Statement of Purpose

This semester, Lana, Jennifer, and I collaborated with Mr. Zhao from Garden No. 2 to create a product for the garden out of discarded plastic materials. We found via multiple conversations and visits to the garden that the most pressing issue the garden was facing was an efficient watering system across the garden.

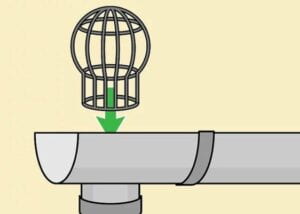

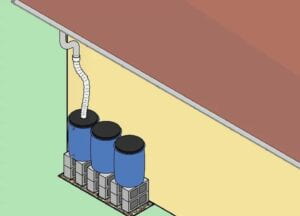

Mr. Zhao was thinking about placing a rainwater collection system on top of a building’s roof to solve this problem at the time. We initially assumed that developing a new watering system in the garden would be above our ability for this class, so we looked into other options, such as building a fish pond or a watering hose head. However, after receiving feedback from the class, we discovered that these proposals lack feasibility and utility. So, inspired by roof gutter systems, we concluded that installing a comparable gutter to collect rainwater would be the most possible and best fit the needs of the garden. We were challenged with designing a device that would successfully transfer rainfall into a collection bucket while also accommodating the garden’s physical space, despite material and location limits.

We made every effort during the semester to keep these goals in mind and to use them as the driving force behind all of our decisions.

Research and Development

https://www.youtube.com/watch?v=7oEEmDXPRLA

The film we created outlining the process with photos and videos.

Our making process:

We initially thought that attempting to tackle the garden’s watering system would be too complicated for our capabilities. We considered creating a tarp for a fish pond, a foot pumped watering hose, and a spray hose head instead of a full watering system. However, after receiving class feedback, we realized that these ideas were lacking in feasibility and functionality. So, we decided to reconceptualize our idea around the original issue of rain collection. After seeing a similar system using roof gutters that feed into a collection bucket, we were inspired to design our own gutter based on it.

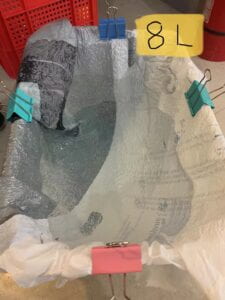

We conducted experiments to determine the best materials to utilize before starting to build the gutter. We initially believed that using water bottles because of their circular form would be great for creating a gutter, however, connecting them without serious leaking proved problematic. We were also discouraged from using water bottles because they are already well recycled. So, inspired by plastic coin purses, we decided to iron layers of plastic bags together to make a malleable sheet that we could mold into a gutter. Ironing plastic bags was a simple approach to achieve a specific thickness while retaining flexibility in making various forms. We cut various plastic bags into flat sheets and pressed the edges together to make a huge tarp. Based on the results of this experiment, we discovered that plastic shipping envelopes were the most durable material to layer and iron. We were able to achieve this by stacking plastic bags on top of one another.

We were able to develop a strong, leak-proof polymer that could hold water. As a result, we determined that layering plastic bags to make a waterproof and malleable sheet would be an excellent material for forming the gutter.

We utilized melted plastic bottle caps to construct a bespoke hanger form to hold the gutter. Shredded bottle caps were placed in a square mold, melted in an oven, pressed to form a flat board, and then carved out with a CNC machine. We began by designing L-shaped hangers to be drilled into the roof and wire-attaching the gutter to the hangers. Mr. Zhao was pleased with the project’s direction after witnessing our initial prototype but suggested we reinforce our gutter material and seek temporary installation techniques rather than drilling into the roof. He suggested that we roll the edges to thicken them so that the gutter would keep a straighter shape with less waning.

With this feedback, we modified our L-shaped hangers into S-shaped hooks that could hang on the fence while also supporting the gutter. This was a more adaptable alternative, allowing Mr. Zhao to adjust the gutter as he saw fit. We assembled the gutter onto the hooks with snap buttons after stiffening it with additional layers of plastic and folded edges. We discovered that the gutter had stretched upwards from ironing and did not allow for easy water flow after assembly. To rectify the warp, we had to iron the gutter to bend in the opposite way. Water easily flowed out one end after some trial and error. Finally, we were able to install the finished gutter in Garden No. 2.

Me Lana, and Jennifer worked well together as a team, with each of us playing a certain role. Me being the only native Chinese speaker, I assisted with all translations and keeping contact with Mr.Zhao. Lana largely focused on ironing the gutter, while I monitored the fabrication of the S hooks. For our final film, I created the voiceover screenplay, Angel translated it into Chinese, and Lana recorded the voiceover and edited the movie together. Throughout the production process, all three of us collaborated closely on conceptualizing, assembling, and prototyping.

Conclusion

This semester, our team collaborated with Garden No. 2 to build rainwater collecting gutter out of recycled plastic to help with garden watering. Finally, we were able to design a movable and adjustable gutter that successfully channeled water into a collection bucket. We were able to adjust to Mr. Zhao’s requirements by designing a system that could be relocated as needed along the garden fence rather than being permanently installed. Furthermore, by pressing several layers of plastic bags into our gutter material, we were able to transform fragile waste material into a solid, durable, yet malleable material with added usefulness. However, because it did not rain before we finished and delivered our gutter to the garden, we were unable to determine how well it would collect water from the fence. We would have been able to make additional improvements to the gutter’s functionality as a rain collecting system if we had more time to test it in outdoor conditions, such as modifying placement or size. I am most proud of the fact that we were able to share our work with the community and observe the immediate impact of our efforts. Knowing that our gutter would not only assist to alleviate the garden’s watering problem but would also serve as a reminder to neighborhood members about the importance of reducing plastic waste made it all the more enjoyable to deliver our work to Mr. Zhao. Hearing his encouraging and validating remarks in support of our idea validated all of our efforts. It warmed my heart to know that we had developed a pleasant relationship with him throughout the semester. Throughout the semester, I maintained close contact with members of our community and kept the group members informed. I learned that I was a fantastic communicator. Because of my bilingual advantages, translation is not difficult for me. At the same time, I was taken aback by the quantity of translation work required on my part.

This is a fantastic opportunity for me, and I am grateful. I can make good use of my skills and make a major contribution to teamwork.

I learned from our tight teamwork that open communication is the key to a successful group endeavor. Everyone was actively involved and motivated to achieve the established goals, which made teamwork much easier. Maintaining regular communication with Mr. Zhao was also essential in order to design something that would be valuable to him, such as switching our installation from drilling to hanging.

If we had more time, I’d like to see how effective our gutter is in collecting rainwater, as opposed to merely water directed into the gutter from a hose. We would have been able to incorporate these critical aspects from testing in real-world situations to produce something even more useful for Mr. Zhao and the garden. I would advise people working on similar projects to maintain active participation within the group so that you can work as an efficient unit. I would also advise them to be open to diverse points of view and to not be scared to try new approaches.