Lab report – bio-materials

name: Fanisi, Max, Ward

e-mail: fm1581@nyu.edu , mab1312@nyu.edu , whm263@nyu.edu

Material: We made biodegradable plastic with recipes that use potato starch and agar-agar powder. The outputs were materials that mimicked some of the properties of plastic.

Introduction or Purpose:

The purpose of this lab was to create plastic out of materials such as potato starch, corn starch gelatin, and agar agar. For this experiment, my group and I decided to go with potato starch and agar agar. We did this experiment to learn how to create biodegradable plastic because it is a better material than regular plastic that would help save our planet and get rid of noncompostable plastics. Our hypothesis was that if we put these ingredients together in a certain way then we would create biodegradable plastic. During the experiment, we found out that the different materials we used created slightly different biodegradable plastics. The agar agar dried quicker than the potato starch and the potato starch had a harder element to it. Doing this experiment we mixed our main ingredient with glycerol, water, and vinegar and we also heated it up while stirring.

Ingredients and Amounts:

Recipe: Potato starch:

- 160ml water

- 15ml vinegar

- 6gr glycerol

- 10gr potato starch

Recipe: Agar Agar:

- 119.6ml water

- 13.52gr vinegar

- 2.08gr glycerol

- 4.42gr agar agar powder

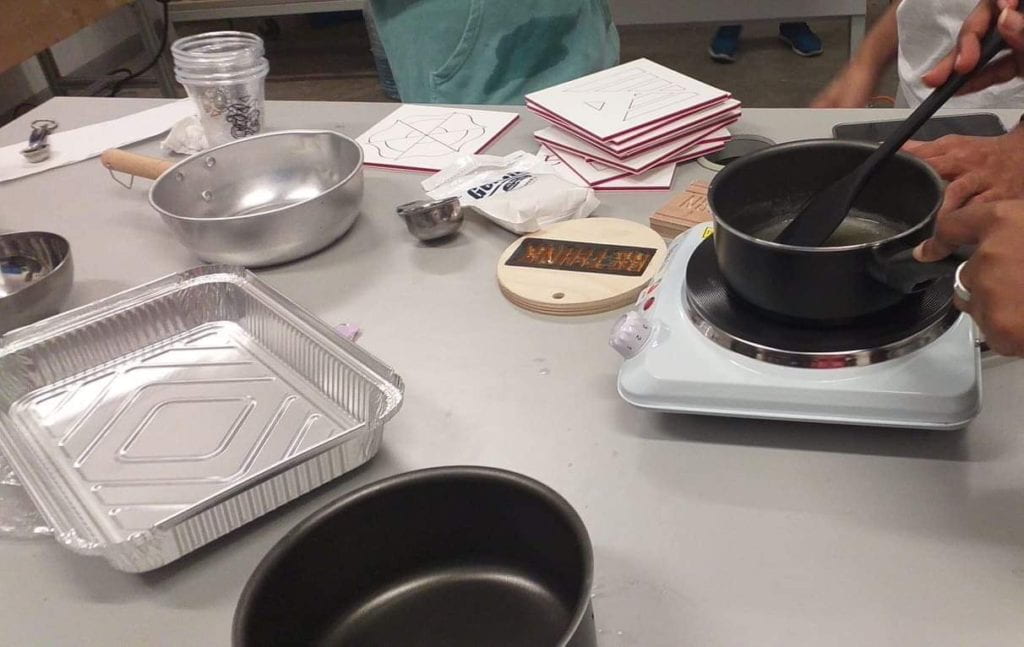

Tools:

- Measuring cups

- Mixing spoon

- Cooking pot

- Single stove

- Aluminum pan

Methods:

- Gather the materials/ingredients needed to create the biodegradable plastic. For any desired conversions (since we used measuring cups) you can use the linked website.

- In a clean pot pour the water, glycerol, and potato starch and mix them until the starch and glycerol have dissolved into the water. Do all of this before putting the pot onto the hotplate.

- For the potato starch turn the hotplate to high heat ( and for the agar use medium heat/85⁰C)

- Place the pot on the hotplate and stir continuously:

- For the agar-agar stir at medium heat for 10 minutes at which point the solution should be viscous. However, do not let it boil over.

- For the potato starch just keep stirring until bubbles start to form in the pot. After bubble formation, mix for 2 more minutes before removing the pot from the hotplate.

- Once the pot is removed from the stove add the vinegar to the mixture and stir thoroughly.

