Group Project Planning:

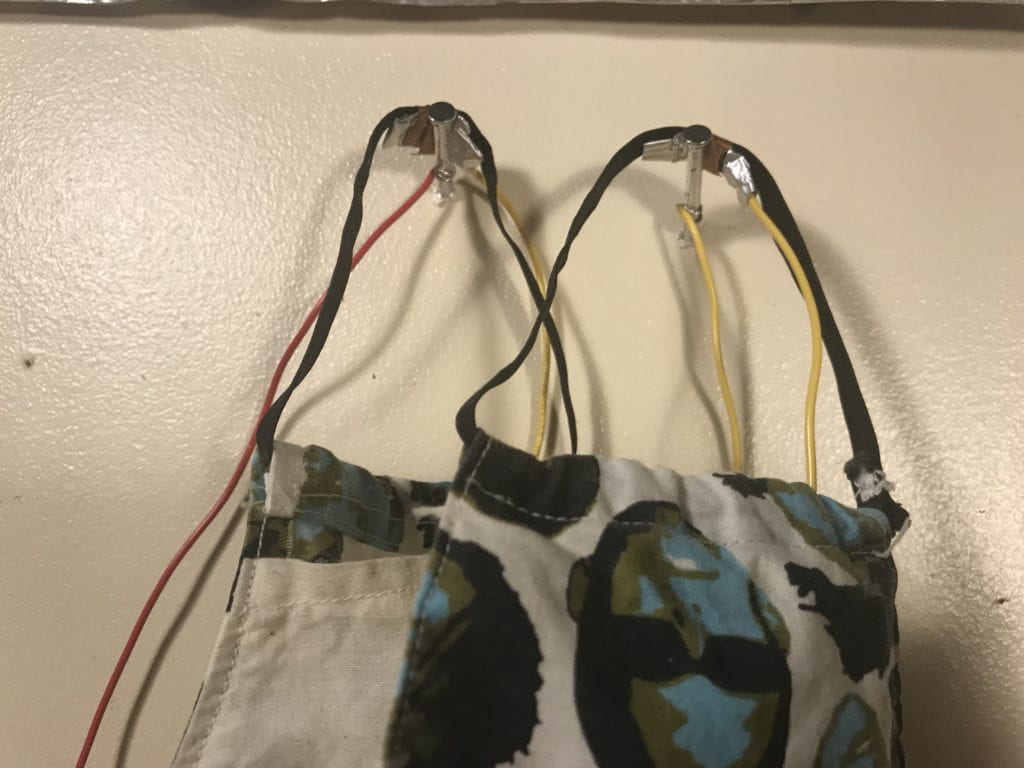

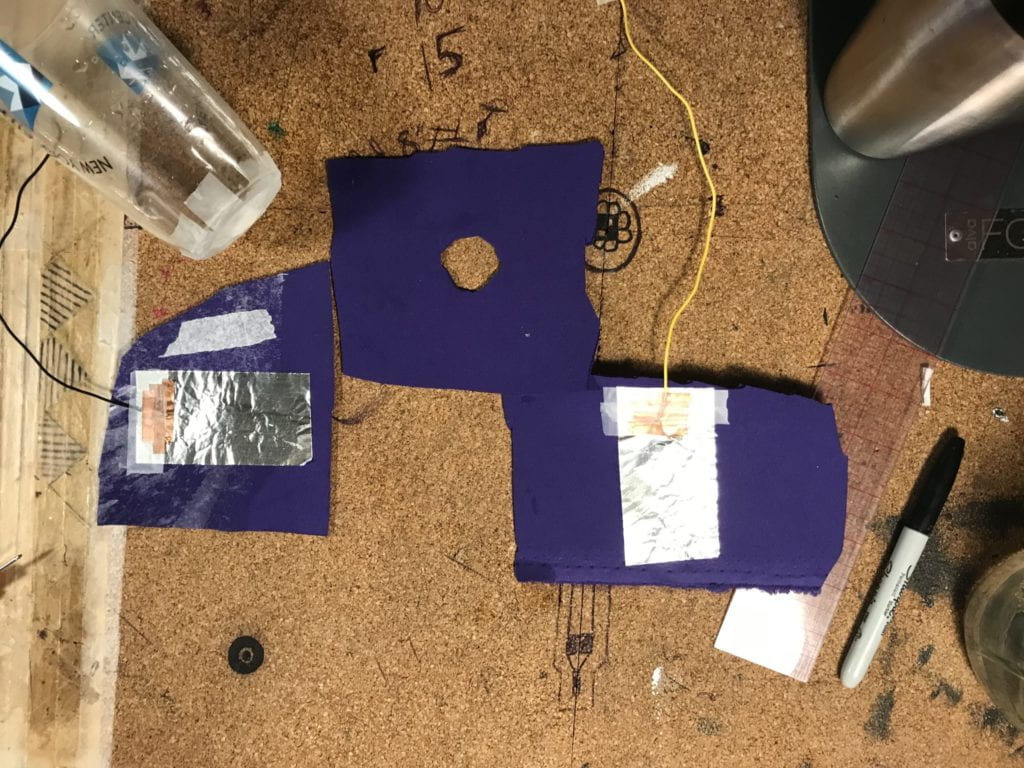

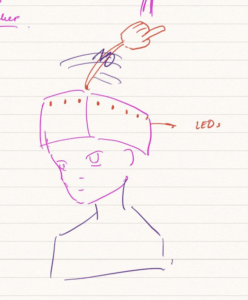

For this week’s group project, I am paired with Yona Ngo and Yonatan Rozin. We were drawn towards building a wearable piece that had a COVID influenced interaction but also something humorous. We decided to make a piece that warned someone when they were too close to the user. Below is our preliminary design for the piece by Yona

The hat will feature a sensor placed in the back of the hat that will trigger LEDs to flash, a finger to wave, and a speaker to create pitches at the intruder. The pitches will be in an ascending pattern in an attempt to mimic someone saying “no, no, no” while wagging a finger. We thought this would be a cute and humorous piece during this stressful time.

Production Plan:

Since we are all in NYC, we will be meeting this weekend/this coming week at 370 Jay Street to build this piece.

We will use the following to produce the piece:

– Ultrasonic Ranger

– LED’s

– Several 220 Ohm resistors

– Servo motor

– 9V DC battery with snap connector

– Arduino

– Cardboard

– Copper tape

– plus other items we are missing…

Questions we will need to answer:

– How far can the ultrasonic ranger pickup distance from? Hopefully 6ft?

– Will be have enough voltage with the 9V to power everything?

-If we are not all able to meet in person due to scheduling, how will we divide up the work?

Labs:

