The Cozy Bleats – Weekly Updates

On this page

- Update 1: Project Goals

- Update 2: Competitive Analysis

- Update 3: Material Review and Rapid Prototyping

- Update 4: More Rapid Prototyping with Trampoline Mesh

- Update 5: Rapid Prototyping Mesh Attachments

- Update 6: Confirmed Build Materials

- Update 7: Instructional Guide

- Update 8: Build Process

- Update 9: Final Presentation and Next Steps

- Update 10: More Instructional Materials

Weekly Update 10: 12/17/22

After our final presentation on Tuesday, we reinforced the screws on our current prototype of Fin’s crib. We swapped out around ten of the smaller screws for M3, 2″ longer ones, which were mostly placed near the PVC pipe fittings. All the screws were reinforced with washers and locking nuts. Our professor, Anita, plans to bring this modified prototype to Goats of Anarchy, so they can re-evaluate it.

Additionally, we filmed a video for Goats of Anarchy, where we explain the build process of our current prototype. This video includes a walkthrough of the formulas involved in calculating the dimensions and amounts of materials needed for any given bed. Furthermore, we updated our instructional guide to reflect the appropriate measurements, which we learned in our own build process.

The links to our guide and second video can be found on our landing page.

Weekly Update 9: 12/13/22

This week, we worked on our final presentation, finalized a plan for our modified prototype, and updated our written instructional guide.

Our final presentation, which can be viewed online, details our process from the beginning of the semester. We briefly go over our project goals and design challenge, as well as the competitive analysis we conducted for the mesh and mesh-to-frame attachments. We spend more time detailing our build process, which we did at the ITP Makerspace at NYU Tandon and the Goats of Anarchy’s farm.

In our final presentation, we included two competitive analysis charts to summarize the various mesh and mesh-to-PVC attachment methods we researched. The cost columns range from a single ‘$’ (relatively cheap) to four ‘$$$$’ (very expensive).

The following competitive analysis chart details the effectiveness of different meshes:

| Resilience | Drainage | Comfort | Lightweight | Cost | |

| Cat litter mat | No | Yes | Yes | Yes | $$ |

| Rubber floor mat with connectors | No | Yes | Unsure | Unsure | $$ |

| TPE gel mattress | Yes | Unsure | Yes | No | $$$$ |

| Silicone rubber sheet without holes | No | Yes | No | Yes | $ |

| Nylon mesh | Unsure | Yes | No | Yes | $ |

| Sports netting | Yes | Yes | Unsure | Yes | $$$$ |

| Crinoline | Unsure | Yes | No | Yes | $ |

| 3D prints | Unsure | Yes | Yes | Yes | $$$$ |

| Trampoline mesh | Yes | Yes | Yes | Yes | $$$ |

The following competitive analysis chart details the effectiveness of different mesh-to-PVC-pipe attachments:

| Resilience | Secure | Protective | Time Efficiency | |

| Zip ties | Yes | No | No | Yes |

| Rivets/eyelets | Unsure | Unsure | Yes | Yes |

| Rope | No | Unsure | No | No |

| Sewing | Unsure | Yes | Yes | No |

| Drilling + screws | Yes | Yes | Yes | Yes |

We realized that our current prototype isn’t ready to test with Fin. In an ideal world, we would make the PVC frame wider, replace the current screws with 1.5″ screws fortified with bolts and washers, and wrap an additional 3″ trampoline mesh on each side to deepen the central dip. We can’t achieve all of these steps with the resources we currently have. However, we can anticipate the extra trampoline mesh being a success after making the current prototype skinnier to accommodate extra mesh from both sides.

We’re still unsure if longer screws are necessarily better than the shorter screws we’re currently using. Adding washers and bolts would definitely make the attachment more secure, but we’re still worried if longer screws will risk the PVC pipes cracking, since they’ll already be bearing Fin’s weight for multiple hours at a time. We realized the 2″ screws would meet the outer diameter of our PVC pipes exactly, so we can’t use 2″ screws. Anything longer seemed unnecessary to Allison and us. So, we decided to go with 1.5″ screws as a good compromise.

We plan to keep our prototype a slightly skinnier width, since Allison thinks Fin would still fit inside. The dip that we see with this current prototype is roughly 1″ extra mesh on each side. On Wednesday after finals, we’ll swap the screws out and add the fortifications. Moreover, we plan to record a video showcasing our build and walking through the step-by-step process of this specific build. The caretakers at Goats of Anarchy could then decide if they’d like to test with our modified prototype, or if they’d prefer to build a new one with our additional recommendations.

Lastly, we updated our written instructional guide to include these new modifications. We plan to update the photographs with those of the modified prototype when we film our video on Wednesday.

The Cozy Bleats had such a fun and rewarding time learning about unique materials and constructing the prototypes. We really hope that Fin finds comfort in the final version of this bed. Hopefully, other sanctuaries will be able to replicate this build to their animals’ needs!

Weekly Update 8: 12/6/22: Build Process

|

|

|

|

|

|

|

|

Build at NYU

This week, we built a larger prototype of Fin’s crib at NYU and GOA’s farm.

