Introduction

Mass timber, also known as engineered wood, is a composite material manufactured in factories and used for building construction at a variety of scales. Mass timber products are engineered to precise design specifications from home construction to commercial construction to industrial facilities. Use of mass timber could substitute the use of steel in construction and has the potential to turn the built environment into a carbon sink, combating climate change. However, the public image of this material is not as sound as it should be, for a variety of reasons.

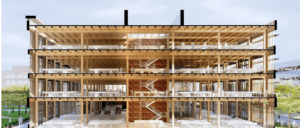

Mass Timber – A Fire-proof, Durable, Light-weight, Sustainable, and Available Material

Is It Safe? Doesn’t It BURN?

Perhaps the most common misunderstanding of mass timber is that it sounds dangerously combustible – especially compared with concrete and steel we see in most of the construction sites today. Many great cities in the US – San Francisco, Chicago, New York – have horrible memories about fire taking lives and bringing whole neighborhoods down. However, mass timber is different from the old dimensional lumbers we used for suburban houses. Dimensional lumbers, such as 2×4 and 2×8, were used in cities for housing and commercial constructions – most low-rise buildings were built in balloon frames and platform frames, and even today most suburban homes are still built in the same manner. By the end of the 19th century, Andrew Carnegie led the revolution of America’s steel industry and popularized the use of steel in construction. Carnegie did such a great job (too great, in a way) that people still believe steel is an excellent fire-proof material.

In one sentence, mass timber is less fire-proof than concrete but has better fire resistance than steel in general. In fact, the steel itself is horrible at fire-proofing – under high temperature it deforms and gives out its structural capabilities quickly, even though it does not burn. Mass timber, however, due to its large cross-sectional dimensions, would char its outside and slow down the burning process significantly. Of course, eventually, it would burn out, but the structure would preserve enough strength to give everyone enough time to get out of the building before the whole building collapses.

The fire-proofing capabilities of mass timber could be enhanced with the use of sprinkler systems. The International Building Code (IBC) has specific fire sprinkler requirements for every construction type and occupancy group. Depending on the material and use purpose of the building, fire sprinklers may or may not be used according to the corresponding IBC excerpt. However, for most sensitive use groups, such as schools or libraries, sprinklers are usually installed to go beyond the code requirements.

Why Is It Sustainable?

Another misconception is that mass timber buildings are made out of large pieces of wood, so we will need to cut down large trees to salvage the material, further hurting the environment. Remember, mass timber elements are engineered and produced in factories from small pieces of wood that are laminated into large components. If we think about how a gigantic steel girder is made – mining rocks that contain iron, melting it under thousands of degrees to isolate the useful components from the rest, adding in carbon and other ingredients, forming it under high pressure – a process which does not produce less carbon footprint than a factory cutting and gluing wood pieces together- it is obvious why mass timber production is greener. And concrete not only requires steel rebar reinforcement, its most important component – Portland cement – has one of the highest carbon footprints among all building materials.

Admittedly, the overall level of sustainability of a building project is a result of its location, mechanical equipment, material selection, and many other attributes, but mass timber could offset the carbon footprint largely from the construction aspect.

The Pros and Cons of Mass Timber, and How It Is Changing

Quick and Quiet Construction Sites, Financial and Labor Union Considerations, Limitations in the Long Term, and AESTHETICS

If you visit a mass timber construction site, you will not see smokey sparkles or smell rusty fumes from cutting and welding steel pieces together. You will also very likely see much smaller cranes and other equipment and suffer from much less noise than on a steel and concrete job site. Because it is also a much lighter material to handle, the speed of mass timber construction generally exceeds the speed of steel and concrete projects, even when the subcontractors have never used mass timber before. Mass timber buildings are roughly 25% faster to construct than concrete buildings and require 90% less construction traffic (Think Wood).

Besides the cost-saving as a result of faster construction, the cost of the material itself is going down as the use is scaling up. Although at the current moment mass timber is not universally cheaper than steel and concrete, in places like NYC it is actually more economical to build with mass timber with proper pre-fabrication processes. WoodWorks, a non-profit organization focusing on promoting mass timber construction, together with many other peer organizations, are training unionized construction workers to get familiar with this old but new material, easing the path for real-life applications.

Although mass timber is quite a versatile material, it is not for every project type. Currently, the tallest mass timber buildings are all around 20-stories tall, and most mass timber buildings are “flatter.” As building codes and construction techniques continue to keep up with the development of this material, mass timber buildings will likely be built taller, but it is unlikely that we will have a 100-story mass timber in the near future.

Last but not least, mass timber buildings are architecturally appealing. People like the warmth and texture of wood and built mass timber buildings are described as brighter, healthier, and more aesthetically pleasing. For office buildings, mass timber buildings are reportedly costing the landlord less in tenant improvements than a conventional steel and concrete building because the tenants enjoy the exposed wood structure.

Recent Mass Timber Projects in the US and Canada

John W. Olver Design Building at UMass Amherst

Amherst, MA

Leave a Reply