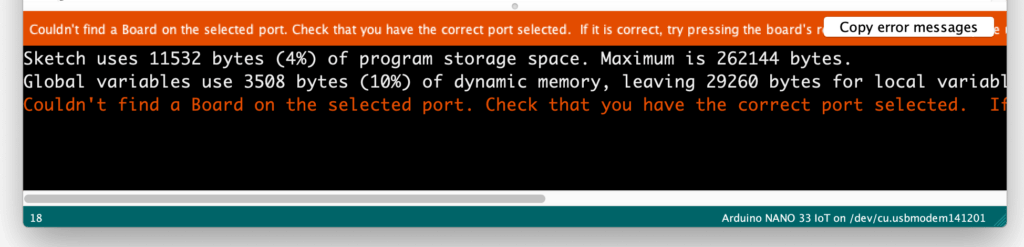

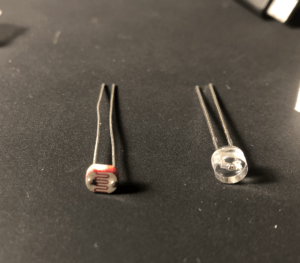

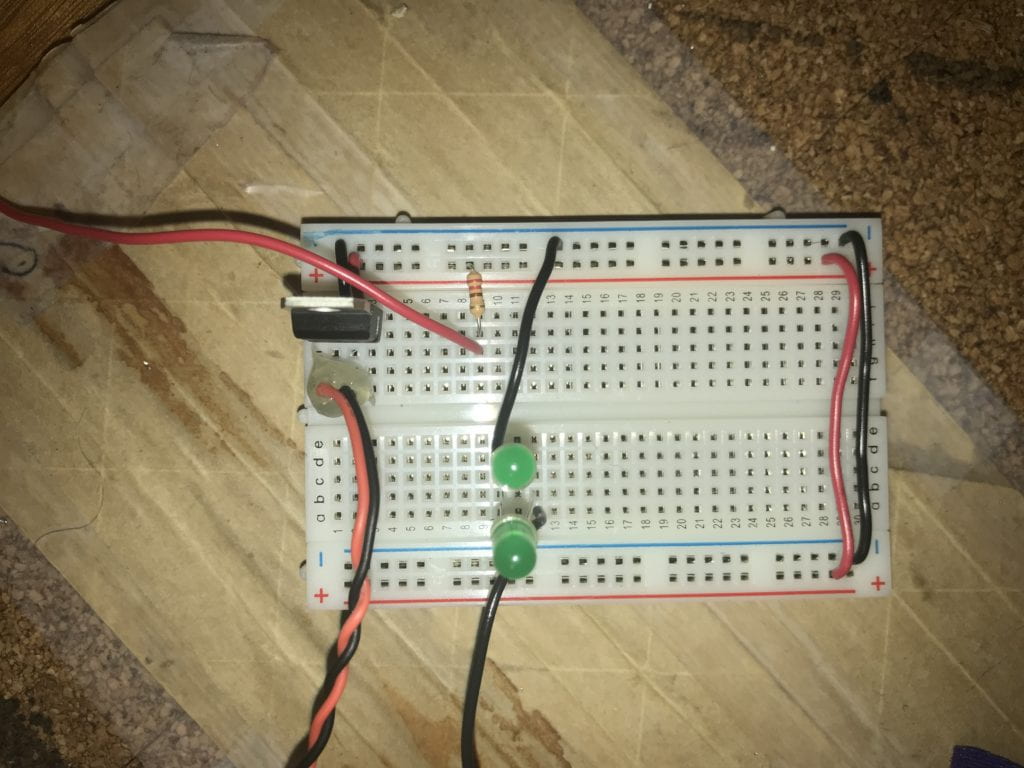

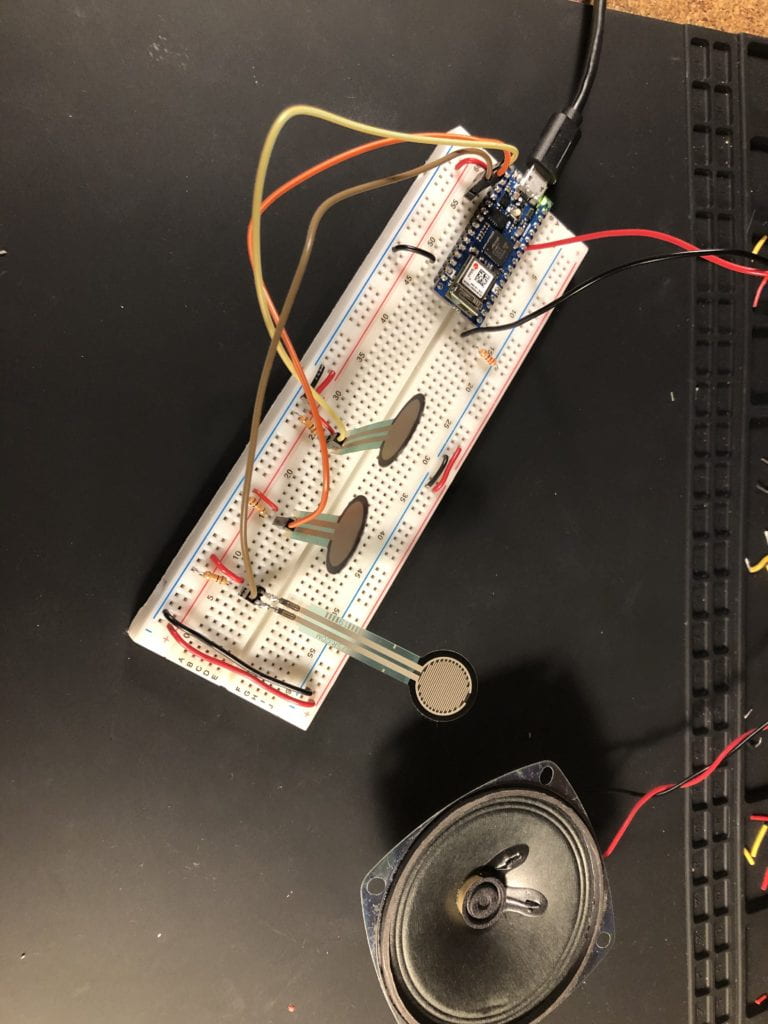

Lab: Tone Output Using An Arduino

When I started this lab, I had a few initial questions. I wanted to add wires or headers to the ends of the FSR but I could not locate the videos Tom Igoe posted where he demonstrated how to do that. I decided top ake a stab at it myself which was mostly successful. Also, I did not have the necessary 100 Ohm resister or this project. I’m not sure exactly how it effected the lab but I did have issues. Since I didn’t have a 100 ohm resister I used the closest one i had, a 220 Ohm.

I setup the boards and uploaded the program but was not able to get any reaction out o the 2nd FSR. Is it supposed to have impact on the tone?

Musical Tones:

Got the music to play!

Last one:

Got the setup right but still with the 220 ohm resister instead of the 100 ohm connecting the speaker to ground. I had a similar issue as with the first lab. Only the second sensor was able to get a noise to play.

