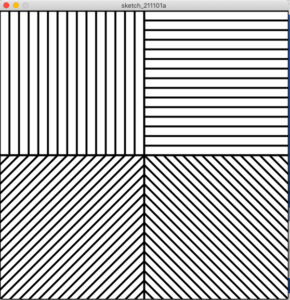

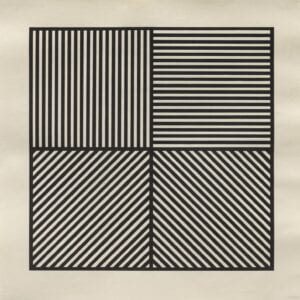

Found this motif by clicking the link on interaction lab recitation website.

Really like the diagram and thought it would be easier to draw on processing by drawing four rectangle and split equally and draw 15 lines in each.

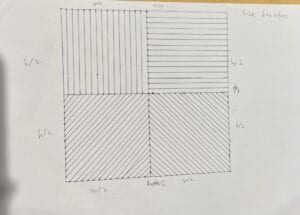

My rough sketch

my code:

int s = 20;

strokeWeight(4);

size(600,600);

rect(0,0, width/2,height/2);

rect(width/2,0, width/2,height/2);

rect(0,height/2, width/2,height/2);

rect(width/2,height/2, width/2,height/2);

line(s,0,s,width/2);

line(s*2,0,s*2,width/2);

line(s*3,0,s*3,width/2);

line(s*4,0,s*4,width/2);

line(s*5,0,s*5,width/2);

line(s*6,0,s*6,width/2);

line(s*7,0,s*7,width/2);

line(s*8,0,s*8,width/2);

line(s*9,0,s*9,width/2);

line(s*10,0,s*10,width/2);

line(s*11,0,s*11,width/2);

line(s*12,0,s*12,width/2);

line(s*13,0,s*13,width/2);

line(s*14,0,s*14,width/2);

line(width/2,s,width,s);

line(width/2,s*2,width,s*2);

line(width/2,s*3,width,s*3);

line(width/2,s*4,width,s*4);

line(width/2,s*5,width,s*5);

line(width/2,s*6,width,s*6);

line(width/2,s*7,width,s*7);

line(width/2,s*8,width,s*8);

line(width/2,s*9,width,s*9);

line(width/2,s*10,width,s*10);

line(width/2,s*11,width,s*11);

line(width/2,s*12,width,s*12);

line(width/2,s*13,width,s*13);

line(width/2,s*14,width,s*14);

line(0,height/2 + s,s,width/2);

line(0,height/2 + s*2,s*2,width/2);

line(0,height/2 + s*3,s*3,width/2);

line(0,height/2 + s*4,s*4,width/2);

line(0,height/2 + s*5,s*5,width/2);

line(0,height/2 + s*6,s*6,width/2);

line(0,height/2 + s*7,s*7,width/2);

line(0,height/2 + s*8,s*8,width/2);

line(0,height/2 + s*9,s*9,width/2);

line(0,height/2 + s*10,s*10,width/2);

line(0,height/2 + s*11,s*11,width/2);

line(0,height/2 + s*12,s*12,width/2);

line(0,height/2 + s*13,s*13,width/2);

line(0,height/2 + s*14,s*14,width/2);

line(0,height/2 + s*15,s*15,width/2);

line(s,height,width/2,height/2 + s);

line(s*2,height,width/2,height/2 + s*2);

line(s*3,height,width/2,height/2 + s*3);

line(s*4,height,width/2,height/2 + s*4);

line(s*5,height,width/2,height/2 + s*5);

line(s*6,height,width/2,height/2 + s*6);

line(s*7,height,width/2,height/2 + s*7);

line(s*8,height,width/2,height/2 + s*8);

line(s*9,height,width/2,height/2 + s*9);

line(s*10,height,width/2,height/2 + s*10);

line(s*11,height,width/2,height/2 + s*11);

line(s*12,height,width/2,height/2 + s*12);

line(s*13,height,width/2,height/2 + s*13);

line(s*14,height,width/2,height/2 + s*14);

line(s*15,height,width/2,height/2 + s*15);

line(width/2,height/2,width, height);

line(width/2+s,height/2,width+s, height);

line(width/2+s*2,height/2,width+s*2, height);

line(width/2+s*3,height/2,width+s*3, height);

line(width/2+s*4,height/2,width+s*4, height);

line(width/2+s*5,height/2,width+s*5, height);

line(width/2+s*6,height/2,width+s*6, height);

line(width/2+s*7,height/2,width+s*7, height);

line(width/2+s*8,height/2,width+s*8, height);

line(width/2+s*9,height/2,width+s*9, height);

line(width/2+s*10,height/2,width+s*10, height);

line(width/2+s*11,height/2,width+s*11, height);

line(width/2+s*12,height/2,width+s*12, height);

line(width/2+s*13,height/2,width+s*13, height);

line(width/2+s*14,height/2,width+s*14, height);

line(width/2+s*15,height/2,width+s*15, height);

line(width/2,height/2 + s, width – s, height);

line(width/2,height/2 + s*2, width – s*2, height);

line(width/2,height/2 + s*3, width – s*3, height);

line(width/2,height/2 + s*4, width – s*4, height);

line(width/2,height/2 + s*5, width – s*5, height);

line(width/2,height/2 + s*6, width – s*6, height);

line(width/2,height/2 + s*7, width – s*7, height);

line(width/2,height/2 + s*8, width – s*8, height);

line(width/2,height/2 + s*9, width – s*9, height);

line(width/2,height/2 + s*10, width – s*10, height);

line(width/2,height/2 + s*11, width – s*11, height);

line(width/2,height/2 + s*12, width – s*12, height);

line(width/2,height/2 + s*13, width – s*13, height);

line(width/2,height/2 + s*14, width – s*14, height);

line(width/2,height/2 + s*15, width – s*15, height);