State of the Mass Timber Industry

Over the month of March, an organization called Mass Timber City held a series of webinars entitled Mass Timber March Madness (henceforth, MTMM). Speakers came from all over the world, including mass timber hotspots like Finland and Germany, as well as those working in the more nascent industries in the United States and Canada (a full list of speakers can be found here). They came from many industries, including mass timber production, general contracting, architecture, government, sustainable finance, and tech, which has embraced mass timber much more rapidly than the broader American market. Notably, there was not a substantial presence from real estate developers. Through the month of discussions, a broad narrative emerged. Participants saw the mass timber industry as poised for substantial growth, and with the potential to play an important role in the fight against climate change and the housing crisis. However, scores of obstacles, from regulatory hurdles and exclusionary zoning to engrained workflows in architecture to developer and financier wariness remain to be solved. These problems are complex and interconnected, and the solutions are far from clear, but they also present opportunities for the entrepreneurially minded.

What is Mass Timber? Why is this an Exciting Opportunity?

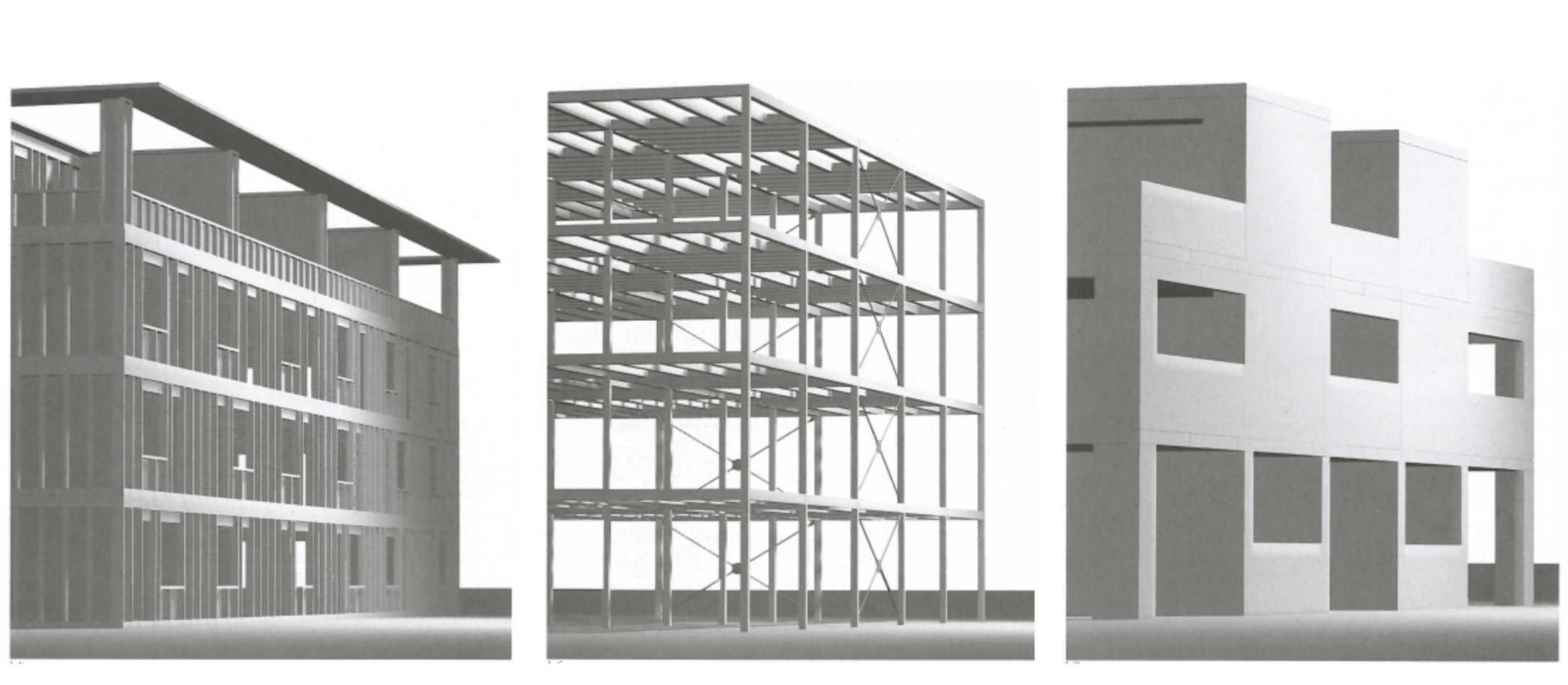

First, it might be useful to provide some background on Mass timber, and why many find it so exciting. Mass timber refers to a wide swath of products that usually amount to a great deal of small pieces of wood combined into a much larger piece. The size of the smaller pieces and the method of combination can vary, and each technology has advantages and disadvantages. The most well-known in the US is probably CLT, or cross-laminated timber. CLT is made up of timber boards (often pretty similar to the 2” x 6”s found at a typical hardware store) glued into panels edge to edge. These panels are then glued face to face with the direction of the boards alternating (cross-laminated). These panels can be used for floors, walls, and roofs. Panels are also made of boards nailed together (NLT, or nail laminated timber) and held together by dowels (unsurprisingly, DLT, or dowel laminated timber). Structural beams are often made of Glulam, which like CLT is made up of boards glued together, but rather than gluing edge to edge first, Glulam is typically a single board width, but can be made very deep.

Besides these and a variety of other similarly comprised products, there also exist more elaborate and technical mass timber products, like prefabricated floor systems that use structural engineering to decrease the amount of material compared to CLT. This has the added benefit of providing ready space for things like insulation and mechanicals as well (which can even be installed in advance!).

