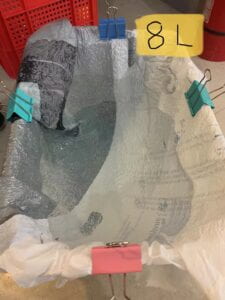

Pool trap

We pressed plastic bags together into a huge sheet to build a waterproof tarp to line a pool. To melt different bags into a single sheet of plastic, we employed both hand-held irons and a heat press. We tested various types of plastic bags and discovered that soft and elastic bags easily tore and did not melt well. Plastic bags used for shipping packaging, on the other hand, proved to be the most effective. We were eventually able to make a modest prototype with the tarp lining a bucket of water. It successfully held the water, demonstrating that it was leakproof. Going on, we shall collect plastic shipping bags in order to make a sheet largely formed of that material, which will result in a more seamless sheet.

Sprinkler head

To make a sprinkler head for easier plant watering, we drilled holes in a plastic bottle so the water would spray more strongly. Our experiment worked, but we need to make the holes slightly larger to allow more water to get through and find a way to properly connect the faucet/hose to the bottle. We’ll probably have to use tape to secure it, which won’t be easy to remove or serve as a long-term solution. To make it more long-lasting, we’d have to utilize a screw top on both ends, which would be difficult to build.

Filter Net

We used plastic bags to weave a net to keep leaves, branches, and other debris out of a rainwater collection system. We cut the bags into loops, knotted the loops together, and then crocheted the loops into a braid. We linked many of these braids to make a net that may trap heavier debris. We were able to achieve varying braid thicknesses by cutting the loops into different widths. However, the braids’ varying thickness and tightness made weaving them together problematic. To make assembly easier in the future, we should cut more consistent loops and weave them looser.

Water Tube

We made a tube last week by cutting slots in the bottoms of plastic bottles and interlocking them together. We used a hairdryer on plastic shipping wrapping wrapped around the seam to seal the attachment and make it leakproof. The heat caused the slits in the bottle to distort as the plastic around the bottles shrank to making the attachment more secure. This resulted in sharp edges that sliced into the plastic, causing leaks in the bond. This does not appear to be a viable option because boiling the bottles will twist them into unfavorable shapes. To avoid the heat, we would most likely need to use strong tape.