We first built out the full prototype at the ITP Makerspace. To start, we recreated the cuboid frame with PVC tubes at roughly 49″ x 32″ x 12″. The PVC pipes we purchased from Home Depot need to be cut, since they only sell pipes at fixed lengths. To secure the top frame to the bottom four legs, we used four PVC pipe connectors.

Next, we began prepping the trampoline mesh. To allow for some give on the two sides of the mesh, we added eight inches to the original PVC top frame dimensions, bringing the cut-out to 56″ x 40″. We cut the longer mesh to these dimensions and laid it out on the top frame.

Once the mesh looked centered, we began marking the four edges of the top PVC frame. These markings would be where we would drill holes into the tube to secure the mesh with screws. We found that drilling holes roughly 5″ apart did the trick. We also found that aligned drill markings helped with keeping the mesh’s “center of gravity.”

After we realigned the mesh along the drill hole markings, we drilled the screws in. We used 2.8mm screws with a 3.18mm drill bit, since the screw head was just small enough to fit the size of the trampoline mesh’s holes.

The trampoline mesh bunched a bit around the corners, but we decided not to cut it for two reasons:

- We didn’t want to risk creating gaps where Fin’s hooves could get caught (this would be very dangerous)

- We wanted to preserve the mesh in case this model didn’t work, so the GOA caretakers could reuse it for a different model

After double checking the tightness of the PVC connectors and mesh securement, we gave it a try. Simone and Maggie sat on the crib and found it to be quite comfortable. The mesh dips under their weight, which is ideal for Fin, so he doesn’t accidentally roll off. However, we did notice that the long PVC pipe edges bent a bit. We think this is because we weigh more than Fin, who is around 72 pounds. We also think that adding T-shaped PVC connectors at the center of the long edges would better stabilize under weight.

Build at GOA

We drove out to New Jersey on a sunny Sunday and were excited to meet our professor, Anita, there!

When we arrived at GOA, we took a look at their latest build for Fin’s crib. They used the same cuboid PVC frame. For the mesh, they used two layers that included golf sports netting. We were excited to see the sports netting working well, since that was something we had considered in our competitive analysis.

We also got to meet Allison, who’s the project manager at GOA and a lead in constructing the goats’ cribs. We worked together to reassess our current build plan. Together, we realized that three additional adjustments would be ideal for the final product:

- Utilize screws that go all the way through the PVC pipes, fastened with a lock bolt system and washers

- Add 3″ to 4″ to the sides of the trampoline mesh and have the loose ends wrap around the PVC pipes

- Widen the frame just a bit so Fin can be more comfortable

We decided to attempt some of these adjustments with our remaining materials back at NYU. Between now and our final next Tuesday, we can feasibly swap out the current screws with longer ones, while also fastening them with washers and a bolt system. Unfortunately, we can only work with 1″ give from both sides of the mesh, as it was already cut into halves for a single crib. After discussing with Allison, we think the 1″ give could potentially work, though ideally it would be around 3″ to 4″. The GOA caretakers could also make the PVC frame a bit wider for Fin, but it may not be necessary, because he tends to curl up in the center of the crib.

We learned so much from these two build processes! We’re excited to consolidate our findings into a revised instructional guide that the GOA caretakers (and hopefully others!) can use.

Weekly Update 7: 11/29/22: Instructional Guide

While we waited for our full trampoline mesh to ship, we decided to work on a written instructional guide for animal caretakers to have access to. We used our smaller prototype as the reference, but we provide formulas for custom dimensions, depending on the size of the goat. Please read the PDF below for specific instructions.

11292022_Instructional_Guide_Constructing_PVC_Trampoline_Mesh_Beds_Disabled_Goats

Weekly Update 6: 11/22/22: Confirmed Build Materials

After reviewing our smaller prototypes, we believe we’re ready to build a larger crib for Finn. We’re super grateful to Leanne and GOA for agreeing to cover material costs, like the trampoline mesh from Sailrite.

We would need the following materials to construct Fin’s bed:

- 1-2 yards of trampoline mesh (per bed, just 1 for Fin)

- PVC tubes and corner pieces

- 2.38mm screws

- Drill

We’re currently waiting for the trampoline mesh to be shipped to NYU. We’ve decided to build on campus, in case we find ourselves needing additional tools nearby. We’d also like to test the frame with people first before having Fin lie on it. Once the build is complete, we plan to visit GOA with the bed. We’ll bring tools with us to make additional adjustments as needed.

Weekly Update 5: 11/15/22: Rapid Prototyping Mesh Attachments

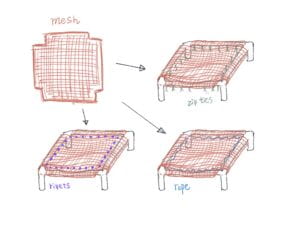

This week, we focused on securing the trampoline mesh onto the PVC pipe frame. We built a few cheap and rapid prototypes to get a sense of what alternatives exist beyond zip tying the sheets on, since zip ties move the mesh around under pressure and could run the risk of cutting into Fin’s skin.

