Vacuum Forming Machine

For quicker prototypes from real-life objects, IMA FabLab decides to make our own vacuum forming machine.

COMPONENTS:

1. HIPS Sheet (the material for vacuum forming)

2. vacuum forming box

1. vacuum cleaner (need to be sealed, providing vacuum force)

2. sealed box with holes (for air to go through)

3. heater

1. warm air heater (to heat the HIPS sheets)

2. customized box with a cavum on top (to uniform the heat)

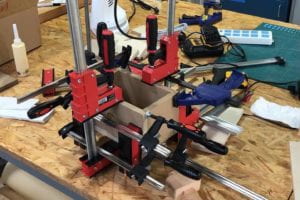

4. Sheet holder

1. frames of A4 size (to hold the sheet)

2. handles that match the size of the heater box (to fix the holder on the box)

3. clamps (to fix the material)

MANUFACTURER AND OPERATION PROCESSES:

First, cut the wood. Including wood pieces for 2 boxes, and also the sheet handler. For the big rect pieces, use the SawStop machine to cut, and for the small pieces, curve surface, and thick wood, we use the band saw.

Then, make the vacuum forming box. Need to drill some holes and the top surface of the box to let the air go through. And also, the box needs to be sealed to ensure the vacuum space can be formed.

Then, make the heater box and the sheet holder to heat the HIPS sheet. Here the key point is that we curve the handle to fit the shape of the heater box so we can precisely put the sheet so the sheet can be heated uniformly. Then, Need to turn to the highest temperature and wait till the sheet drip down about 1cm.

Last, place the object and do vacuum forming. This process needs to be done real quick. Open the vacuum machine as soon as your sheet approaches the object and push the sheet down to the box to create a sealed space for vacuum force. And also need to be done precisely so the sheet holder frame goes through the box edge.

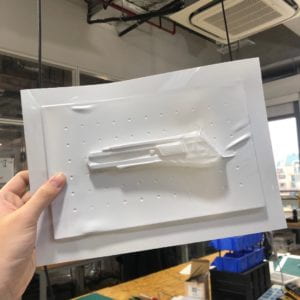

The result looks good! Even details have been formed.