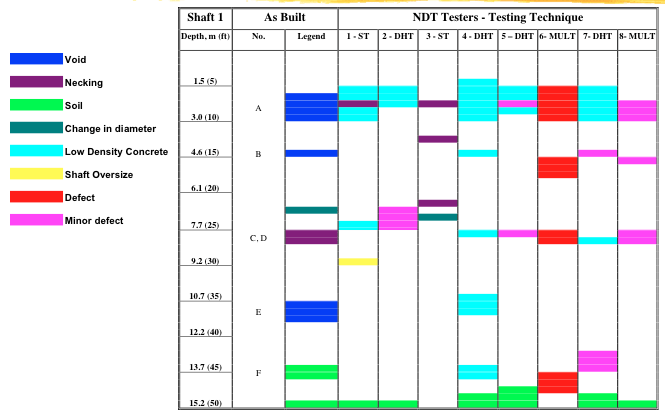

Nine organizations replied to a nationally advertised Class-A defect prediction program; two of these organizations worked as one team. The respondents represented some of the best-known firms and universities in the field. Nondestructive testing predictors were provided with essentially the same site description given in this website and limited shaft construction details. Predictors were invited to test the shafts anytime following completion of construction. Teams 1 – 6 tested Shafts 7 – 21 days following construction, but predictors 7 and 8 tested the shafts several months later. The participants used the following NDT methods:

- Teams 2, 4, 5, and 7 used down-hole techniques including cross hole sonic logging and cross hole tomography;

- Teams 1 and 3 used surface techniques including acoustic wave reflection pulse or sonic echo and impulse response sonic mobility ; and

- Teams 6 and 8 used multiple surface and down-hole techniques.

Summary of NDT Results

Down Hole Methods

|

Surface Methods

|

Shaft 1

Shaft 2

Primary Reference

- Iskander, M., Roy, D., Kelley, S., and Ealy, C. (2003). ”Drilled Shaft Defects: Detection, and Effects on Capacity in Varved Clay.” Journal of Geotechnical and Geoenvironmental Engineeering, 129(12), 1128–1137 [link]