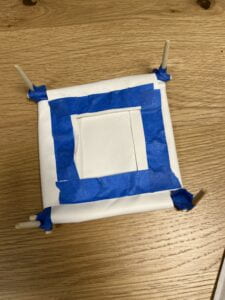

Wires and Tape

For this rapid prototype, we ran wires through an alternative canvas-like fabric, mimicking a sewing technique. Then underneath, we taped down the sides where the wires were twisted and sticking up. While this method holds the canvas in place, we’re concerned about the lack of affordable materials that could cover the wire, without the goats chewing it off.

|

|

|

|

|

|

|

Sewing

|

|

|

|

Another method involved looping the mesh around the frame and hand sewing the edges flush against the frame. Similar to the above prototype, four corners of the mesh substitute were cut so that it could wrap around the base frame’s edges. This also keeps the the fabric tightly in place and doesn’t move around when pressure is applied to the center of the fabric.

One concern is our lack of familiarity with the strength of industrial sewing material. Fin weighs around 80 pounds, so even sturdier thread like this Military Nylon Thread might not do the trick.

Another key concern is the amount of time and energy needed to sew the trampoline mesh onto a much larger prototype. The goal is for Leanne to be able to replicate this model multiple times for all the goats at GOA, so we need a solution that is less time consuming.

We watched this dog cot tutorial by Sailrite (the same company we purchased the trampoline mesh from!) to explore additional ways of fastening the mesh onto the frame, perhaps by incorporating a zipper. Though again, this would be a time- and resource-consuming endeavor.

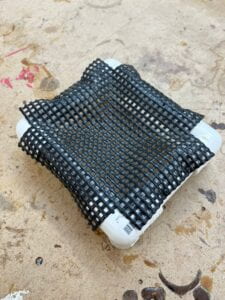

Drilling with Screws

This elevated dog bed tutorial inspired us to consider drilling small screws to connect the trampoline mesh to the PVC tube frame. We first tested drilling into a loose piece of PVC tube, and then onto the small prototype we build last week. The test was successful with one screw, and it held the mesh tightly on. Moreover, Leanne particularly liked this solution, because the tools and materials are cheap and readily accessible.

There are still some concerns, however. One is the head of the screws; it’s possible that Fin could bump into the screw head and hurt himself. A workaround for this is wrapping the mesh material over and under the PVC tubes and drilling from underneath.

We’re also unsure if cracks could appear if multiple sites on the PVC tube are drilled. Moreover, we’re unsure how much weight the frame could hold over time, and if cracks could appear after some time passes. We plan to test these concerns this week with the 15 pound dumbbells.

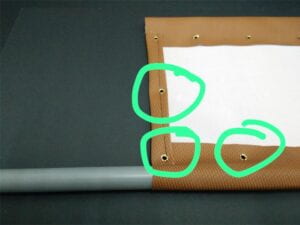

Rivets and Eyelets

|

|

|

This last idea is a modification of the above solution with screws. Instead of the point of connection occurring at the tube, we could instead wrap the mesh around and connect it on the base of the mesh itself (but still close to the PVC tube).

We think rivets and eyelets are interesting fasteners to consider. They essentially achieve the same goal, though eyelets may require us creating holes in the trampoline mesh so they can fasten. However, rivets may fit through the holes on the trampoline mesh and don’t involve any additional holes that could accidentally trap the goats’ hooves and horns.

Additional tutorials we found online that would be helpful are inserting an eyelet and constructing a shoe rack.

Post-Client Meeting

After we met with Leanne to go over these options, we decided screws would be our first choice. After our call, we drilled more 2.38mm screws to hold the trampoline mesh in place from the sides of the PVC tube (given this is a smaller surface area).

We then had one of our team members stand on this small prototype. And it held her in place! We were very impressed with this result and feel even more confident in a larger prototype’s ability to hold Fin’s weight. And the screws are very subtle and didn’t feel very noticeable on the prototype.

|

|

|

|

As for next steps, we will coordinate a time to meet with Leanne at GOA’s farm to construct a larger version for Fin. We plan to bring the rivets and eyelets as backup, but we feel confident in the screws right now. We’re all very excited by these promising options!

Weekly Update 4: 11/8/22: More Rapid Prototyping with Trampoline Mesh

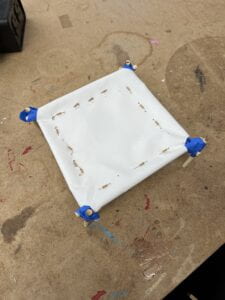

Rapid Prototype: Trampoline Mesh & PVC Frame

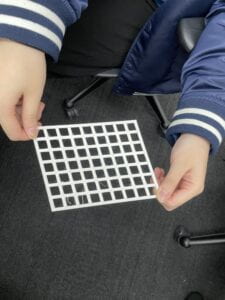

Last week, we placed our first order from Sailrite for the Trampoline Mesh Heavy Duty 24oz.

The sample material we got in the mail is 6in by 6in with a hole size of 2mm by 2mm. When it’s pulled horizontally, the material doesn’t bend or contort. We also tried scrunching the material up in different angles and noted that the material goes back to its original flat form. Moreover, the material feels smooth and is comfortable to touch.