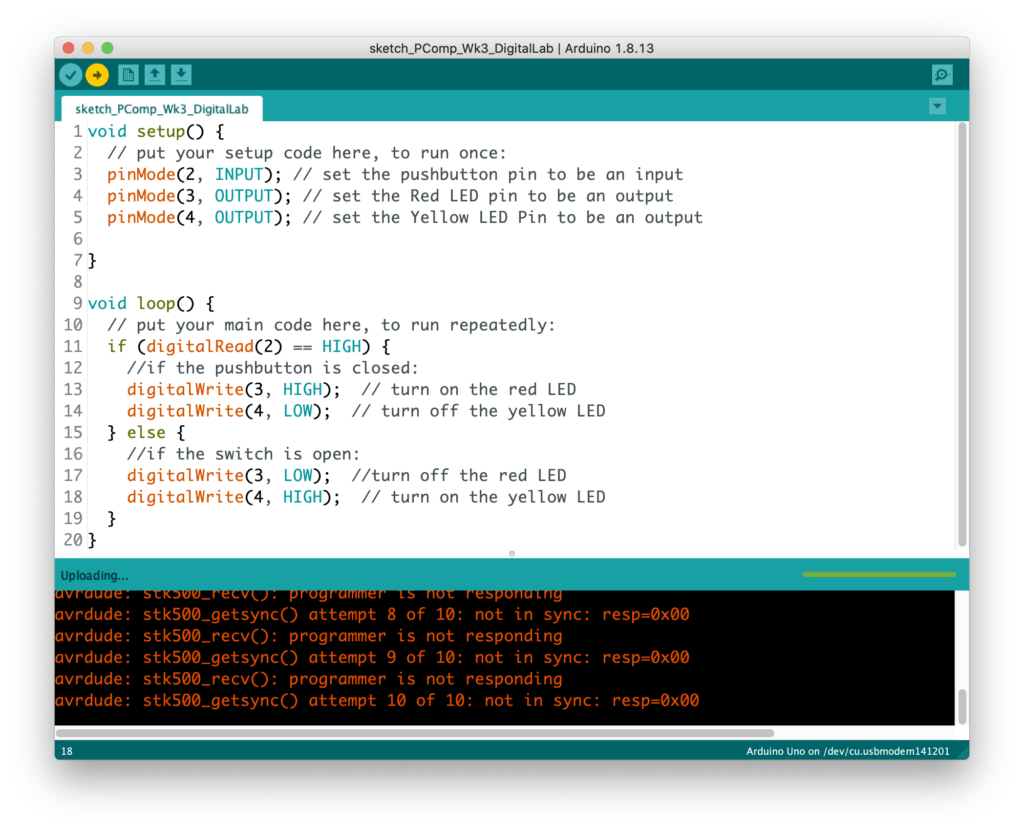

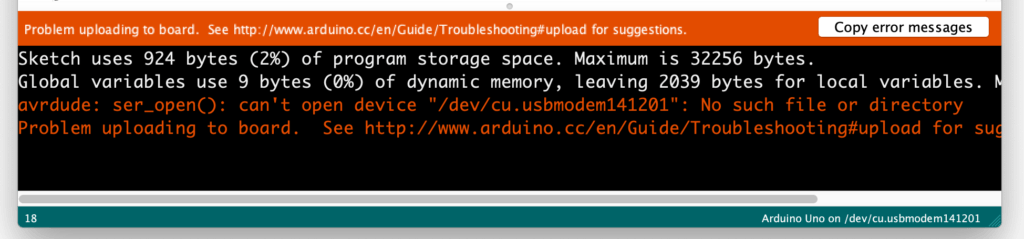

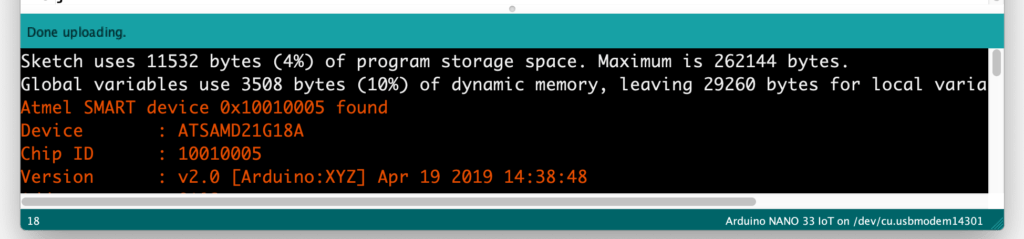

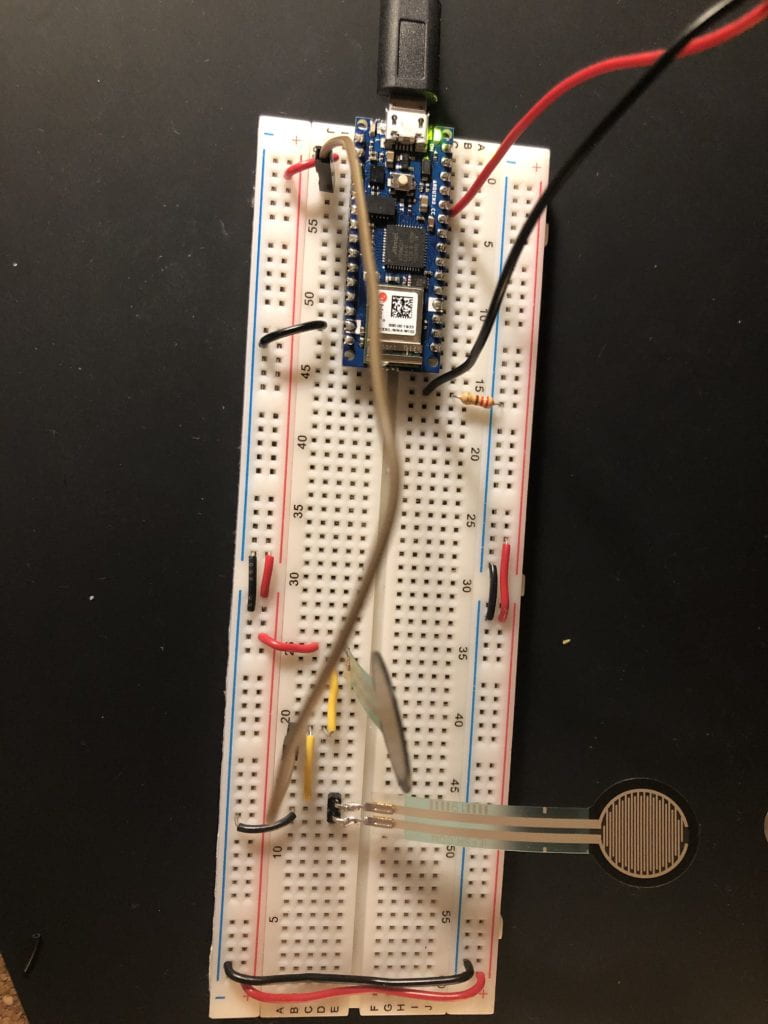

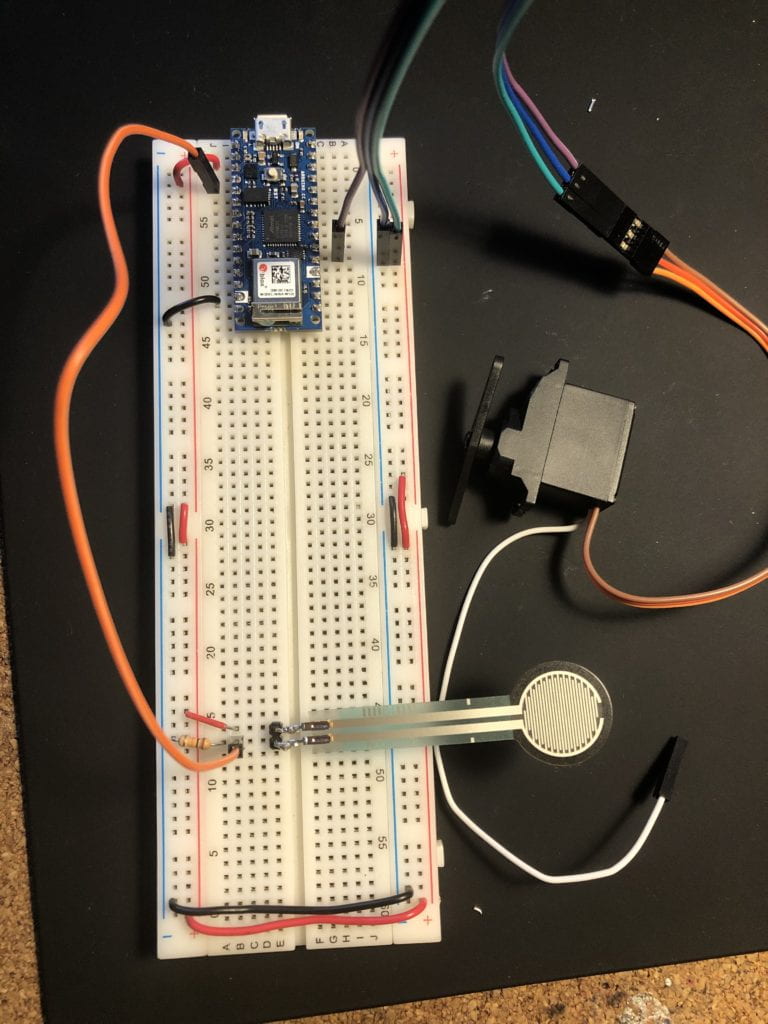

Lab: Servo Motor Control with an Arduino

To start, I pulled out the pieces I needed and noticed something odd with my servo motor, it had a 4th wire. I have an Analog feedback Micro servo motor S1123 from Adafruit. Per their site, the additional wire is “the feedback (potentiometer wiper) line is brought out to a fourth white wire. You can read this wire with an analog input such as those on an Arduino, to get the servo’s position. “ That answer that question but how do I figure out which of the other 3 wires goes where. The wires are Brown, orange and a yellow/orange. None of which follow the color scheme I am familiar with. in order to figure out which was ground and which was power, I watched the video on Adafruit’s site. Unfortunately, I think my guess was incorrect as you will see in a moment.

When I setup the breadboard originally, the FSR was not reading. Instead o testing the wiring, I decided to try a different component as I was concerned the FSR was not working properly. That switch created the same result, nothing. Next I took a look at the wiring and there was the culprit; I had the wire from GND of the FSR going into the wrong pin of the Nano. Once corrected, I tested the output of both the potentioneter and the FSR successfully. Next came programming for the motor and testing.

I was able to get the code setup as needed with very little challenges. The challenge I had was getting the motor to work. I went with my initial wiring configuration guess, then tried a few others and still nothing. I decided it was time to call is a night and schedule some time for additional help with these assignments.