With that far from comprehensive overview complete, why are people excited about mass timber? There are a few answers, but the most important is that mass timber is generally considered an environmentally friendly alternative to typical steel and concrete tower construction. While details of construction technique will affect this number, building a mass timber tower typically produces somewhere around 20% of the emissions of a similar tower in steel and concrete (although there is debate around this number). Additionally, trees absorb carbon when they grow, and store it until the tree is burnt or dies and decays. When a tree is made into timber and then into a building, that carbon is “captured.” When paired with sustainable forestry practices, mass timber buildings have the potential to act as a massive carbon sink – one of the best possibilities at present to not just slow climate change but reverse it.

Despite the purported benefits of wood construction, many people’s reaction is simple – what about fire? The answer is that these mass timber buildings do not burn in the way wood typically does, say in the way that a standard stick frame American home burns. While part of this is due to a variety of technological safeguards, like fire-resistant coatings and powerful sprinkler systems, much of it comes down to the simple bulk of mass timber products. When a mass timber beam burns, the exterior chars quickly. However, it is difficult for the fire to move deeper into the beam, because there isn’t sufficient oxygen to fuel the fire. While it can burn eventually, mass timber can achieve similar fire safety to other construction methods.

Mass Timber in the United States Today

Mass timber construction has a long history in the United States, going back to heavy timber framing that, rather than using many wood boards glued together, simply used massive old-growth trees to provide similarly massive beams. Many of these buildings survive, often in the form of warehouses in older cities. However, fire in Chicago and San Francisco (which loom large in any discussion of mass timber) changed the perception of wood construction in the US, and steel and concrete became universally dominant. While this began to change in Europe several decades ago, the United States has moved much more slowly. One frequent lament from event commentators was how much the US lags Europe in terms of supplier and product volume and diversity, as well as in completed projects. That said, projects are happening. Much of the activity is centered on the west coast, where the timber industry is long established. The current tallest mass timber building in the US is the eight story Carbon12 in Portland. In New York, there are a few mass timber office projects under construction, and there were plans for a 10-story condo building on 18th Street (designed by SHOP architects, which is active in the space), but this ended up falling through.