We decided to rapid prototype a small flat base bed with the sample mesh. We built a small cube-like bed with 8 PVC connectors and 10 PVC pipe sections. Then, we used 8 zip ties to secure the trampoline mesh sample to the top of the frame. It’s important to note that multiple zip ties are required to securely fasten the mesh to the pipe edges. Otherwise, the sides of the mesh might fold downwards and lift away from the PVC frame edges. We also noticed that running zip ties through the holes didn’t cause the material to rip, which was a significant obstacle we were struggling with earlier.

To test this prototype, we placed 7-pound and 15-pound dumbbells (separately) to see what happens to the mesh.

|

|

|

The trampoline sample held the dumbbells quite well. Based on this test, we think that trampoline mesh could be the ideal material for Fin. However, our main concern right now is that the holes aren’t big enough to pass through feces. These are some questions we had:

- How do feces affect the goats’ skin?

- Do healthy, non-disabled goats avoid their feces during sleep?

- What is the texture and consistency of the goats’ feces? Would urine wet them?

- If so, do wet feces cause scalds and skin infections? Or is urine the only cause?

- Would adding absorbent bedding like straw be enough to keep the goats dry overnight?

Client Meeting

We met with Leanne today (11/8/2022) to get feedback on our prototype, as well as answers to some of our questions.

- The mesh should prioritize urine filtering out. If we had to choose between smaller holes or bigger holes, we should go with smaller holes. Feces not passing through just makes it grosser to clean, but the trampoline mesh is easy to hose off. Additionally, the texture and consistency of goat feces doesn’t result in urine scalds. Leanne also doesn’t want to risk any possibility of the goats’ hooves getting caught in the holes.

- Fin isn’t able to get up, so his bed specifically needs to have a dip in the center, almost like a hammock, so he doesn’t accidentally roll off. His bed doesn’t need four walls either for the same reason. However, it would be good to have the edges be slightly elevated, so as to prevent any possibility of him rolling off.

- The other goats, who are able to get up on their own, do need a flat base and four walls around their beds. This is so they don’t get up, fall off, and injure their legs.

- Straw isn’t needed for the trampoline mesh beds, because there’s already an effective filtration system in place with the holes. Straw was only used for the pool beds, because there are no holes in this bed, and the straw would’ve absorbed some urine. However, the goats tend to kick and turn in their beds at night, so the straw gets moved around and urine ends up pooling anyway.

- A major concern is having loose zip ties along the pipe edges. These zip ties are rough and can cut into the goats’ skin. Similarly, if the zip ties tear into the mesh, the resulting rough edges can cut skin. We need to find a way to cover the zip ties along the pipe edges. Some ideas we had on call was using grommets to collect the loose ends or testing with the adhesive, leather-y trampoline tape that’s often purchased with the Sailrite mesh.

Next Steps

We plan to meet with Leanne again next Tuesday afternoon. By this meeting, we plan to modify our current prototype to better cover the zip ties. If the prototype is secure, we plan to move forward with purchasing and shipping Leanne the full-sized mesh and instructions for modifying her existing PVC bed frame.

Weekly Update 3: 11/1/22: Material Review and Rapid Prototyping

This week, we filmed our midterm video, which summarizes our visit to the Goats of Anarchy’s farm, as well as our competitive analysis and research findings.

In addition, we continued to add to our collection of secondary research and have begun rapid prototyping materials for the mesh.

Client Meeting

We met with Leanne to discuss the materials we’ve found so far. The following is a summary of the feedback we received:

| Mesh Material | Feedback |

| Trampoline mesh | The most promising! It seems very durable and would be easy to hose down with water or scrub down with brushes if needed. |

| Garden Weed Barrier Landscape Fabric Heavy Duty | We’re open to it! A key concern is the amount of time it’d take for the center of the mesh to dry, since that’s where urine tends to pool the most.

|

| Cat Litter Mat | This would be difficult to string multiple of and to secure onto the PVC crib frame. There is also the concern of how long this would take to dry, since urine and other waste would be sitting inside the pouch for a long time (ideally would take 3-4 hours at max). The ideal mesh would keep dry. The goats might also nibble on this.

|

| Crinoline | This material seems similar to the ABS gutter mesh they previously tested, which ripped easily. This looks dangerous, if the goats’ teeth got caught on it. |

| Intelli-Gel™/Gellycomb™ | We are concerned if the material is too hard. We also don’t know how small the holes are, which could be an issue if it catches the goats’ hooves. We would need to contact the manufacturer, because we’re all unfamiliar with the material.

|

| Shelter-Rite | Similar concern as Intelli-Gel™/Gellycomb™; we’re unsure if the material is too hard. We also learned that the company typically produces material for institutions like airports and building construction sites only. So this material may not be very public in the market. We would need to contact the manufacturer, because we’re all unfamiliar with the material.

|

| TPE Gel Mattress | While this is the most comfortable, the goats will mostly like start eating this. Leanne mentioned that if it’s something that humans can rip off with their teeth, then the goats definitely can. We also discovered that while the material is cheap, the shipping costs are very high. |

| 3D-Printed TPU Mesh | We discussed this option as a custom design. While it works fine, this is still our last resort option, if absolutely nothing on the market works. |

Material Research

Heavy Duty Garden Weed Barrier Landscape Fabric

Inspired by the sports netting, we began to research other fabrics that have pre-built holes but aren’t necessarily popular in animal bedding. We came across this heavy duty garden weed barrier landscape fabric, which is made of polypropylene material. The fabric is breathable and water easily leaks through. Moreover, the material is environmentally friendly, which makes it more appealing as mesh material for Fin’s crib.

