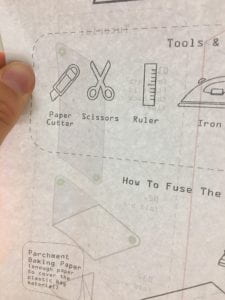

This is an immensely positive product to create: it prevents plastic bags from floating out of trucks, into habitats, disrupting marine ecosystems, and requires very little net energy input to create a coin purse. Wallets are something used by essentially everyone, and this represents a way to make a unique, customized and conversation-starting-but-still-aesthetic wallet individually — without a large amount of energy and requiring minimal raw materials. Plastic bags are melted together using an iron, which connects the bags to create a reinforced multilayer material that can then be cut and folded for a durable, water resistant triangular wallet. The texture of the melted plastic material reminded me of some reusable shopping bags sold in grocery stores, and this demonstrates how this is not just an unnecessary creation but a viable way to disrupt our reliance on single-use plastic bags. The skills of creating reinforced, durable plastic can be transferred to repurposing the plastic bags one has accumulated, then could potentially turn them into long-lasting handmade reusable bags by expanding on these techniques. When I was about 10 years old I created coin purses out of a cut-out and folded template for orange juice cartons, hoping to start my own tiny business selling them. This didn’t work as well as this plastic bag variety because coins would easily fall out, but this kind seems more secure and reliable. It only requires ironing the plastic bags together, using electricity to generate heat, and then using pins to connect them.

Hypothetically an old-fashioned fire-heated iron could be used if it’s less energy intensive, and another kind of repurposed snaps could be made to make the components entirely zero-waste materials.

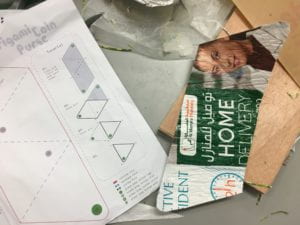

Fanisi and I used this method to create one prototype of our final project lantern, since the material is thin and flexible enough that it can be cut out into designs and bent as needed. I had difficulty figuring out how the snaps worked, and initially put two non-connecting pieces together and couldn’t seal it on my first attempt. I tried to pry them apart so it didn’t work; so we ended up hot-gluing them together. By the time I made the final wallet, I figured out how they worked. Initially, I cut out the material by tracing the template but did so backwards — the plain side of the material would have been the exterior. I then read the instructions through the opposite side of the page by holding the tutorial paper up to the light so I could make the mirror image of the diagram in the instruction paper.

Holding this up to the light enabled me to see the mirror image of the instructions on the other side so I could use the other side of the material to create the exterior I wanted

I would love to repeat this with different methods of closing or snapping the wallet together so it doesn’t require snaps as raw materials. I also wish I had a better selection of plastic bags, because the bag I had included some random model’s face and wasn’t as aesthetic as this has potential to be. I would like to experiment with different types of plastic bags and try different methods of collaging them together to make even more unique and artistic designs. I also would love to try the method in the video we saw in class where they made an entire tote bag; this could be very useful for larger-scale plastic bag mitigation.

I’m glad you were able to make it!