Despite this lag, the United States does appear to be picking up the pace. The number of projects tracked by industry group Woodworks has increased substantially over the last decade. Hundegger, a prominent manufacturer of the CNC machines used to manufacture many mass timber products reported increased interest and sales of their machines to the United States. One strong market for mass timber buildings has been the offices of high-tech firms. Representatives from both Sidewalk Labs (an Alphabet company) and Microsoft presented during the event, and both firms are investing both in mass timber and in the technology that supports it. Even outside tech, mass timber offices appear to be settling in as an attractive and visible way for a firm to demonstrate its social conscience. Wal-Mart has announced that its new Arkansas campus will be primarily mass timber – more than 1.1 million cubic feet. As further demonstration of their interest, the firm also invested in Structurlam, the company that will produce the components for the project. There is also increased interest from the finance sector, both in the form of ESG (environmental, social, and corporate governance) focused funds and on venture capital in general, which, as readers of this magazine will know, view proptech and contech as large potential markets.

Obstacles to Broader Mass Timber Adoption

Despite these positive trends, there remain substantial obstacles to widespread adoption of mass timber.

Regulatory Hurdles

One of the most substantial is building code and local regulatory bodies, who have moved much slower than their European counterparts in supporting mass timber. The International Building Code, on which most American building codes are based, permitted wood-frame structures up to six stories (85 feet tall) in 2012. The newest edition, the 2021 IBC, allows for mass timber up to 18 stories (270 feet) and nearly one million square feet. This is slow, by international standards. In Canada, the student housing tower Brock Commons opened in 2017 with a height of 18 stories (174 feet). Mjøstårnet in Norway opened in March of 2019, at 18 stories (280 feet). Furthermore, the IBC requires mass timber buildings at that height be fully encapsulated in drywall, which adds cost and removes the aesthetic advantage of wood construction. Finally, some American jurisdictions move even slower than the IBC – New York’s upcoming code revisions are based on the 2015 and 2018 IBC, which means they will not include the taller mass timber allowances. While it is still possible to build mass timber towers where they are not explicitly allowed by code, this requires expensive ad-hoc performance testing, which adds substantial complication to an already complicated choice for developers.

That said, regulation does appear to be moving in the right direction for mass timber, and there are organizations tackling the problem from a variety of directions. Proponents of mass timber have been involved in drafting the IBC’s new rules. Trade organizations like Woodworks (a MTMM attendee) are advocating for these changes and educating the development industry on their progress. From another direction, Jon Roebuck of Holmes Solutions spoke of how his firm provides testing of materials, components, and designs for developers to demonstrate safety to local regulators. This helps developers establish “performance-based” code compliance and is the method by which existing or in-progress mass timber buildings in NYC have been permitted. It’s a helpful option for those looking to pioneer, but the added time, expense, and uncertainty hinder widespread adoption. Roebuck highlighted the need to move from a “detail” to a “product” – that is, from a one-off solution that solves a problem to a plug-and-play, tested solution with regulatory approval that can be deployed repeatedly.

Insurability

Another complication for mass timber construction is insurability. While the safety of well-engineered mass timber construction has been firmly established, its novelty and the slow movement in building codes makes it a more difficult sell to insurers. According to Janelle Leafblad of Woodworks, it is frequently a challenge for owners to get their insurers on board with a mass timber project. Woodworks can help walk owners through that conversation and provide useful data, but like most problems emerging from mass timber’s novelty, increased exposure may be the most potent cure.

Trained Labor Availability

While a frequently mentioned benefit of mass timber construction is the potential for smaller construction teams (particularly valuable given the large and growing labor shortage), specialized skills are required. Many contractors are not familiar with mass timber construction and so may be wary of taking on a project. Similarly, developers may have difficulty finding an experienced mass timber team, which further increases perceived risk. Leafblad again highlighted Woodworks’ work in this area, which includes training seminars where construction workers get hands-on experience with mass timber, including life-sized joint assembly. Increased interest in mass timber construction should lead to more labor acquiring the skillset, and each additional project means more seasoned workers.