A 2.6′ x 100′ roll of this fabric is available on Amazon for $31.99.

Intelli-Gel™/Gellycomb™ & Shelter-Rite

|

|

|

Last week, our class had a tour of the ITP MakerSpace at NYU Tandon. There, we learned about the Material Connexion database, which lists a mix of existing and speculative materials. Given the promising results of our sample TPU mesh, we were curious if similar material already existed. That way, we could potentially save costs on having to custom fabricate mesh from scratch.

The Intelli-Gel™/Gellycomb™ material is interesting for a number of reasons. One, we quickly learned that this material is meant for cushioning. The manufacturers claim that the material’s columns buckle to accommodate body mass. Moreover, the material has a high water resistance and has rubber stiffness. Two properties that we’re flagging, however, is the lack of information about its tear resistance and its low wear resistance (which seems counterintuitive for a cushioning material).

Even more promising is the Shelter-Rite material. It’s a printable PVC coated textile that is flexible and durable. Additionally, Shelter-Rite has high scratch, stain, tear, water, and wear resistance. These properties essentially tick off our requirements for the mesh, most notably the waste drainage and skin and hoof protection pieces.

Rapid Prototyping

|

|

|

|

We recently purchased sheets of the silicone rubber that was mentioned in our competitive analysis. Poking holes into the sheets was relatively easy. However, a significant finding was that once a tear occurred on any of the holes’ perimeter, the sheet continued to rip with ease.

Based on the silky texture of the rips, we believe the fiber construction is prone to being torn easily. We tried to minimize any tension placed on the holes’ perimeters by spacing them further apart. However, we realized that this would be impossible to avoid, because the sheet would need to fasten onto the PVC frame via zip ties looped through the holes on the edges.

As a result, we’ve decided to rule out rubber sheets for mesh. More importantly, an insight we had was that adding holes to flexible material that doesn’t come with holes might not be an ideal solution. This is because the material would be rendered “broken,” since it wasn’t constructed to sustain holes in the first place. Therefore, we’ll begin focusing more on materials that are already constructed with holes.

Next Steps

- Purchase trampoline fabric, garden weed barrier fabric, and PVC tubes to build small prototypes

- Visit B&J in Midtown NYC to discover additional swatches of mesh material

Weekly Update 2: 10/25/22 (Competitive Analysis)

Literature Review

The main issue with the disabled goats at Goats of Anarchy (GOA) is the pressure sores and urine scald. Pressure ulcers, a common chronic wound, are areas of necrosis and ulceration where tissues are compressed between bony prominences and hard surfaces. They occur when the skin and underlying tissue become damaged due to pressure alone or pressure in combination with shear (National Pressure Ulcer Advisory Panel, 2009).

The impact of pressure ulcers and urine scalds are pain, exudate, and odor. The treatment of pressure ulcers is very costly. In humans, according to one study (Zarei E, et al., 2019) it can be up to $1176 per patient. Unfortunately, there are no studies that calculate the cost for goats or animals in general, but if they are using similar dressing techniques in animals then we can project this study to goats and reach the conclusion that it is very costly to treat these wounds.

The process of managing pressure sores starts with evaluating the situation and what is causing the wound. Then manage the wound by modification in the environment, such as: changing the mattress from a normal mattress to an air mattress or egg matters. Also, the occupational therapist would suggest moving the patient repeatedly (Giesbrecht, 2006). Regarding urine scald prevention in humans, they use catheters to prevent the patient from being soaked in urine. This is not the case with goats, there are no catheters for these goats. Therefore, the management of pressure sores and urine scald is different, air and egg mattresses cannot be used because they will end up wetting their bed and causing skin complications. The best option for them would be by using a mesh bed with straw in between two layers of mesh to allow urine to pass through and provide comfort and prevent pressure sores in the disabled goat. According to many farmers, straw makes a comfortable bed for goats in general (Lee, 2022).

Previous DIY Approaches

GOA have attempted numerous solutions before working with our team. We’re highlighting some of their approaches below, which will guide us in establishing user requirements and features to incorporate or avoid.

DIY Approach #1: PVC tube crib frame with gutter mesh

Oftentimes goats will sleep on wooden beds. However, this isn’t a possibility for Fin (and other disabled goats) for a number of reasons:

- The cribs must be light-weight, because they get assembled in the barn during the night and disassembled during the day, so there’s more space for all the goats to roam about.

- The cribs need to be sturdy enough, so they don’t get flipped over easily. As a rule of thumb, if a human can easily flip it over, the goats can as well.

- The cribs must have elevated sides for the goats to rest their heads. However, the crib can’t be too high, because caretakers still need to lift the goats onto them.

- The cribs must be elevated at least 3 inches off the ground, so any overnight waste doesn’t linger inside or on the goats’ skin.

GOA built a custom crib frame out of PVC tube, which meets these requirements. They used zip ties to attach mesh to the frame.

