Links to planning:

Link to artistic statement

Link to presentation

Our project represents the intersection of future-scenario speculation with present-day resource equity. Using entirely repurposed materials, we sought to connect these issues by creating completely sustainable light sources that are universally accessible. The intention of this project was to unite zero-waste design with art by upcycling plastic bottles into reliable, aesthetic light sources accessible to all.

This product combines plastic waste diversion with directly practical applications for adapting to climate change. Extreme weather events, flooding, droughts, communicable disease outbreaks, and natural disasters will be amplified in the future, and it is likely that access to electricity will often be disrupted. In anticipation of these obstacles, we wanted to create a prototype for a solar-powered lantern to help mitigate and adapt to the challenges of climate-related disaster. Future iterations of this item could provide a reliable source of lighting when electricity is disrupted or when power systems fail. This consists of a single plastic bottle filled with water and bleach, which refracts sunlight through the interior of a home. Our design, cylindrical lanterns made out of recycled plastic with cutout designs, diffracts light in a pattern.

The current light source iteration does not emit enough light to illuminate an entire room, but future iterations could use larger water bottles and be vibrant enough to project the shadow design throughout a home.

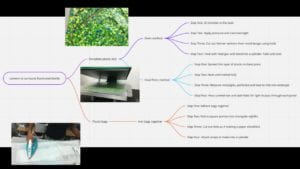

shredded HDPE bottle caps of different colors

Oven Method:

Successful fitting into mold, with the raised portions of the mold being thinner than the others, which enabled cutting slots through the thin portions using a knife

The top burnt faster, likely because there was a metal tray beneath the bottom, so it wasn’t subjected to as direct of heat from the oven

We heated the sheet with a heat gun until it became malleable, then carefully curled it into a cylinder using heatproof gloves

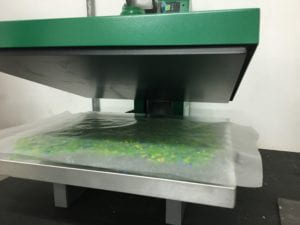

Heat Press Method:

holes were made with a heat-gun-warmed screwdriver to create designs

The biggest challenges were dealing with the rigid thickness of the plastic, making it difficult to cut through. It was also a challenge shaping it with a heat gun without entirely melting the thin parts of the material. For both the heat press and ironing methods, the paper stuck to the plastic and was difficult to remove.

Fused Plastic Bags Method:

Slits were made into the eighths-folded triangles of the material

I am very pleased with the success of this project, which fulfilled our goals of functional upcycling, sustainability, zero-waste design, visual aesthetics, and novelty. Through the tangible experience of building this, I learned the extensive potential of restructuring and redefining plastic. The skills of working with tools, shaping a material, and solving problems were very fulfilling, and I hope to incorporate plastic upcycling into future projects.

Many development initiatives like the Liter of Light undermine the dignity of those being “helped,” and this was echoed in the existing Liter of Light programs worldwide. This project attempts to intervene by turning something from an ordinary plastic bottle into something of art, created specifically to bring aesthetics and comfort to those most affected by climate-related disasters. The idea of Cradle-to-Cradle design resonates here, and even though this plastic product does have a finite life cycle, this adds one more valuable step along the way by upcycling rather than downcycling. This mitigates the production of additional materials like those to create a lightbulb or formal lamp, for which technical nutrients are ultimately lost. Transforming bottle caps and plastic bags into something more valuable disrupts cradle-to-grave-minded processes of downcycling. This is also a nonspecific product, and could easily be repositioned and repurposed even generations later.

Final products illuminated at night:

Movie on 09-06-2021 at 9.02 PM #2

CBC47ACD-F571-42A1-8A8D-2D8292A38BE4

A part of me remains uncomfortable with the idea of how many plastic bottles would have gone into this product — and how much plastic would be left unaddressed. We used probably fifty bottle caps, but each one of these came from a plastic bottle, the volume of which far exceeds the bottle caps themselves.

My discomfort with plastic continues to stem from our lack of research and knowledge of its long-term implications on human and environmental health. Plastic has not been around long enough for scientists to derive causative conclusions on any heritable, epigenetic, or genotoxic effects. As we learned in the readings (especially in Plastic: A Toxic Love Story), the plastics industry and resin conglomerates have abundant resources and networks to suppress any investigations into their products’ hazardous effects. Even though melting plastic is merely a physical reaction, we cannot say for sure that doing so does not release fumes, or that the accidental burning releases chemicals of which we cannot possibly know the long-term effects yet. Thus I worry about this, because there are so many materials we’ve thought were harmless in the past, only to find out that they caused lasting damage.

