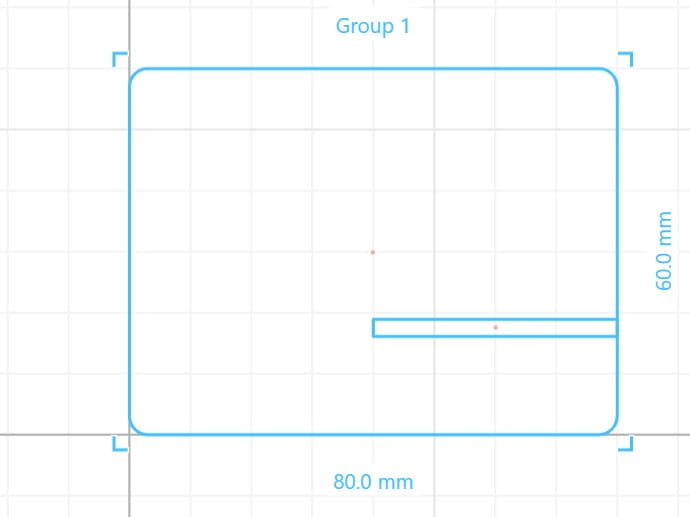

I worked with Andy. I read the data of outline of servo and told it to Andy and Andy designed it in cuttle. I also designed one part of the pedestal:

Task2 Design the pattern:

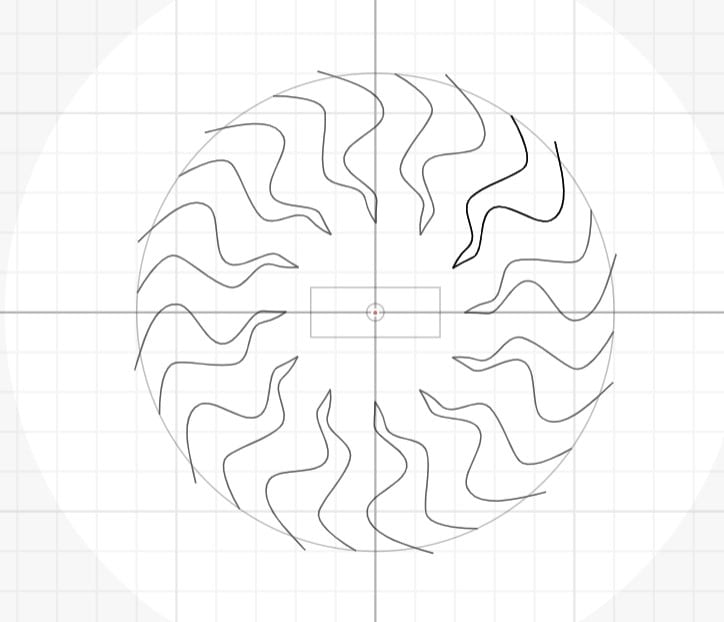

Now Andy and I need to design a circular pattern seperately to generate an art effect when rotate it. I didn’t do much sreenshots during design. I remember some points which worth referencing later.

- Don’t make too many nodes for curves, which make adjustment really hard later.

- Except changing the tangent line, I can also change the length of tangent line. A balanced tangent line will make the curve smooth.

- Don’t let the curves cross each other because we will cut it according to the line. Same when we rotation repeat it. An IMA fellows told me about it when I went to 823.

- remember that the curve will be cut off from the pattern and the pattern is what remained on the plate. Keep it in mind that what you draw will be removed.

After we finished designing the patterns, we realized that we have to curve a small circle and a big rectangle respectively on our pattern. Comparing our design, We decided to adjusting my pattern to fit the rectangle. So I move the two original curve and decrease the scale. Here is the final pattern:

Then we went to the Fabrication lab and watch the process.

The acrylic plate:

The hole was small, so Andy used his advanced fabrication knoledge to make it bigger:

Here is the final art effect:

Leave a Reply