While the holes on this mesh filtered urine and other waste, they often resulted in abrasions on Fin’s skin. Moreover, the material isn’t durable enough to withstand Fin’s movements in the crib, resulting in mesh tears and larger holes that went on to trap his hooves.

DIY Approach #2: Elevated Dog Cot

The elevated dog cot was a comfortable and durable solution in terms of supporting Fin’s weight. Additionally, the cot seemed to be a good height off the ground. However, the cot doesn’t have any holes in it, so urine would pool on the fabric and result in skin infections. Moreover, there aren’t any elevated sides to support Fin’s head and neck. Fin would also nibble on loose-hanging strands, which could result in stomach complications.

DIY Approach #3: Inflatable Pool Bed

The inflatable pool bed is Fin’s latest crib. While the material is much softer, the current framework still results in pressure sores, as well as rashes around Fin’s eyes, caused by his skin rubbing against the elevated edges’ seams. The towel and straw are meant to absorb overnight urine, though Fin still needs to be washed daily in order to prevent the formation of urine scalds.

Commercially Available Products

After assessing GOA’s solutions, we looked into existing materials that could serve as a mattress and/or mesh material.

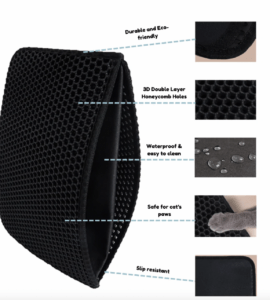

Proposal #1: Litter Mat

Suprecle’s Cat Litter Mat is an easy tool that helps keep litter box areas clean. These mats are typically placed underneath litter boxes; so when cats step off, waste droplets and particles get filtered through the top layer’s holes and into the pouch. When the mat gets heavy, owners can open them up and empty the waste efficiently.

The mat is durable, waterproof, slip-resistant, and soft enough for cats to walk on regularly. While smaller than a standard mattress, it may be possible to tie together multiple mats to cover the base of Fin’s crib.

Some factors to consider are:

- Is the thickness of the mat comfortable enough to bear Fin’s weight? Would we need to place more cushioning underneath the mats?

- Are the holes smaller than an inch in diameter?

- Will Velcro be durable enough to seal any overnight waste? Can the mats be modified with zippers instead?

The original price for a single mat is $49.98, but there is an extended 50% off sale, making it $24.99 to date. The mats can be purchased on the Supercle website.

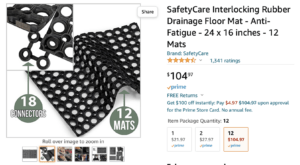

Proposal #2: Rubber floor mats

A key consideration for the mesh model is its ability to connect with multiple meshes, in case we’re unable to find a single piece that spans the base of the crib. We discovered this rubber drainage floor mat from Amazon, which is thicker and stronger than the mesh used for GOA’s DIY Approach #1. Moreover, these mats come with connection joints between each piece/hole, which keeps the structure intact and resistant to tear.

Twelve 24″ by 16″ mats can be purchased on Amazon for $104.97.

Proposal #3: TPE Gel Mattress

We began thinking more critically about the thickness of the mesh, since Fin’s comfort is a priority. We also wanted to consider large products that require little to no attachments, since added weight could impact connection points.

Ali Baba is a popular wholesale merchandise platform that sells items in bulk. There, we came across the above-pictured TPE Gel Mattress. We were instantly drawn to it, because the material is soft, there are holes that run all the way through, and the thickness seems more promising in terms of durability. Moreover, there are various dimensions for these mattresses, so they can be customized to different crib frames, depending on the goat’s size.

While the thickness of the mattress is preferable, we’re concerned if it’s possible for any waste particles to get trapped inside. If this is a possibility, then it’d take much longer to clean the mattresses thoroughly on a daily basis.

Because Ali Baba orders may take some weeks to process, we will be exploring other solutions while the mattress is being shipped.

Around 50 pieces of the TPE Gel Mattress can be purchased on Ali Baba for $58.00.

Proposal #4: Rubber Sheets with Drilled Holes

Rubber is a promising material, because it is waterproof and durable enough to hold Fin’s weight. However, the issue with pre-existing rubber mats with holes is that the holes tend to be very large. From GOA’s experience, the holes cannot be larger than roughly one inch, because the goats’ hooves could easily get trapped, resulting in skin abrasions and tears on the mesh.

A workaround is to create the holes ourselves. While laser cutting isn’t an option (due to the fire hazard), manually drilling holes is. Customized drilling would ensure an appropriate hole size, though a significant drawback is the amount of time and labor needed to drill entire sheets.

Upon discussion of this solution, Leanne from GOA expressed interest in exploring this route. So, we will be purchasing a sample sheet to drill our own holes. Afterwards, we will test the durability of this sheet to see how difficult it is to tear into the material and/or create larger holes “by accident.”

A 12″ by 12″ cut of the silicon rubber sheet can be purchased on Amazon for $7.99.

Additional Proposed Solutions

Based on the research we’ve conducted and the solutions that GOA have already explored, we plan to keep GOA’s PVC tube frame. In addition to fulfilling the most user requirements, PVC tubes are affordable and plentiful, which resolves the concern of reproducibility.