With that being said, this class shows the importance of acknowledging the truth that plastic is our current reality, and we may need to work with it rather than against it. As it continues to remain a huge ecological burden on habitats worldwide, fusing or melting plastic into new forms is a valuable skill that will prove increasingly vital. I was pleased with our products, and I would love to build on more advanced production methods in the future.

Future iterations should balance being thin or light enough for light to pass through, while having dark/thick portions to create shadowed designs. It would also be useful to use the CNC to make gradiated cutouts.

This was a valuable experience in generating a product from ideation to prototyping and seeing the final products illuminated in the dark was immensely gratifying. I wish we had used the CNC, laser engraver, or 3D printer, as these are increasingly essential skills for innovation. It would also be valuable to perform life-cycle assessments of this material and of water bottles that went into its production, and to try repeated trials with different types of plastic or biological additives that could make it more malleable or easier to work with.

One of the strengths of our product is that very little energy input is needed to create it, and then it offsets future energy consumption by providing light without electricity as an input. Plastic is diverted from end-of-life incineration, landfilling, wildlife damaging, and energy-intensive down-cycling. This is more circular than traditional linear economies, with value added to materials that otherwise would have been wasted.

Milestone 1: Mood Board

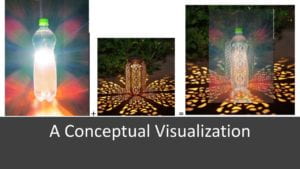

Milestone 2: Conceptual visualization

Our process consisted of constructing three separate lantern casings and evaluating the strengths and weaknesses of each.

(please see presentation for better-quality image)

Our experimental design process consisted of three distinct prototypes, each utilizing different techniques. The core of our lantern is a simple, clear bottle filled with water, which glows luminous when a flashlight is applied to it. To make the cylindrical lantern-cover that surrounds the bottle and turns it into a dignified piece of art, we successfully employed three different methods. The first method used fusing of plastic bags into one material, then folding and cutting out slots to create a ‘paper snowflake’ effect. It was difficult to cut through the plastic with the small pair of scissors we could find, but otherwise this turned my childhood love of making paper snowflakes into a viable form of sustainable creation. It is worth noting that for this design, the cut-out negative space portions were indeed wasted: not as a whole plastic bag but as smaller pieces that will likely be incinerated or float around a landfill. Future iterations could use these smaller pieces to fuse together more elaborate sheets of reclaimed plastic bags, such as by decoupaging them into patterns.

The second category of lantern prototypes used shredded HDPE (#2) plastic bottle caps. For the Oven Method, they burnt slightly and formed a thick layer we later cut out slits from (which was a very difficult task), then gradually heated with the heat gun and manually curled into a cylinder.

The Heat Press method was similar, but we perforated the outlines of four rectangles which we then folded into a rectangle/cylinder shape, and Fanisi then hot-glued them together.

Design: Our actual production deviated slightly from our intended project plan linked here, because we could not use the CNC machine and the heat gun enabled us to curl hard plastic into a cylinder rather than having to create multiple rectangular panels and then unify them together into a polygon.

In the future, we should experiment with creating a roof-mounted bottle lantern model, which would remain watertight sealed in the roof, while still allowing maximum light to pass through. Many contexts also utilize solar panels, which would be immensely beneficial– but the downside is that it requires technical nutrients and raw materials that ultimately could be wasted, or that damage ecosystems in the production process for the solar panel.

Sources:

Solar Bottle Lamps: Water + Bleach = Light

Citations for mood board:

Disasters: https://www.wionews.com/india-news/double-crisis-natural-disasters-dont-stop-for-coronadvirus-308890

Garden bottles: https://www.thisiscolossal.com/2013/02/urban-vertical-garden-built-from-hundreds-of-recycled-soda-bottles/

Plastic Chandelier: https://www.bouf.com/vendors/sarah-turner-eco-art-design/

Bottle top lamp: https://smartrecycleideas.wordpress.com/2014/08/13/creative-plastic-recycling-ideas-for-plastic-straws-1/

Rubble image with tree: https://www.weforum.org/agenda/2019/12/extreme-weather-climate-change-displaced/

Colour palettes: https://www.color-hex.com/color-palette/45299 and https://www.schemecolor.com/earthy-green-and-brown.php

Street light: https://www.ready.gov/power-outages

Liter of light street light: https://revolve.media/circular/liter-of-light-repurposes-bottles-rural-communities

Leave a Reply