- Put the plastic mixture onto a mold tray and move it around to make sure it is evenly distributed across the surface of the mold.

- Put the setting plastic mixture in a cool and dry space to firm up for 24 hours.

Picture of Setup:

Results:

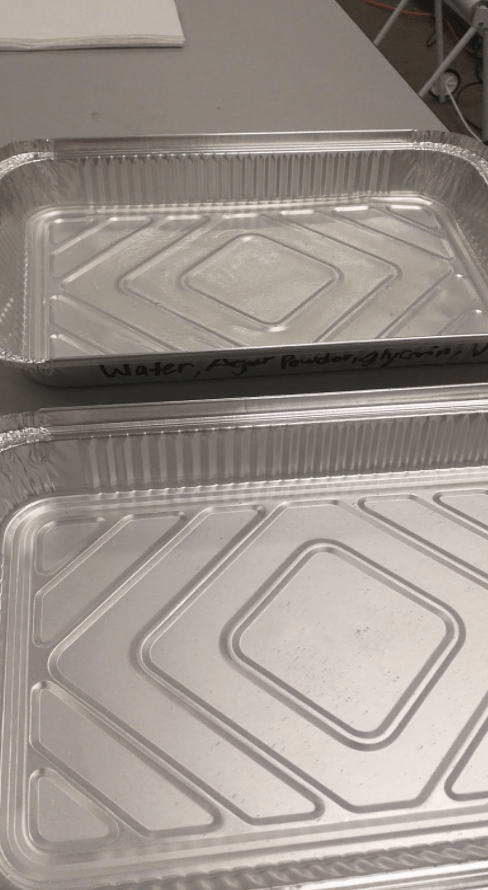

The tray at the top is the agar-agar plastic and the bottom tray is the potato starch plastic.

Physical aspect:

We did not have the chance to fully inspect the material after it had finished curing but upon basic inspection. The material was clear, almost see-through. The agar agar recipe was more transparent than the potato starch and the aga-agar also solidified quicker than the potato starch plastic.

Material observations according to external factors or changes over time:

For the potato starch plastic, the mixture started off more opaque but steadily became more translucent as it was heated and stirred.

Conclusions:

Our experiment to create biodegradable plastic was a success and our hypothesis was accepted. We completed the experiment smoothly and did not come across any struggles while using either the agar agar or the potato starch. This means that the materials we used could be further developed to create plastic items and that even regular people with limited scientific training can do this too. Such accessible plastic recipes allow us to be more planet-friendly and create DIY or industrial plastics without worrying about where they will end up and how long it will take to decompose or if it ever even will.

— UPDATE —

Curation Time

Agar:

- The time spent on the hotplate was around 12 minutes at medium-low heat for the agar-agar.

- Time taken to partially solidify (on the surface) was quite quick: 10 minutes.

- Time left to fully dry out: 24 hours in a cool, dry environment.

Potato Starch

- Time spent on the hotplate was around 8 minutes at high heat. After removing the heat another 4 minutes (with constant stirring) was used to ensure that all the starch was dissolved together with the vinegar.

- Time taken to partially solidify was much longer than agar ~ 20 minutes.

- Time left to fully dry out: 24 hours in a cool, dry environment.

Plastic Outcome:

Physical aspect | Material observations according to external factors or changes over time:

The agar-agar bioplastic came out as a thin, lightweight but quite sturdy plastic. However, because of its thinness it was hard to take out of the tray without tearing it up (as seen in the third picture above). There is little change on the consistency of this bioplastic overtime (we checked the plastic again after another 24 hours), like due to the strength of the plastic.

The potato starch came out similar, except there were a couple of small insects that got stuck in the plastic while it was drying, which made it less aesthetically pleasing to look at. The potato starch plastic was also softer that the agar-agar plastic, meaning we could not stretch it as much as the agar plastic (otherwise it would break).

Additional Conclusions after seeing results:

Our outcome was a range of clear bioplastics with different consistencies. When putting the plastic in the mold we spread the plastic mixtures extensively across the mold, which is probably a reason for the thinness of the plastics (as well as the low volume of the plastic mixture). And since both bioplastics were thin, it was interesting to learn which “thin bioplastic” was stronger than the other. In this case the agar-agar was stronger that the potato starch (when thin), however maybe at higher levels of thickness, the potato starch may have produced the stronger plastic. Evidently, this experiment allowed us to learn that the agar-agar bioplastic has comparatively higher tensile strength when made thin and it may be the most suitable for products like: decorative curtains or clear plastic sleeves.

Leave a Reply