We’re still in the brainstorming phase for mesh material. As described previously, we’ll be ordering the TPE Gel Mattress while we explore alternative DIY solutions. We’re currently drilling holes into silicone rubber sheets to test the material’s durability. In addition, we’re interested in pursuing the following two options:

Ideal Solution: Crinoline Mesh, Straw, and PVC Tube Crib

Our ideal solution would involve using existing materials on the market, so GOA can readily purchase them at a reasonable price.

With this solution, we would like to line the PVC tube frame with crinoline mesh. Then, at the base of the crib, we would place layers of straw. Lastly, we would tie another layer of crinoline mesh on top of the straw, almost like a canopy.

In our consultation with the Center Coordinator at Barnard College’s Design Center, we discovered that sports netting could be another solution to the mesh design challenge. Some specific materials we discussed were:

Nylon mesh. The holes are very small but should filtrate well, even if we layer multiple pieces. They are easy to purchase in bulk. Black nylon mesh can be purchased on Amazon for $7.99 per yard. |

Gymnasium netting. Rope-like in texture but very durable. However, the goats may end up nibbling on this. A 14′ by 14′ piece of this sports netting can be purchased on Amazon for $159.98 |

Trampoline mesh. Very durable and meant to withhold a lot of weight, since they cover the base of trampolines. It’s similar to nylon mesh. This Trampoline Mesh Heavy Duty 24oz Black 71″ can be purchased on Sailrite for $75.95 per yard. |

Lacrosse netting. Similar to gymnasium netting, the texture is rope-like but the holes are still small. There may be some concerns of the goats nibbling on it. We can invert the model of a lacrosse net for the structure of the PVC tube crib. The Net World Sports 6ft x 6ft Regulation Backyard Lacrosse Goal can be purchased on Amazon for $159.99, which includes the steel frame. |

Crinoline mesh. Very durable and easy to hose down with water. The holes are also very small. This white crinoline fabric can be purchased on Amazon for $6.99 per yard. |

Based on these options, we believe that crinoline may be the best mesh option. We believe the material will be durable and comfortable for Fin to lie on. Moreover, the holes are very small and it’s both easy and affordable to purchase. Moreover, we can easily zip tie the ends of the crinoline sheets to the side edges of the PVC tube crib, which GOA has already built.

In addition, we believe a crinoline mesh and straw layer will cause the least interruption with GOA’s daily activities. Straw is regularly used on the farm, so they would have a steady supply available. This would work out well, because straw is an absorptive material and could catch waste that gets filtered through the crinoline mesh, which could minimize the amount of drainage that ends up on the barn floors. Additionally, crinoline is very easy to hose down, so the GOA caretakers could wash the crib regularly (should there by any buildup) without detaching any of the pieces. Lastly, the mesh and straw’s compatibility with the PVC tube frame will make it easy for the caretakers to transport and disassemble.

Alternative Solution: 3D-Printed TPU mesh with Box joints

|

|

If all other methods fail, we’ll consider the 3D printing route. In this approach, we would need to produce large prints of TPU mesh with box joint locks. The benefits of this approach is having more precise control over the size of the holes and having a customizable system for joining multiple pieces of mesh. The box joint system would be ideal, because it requires having thumbs and applying force in opposite directions, which goats can’t do (in theory).

However, there are some noteworthy drawbacks to consider. This solution would be the most customizable, which means that it might not be easy to reuse a crib with other goats. Additionally, the 3D printers that we have access to at NYU’s MakerSpace can only print small samples, and we would need larger pieces to connect the least amount of material as possible. This leads to an affordability concern, because having larger prints made at an industrial scale can easily become very expensive. Lastly, we still have the same question as to whether or not increasing the thickness of the mesh would compromise the efficacy of waste filtration.

further consultations

There may still be countless other options for mesh material. To learn more about the possibilities, we plan to have consultations with other animal experts in the local area, such as caretakers at the Bronx Zoo and Queens Zoo.

next steps summary

We will be moving forward with the following:

- Drill small holes into silicon rubber sheets (commercial proposal #4)

- Assemble a PVC tube frame crib with crinoline mesh and straw (ideal solution)

- Purchase a TPE gel mattress in the meantime (commercial proposal #3)

- 3D print TPU mesh with box joints (alternative solution – our last resort)

- Set up material consultations with other local animal caretakers and experts

References

Zarei E, et al. Incidence of pressure ulcers in intensive care units and direct costs of treatment: evidence from Iran. J Tissue Viability 2019;28(2):70–4.

National Pressure Ulcer Advisory Panel, The European Pressure Ulcer Advisory Panel (NPUAP/EPUAP). Prevention and treatment of pressure ulcers: clinical practice guideline. Washington DC: NPUAP; 2009. p. 16e20.