Developer Wariness

Perhaps understandably, given these challenges, developers and financiers have been hesitant to move into mass timber. Many of the benefits of mass timber construction, from its sustainability to shorter construction timeframes and lower finishing costs, are difficult for developers to quantify. Some of this is a data issue, and organizations like Woodworks are working to solve it (for instance, by publishing case studies). Policy makers have ample opportunity to encourage mass timber, and it dovetails nicely with many cities’ stated goals around climate change. However, examples to date have been relatively sparse. For example, NYC’s widely heralded Local Law 97 is concerned only with operational carbon, not embodied carbon, drastically limiting mass timber’s value.

Mass Timber & PropTech

Another notable theme of MTMM was the intersection of mass timber and construction and proptech. Because substantially more work on a mass timber building is done off-site, the process lends itself quite naturally to many technological and process advancements. Offsite manufacturing is one of these, and presenters noted numerous advantages. Building in a factory allows the environment to be sculpted around the work required – it removes weather from the equation, improves safety, and typically allows for more precise work. Construction in urban environments typically involves small nuisances for neighbors, like noise and road closures. More work done offsite means less of these annoyances, which could help diminish anti-development sentiment. Additionally, taking the work offsite allows for the simpler utilization of impressive new machinery – massive CNC machines and robotics capable of ever more complex work. .

BIM & DfMA

However, the more parts arrive at the job site finished, the less room there is for improvisation. This means that more care must be taken in the design, and fewer problems can be left half-solved, for completion on the job site. The industry is already moving in this direction, and BIM (Building Information Modeling) products continue to get more sophisticated. Where CAD (computer-aided design) allowed construction drawings to be done digitally (and hence, much more quickly and easily), BIM allows practitioners to model the connections and performance that emerge out of those drawings.

However, MTMM presenters highlighted several areas where the process needs improvement. Perhaps the most straightforward representation of the problem came from Fabian Scheurer of Design to Production, a firm that helps shape designs towards manufacturability – “when you digitize a shitty process, what you get is a shitty digital process.” Each participant in the design process – architects, engineers, general contractors, subcontractors – is siloed during the design process, and information flows primarily in one direction (down, from engineer to architect to contractors to suppliers). Substantial technical knowledge is required at each stage, but good processes for sharing that information are uncommon or nonexistent. Scheurer noted the waste involved in a typical design process, where each actor provides too much information and too little quality (architects draw details subcontractors will glance at, and then begin from scratch). Salla Eckhardt of Microsoft said that her firm’s first focus is on simply establishing data standards so that information can be effectively passed between designers, producers, contractors, and operators. If information can be made to flow both directions more efficiently – if general contractors can explain the cost differences between details to architects during the design process, for instance – this could create substantial savings.

This idealized, more communicative process is typically referred to as DfMA (Design for Manufacture and Assembly). This means design that accounts for not only how the building will perform, but also the capacity of producers and assemblers. For example, a BIM model of a mass timber building would incorporate how the various CAD plans fit together, as well as systems like HVAC and electrical. To this, effective DfMA would add the mass timber factories’ production capacities, and assemblage constraints (like whether components interfere with each other’s installation – beams that must be installed first, but prevent CLT floor panels from being craned in, for instance). Wolfgang Piatke of Hundegger, one of the largest manufacturers of the CNC machines, emphasized the importance of understanding the machines capabilities – 95% of operations are easy, 3% are very difficult, and 2% must be done manually. This knowledge exists in the hands of manufacturers and contractors, but there is not a good system to pass it up the chain and allow it to be acted on. If a design is completed without giving thought to these limitations, costs may be substantially higher due to decisions that are not vital to the design intent.

Conclusion

This overview has only scratched the surface of the discussions held over the course of Mass Timber March Madness. For those interested in the industry, videos of the presentations are available on YouTube. Mass timber sits at the intersection of two of the greatest challenges facing the United States – the climate and housing crises. It is also intimately linked with problems facing the construction industry at large, like declining labor productivity. The event organizers should be congratulated for creating an engaging forum for discussion and a valuable learning resource, particularly for budding real estate professionals.

About the author: Aaron Marx is a graduate student at NYU SPS Schack Institute of Real Estate, pursuing a Master’s in Real Estate Development. Aaron is passionate about well-designed, sustainable housing, and obsessed with the policies and technologies that can help produce it.