Giesbrecht E. (2006). Pressure ulcers and occupational therapy practice: a Canadian perspective. Canadian journal of occupational therapy. Revue canadienne d’ergotherapie, 73(1), 56–63. [https://doi.org/10.2182/cjot.05.0011](https://doi.org/10.2182/cjot.05.0011)

Lee, A. (2022, May 1). *7 best bedding options for Your goat*. Farmhouse Guide. Retrieved October 24, 2022, from https://farmhouseguide.com/bedding-options-for-your-goat/

Weekly Update 1: 10/18/22 (Goals)

TEAM NAME

We brainstormed our team name while we were at NYU Tandon’s MakerSpace on 10/17/2022. While we were waiting for some of our prints to finish, we sat together to research potential names. We were keen on choosing something related to the project (ideally something punny as well). Some names that we found online were Goatie Homie and The Cozy Goat. We started to notice a similar trend; we wanted the team name to be related to comfort, as we’re designing cribs for our clients. Goats Comfort became a contender. But as we thought more about names that didn’t have “goats” in it (given “Goats” of Anarchy already did), we branched into other related characteristics. That’s when we arrived at The Cozy Bleats. We voted on our options and ultimately decided to go with that.

TEAM RESPONSIBILITIES

It’s important to note that everyone in The Cozy Bleats is a designer and researcher. These are core aspects that ensure a democratic approach to making design choices.

In addition to these core roles, we each specialize in the following:

| Team Member | Responsibilities |

| Alaa | OT Specialist – Alaa oversees design requirements that pertain to the goats’ health impacts, such as pressure sores and urine scalds. |

| Maggie | Product Developer – Maggie oversees the 3D modeling and development of original prototypes we fabricate at NYU Tandon’s MakerSpace. |

| Rainee | Product Developer – Rainee contributes to the development of original prototypes at the MakerSpace. |

| Simone | Team Communicator – Simone manages our email exchanges with Leanne and schedules our meetings, ensuring we meet core deadlines on our project timeline. |

| Syeda | Project Writer – Syeda is in charge of synthesizing meeting notes, research, and feedback/insights from Leanne. She oversees content writing for The Cozy Bleat’s webpages. |

schedule

Our goal is to meet twice a week as we work towards our objective. One meeting will take place on Tuesdays at 2:00 PM, where members of The Cozy Bleats can meet with Leanne. During these meetings, our goal is to ideate on the core design requirements of the crib and mesh. Over the weekends, members of The Cozy Bleats will do additional research based on what we cover in our Tuesday meetings and ideally prototype additional samples at NYU Tandon’s MakerSpace.

project description

The Cozy Bleats is collaborating with Goats of Anarchy to redesign cribs for disabled goats. Our objective is to develop 1) a crib frame and 2) a waste-filtration mesh that prevents the development of pressure sores and skin infections, such as urine scalds.

Goats of Anarchy is a non-profit sanctuary for paralyzed goats and other animals, offering them a second chance at life. These goats rely on round-the-clock support from the farm’s caretakers, ranging from physical therapy to bedside care.

For the scope of this project, we will be centering our crib redesign around Fin’s needs. Fin is the largest and heaviest goat on the farm and currently uses a wheelchair to navigate. Moreover, he relies on the caretakers to lift him onto his bed. Fin often develops urine scalds and irritation around his eyes, caused by the pools of urine and waste that accumulate in the beds overnight. Moreover, softer cribs like pool beds have seams that rub against Fin’s eyes, resulting in rashes. Thinner meshes have proved to be uncomfortable and susceptible to breakage as Fin moves and digs his hooves overnight. Therefore, our design challenge is to develop a crib that is both lightweight for the caretakers to disassemble during the day and sturdy enough to hold Fin’s weight and filter out waste.

The development of this crib and mesh may very well be the first of its kind. We are addressing a unique need that impacts countless disabled goats in the U.S., given there is no known solution to the comfort and filtration pieces to this design challenge. As such, a successful crib may compel farmers everywhere to support disabled animals in sustaining a healthy and happy lifestyle.

tools and expertise

Our primary tool and skill to leverage for this project is 3D fabrication. The crib mesh factors in a number of requirements, which may necessitate designing and printing a custom mesh. Thankfully, several members of The Cozy Bleats are familiar with 3D modeling and printing, so we are able to fabricate prototype samples. However, the MakerSpace that we work in lacks 3D printers that can print industrial-sized meshes. As such, when it comes time to fabricating larger meshes for the goats to test, we may need to seek alternative printing sites that can accommodate our needs.

A critical design requirement we’re thinking about is the thickness of the mesh. This needs to be strong enough to bear the goats’ weight for consecutive hours. In the event that 3D printing a thick mesh with holes is unsuccessful, we may need to learn advanced laser cutting skills with alternative materials that our local MakerSpace cutters don’t currently offer.

project timeline

| Item | Date |

| First group meeting | 09/25/2022 |

| First meeting with GOA | 10/01/2022 |

| Desk research | 10/02/2022 – 10/05/2022 |

| Second group meeting | 10/05/2022 |

| Second meeting with GOA (moved to email b/c of schedule conflicts) | 10/05/2022 |

| Mesh Sample Prototyping at MakerSpace | 10/15/2022 |

| Third group meeting | 10/18/2022 |

| Prototyping Session | 10/19/2022 – 10/24/2022 |

| Midterm Presentation (1st weekly update & competitive analysis) | 10/25/2022 |

| Fourth meeting with GOA | 10/30/2022 |

| Iteration <> Feedback | 10/31/2022 – 12/06/2022 |

| Final Project Presentation | 12/06/2022 |