Lab Report – Bio-Materials

Names: Roba, Pangna, Mohammed

E-mails: rgo227@nyu.edu, ps3471@nyu.edu, maj596@nyu.edu

Part 1: Gelatin

Material: Gelatin

Introduction

In this lab, we will be attempting to create bioplastics from two different materials. In the first part of the lab we used gelatin as our primary material, whereas in the second part, we used agar-agar as the primary material to make our plastic. The purpose of this experiment was to check if it was possible to create a durable plastic-like material from the two aforementioned source materials, using basic ingredients that are commonly accessible to us. This is to ensure that such a process would not be expensive to carry out.

Ingredients and Amounts:

- 180 ml water

- 10.8 grams glycerol

- 36 grams gelatin

Tools:

- Stove

- Cooking Pot

- Measuring spoons

- Plastic cup

- Aluminium container for the mold

- Spoon

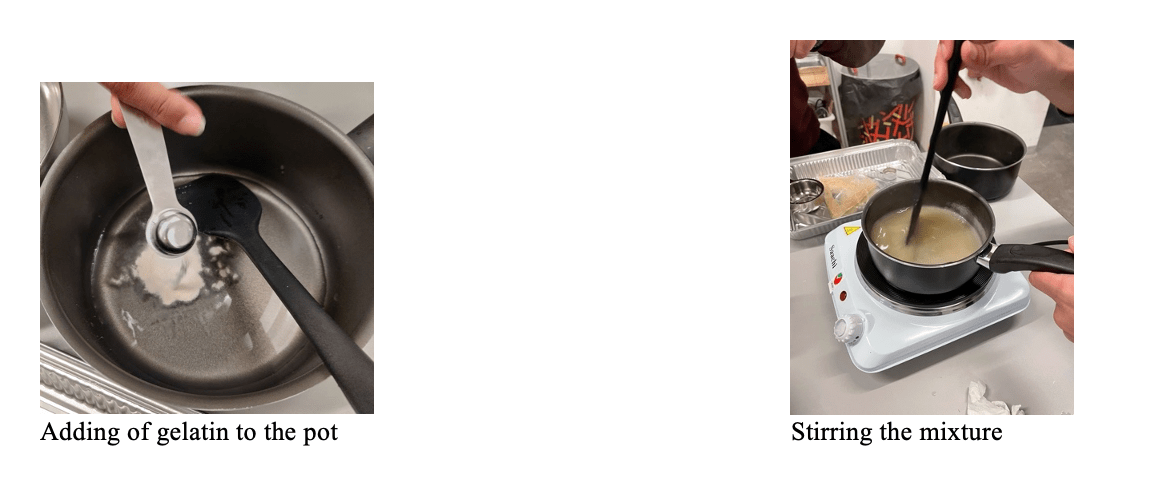

Method:

- Add the appropriate amount of water, gelatin, and glycerol into a cooking pot. The measuring spoons’ units may be in mL and dL, so convert the amounts in grams to those appropriate units if required.

- Place the cooking pot over the stove.

- Change the heat setting of the stove to medium heat and gently start stirring the mixture in the cooking pot until the gelatin dissolves and the solution starts to thicken.

- Remove the cooking pot from the stove and remove the froth with a spoon if there is any and discard the froth.

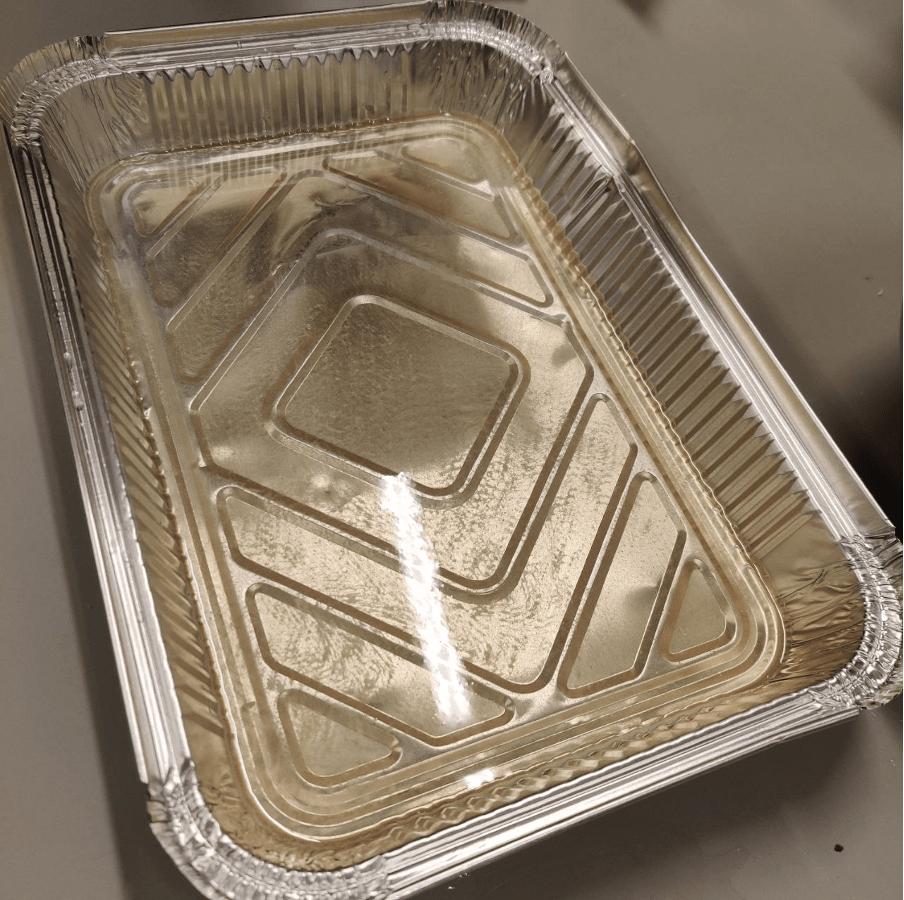

- Pour the mixture into the mold container.

- Wait till the mixture cools down and solidification of the mixture can be observed.

Curing time and temperature:

- Time required to stir the mixture until gelatin dissolved and thickening occurred: 15 minutes

- Temperature setting of the stove: the stove was set at setting temperature no. 4

- Time given for the mixture to cool down: 2 minutes

Results:

The end result after stirring the mixture and letting the mixture cool down for about 2 minutes:

Physical aspect:

The final product was flexible and mostly transparent. It had a yellowish tint to it and felt like any conventional plastic.

Observations:

Right after the mixture was taken from the stove, the mixture felt jelly like, however, as the mixture was left to cool down, the mixture started to solidify and become comparatively more rigid.

Conclusions:

We were able to create a plastic like alternative using a biomaterial, thereby succeeding in making a bioplastic. One postulation for why the final product was not completely transparent could be that the ingredients did not completely dissolve, leaving traces of those materials in the final product.

Part 2: Agar Agar

Material: Agar Agar

Ingredients and Amounts:

- 119.6 ml water

- 13.52 grams of vinegar

- 2.08 grams of glycerol

- 4.42 grams of agar-agar

- 5 ml of blue food coloring

Tools:

- Stove

- Pot

- Measuring spoons

- Plastic cup

- Aluminium container for the mold

- Spoon

- Timer

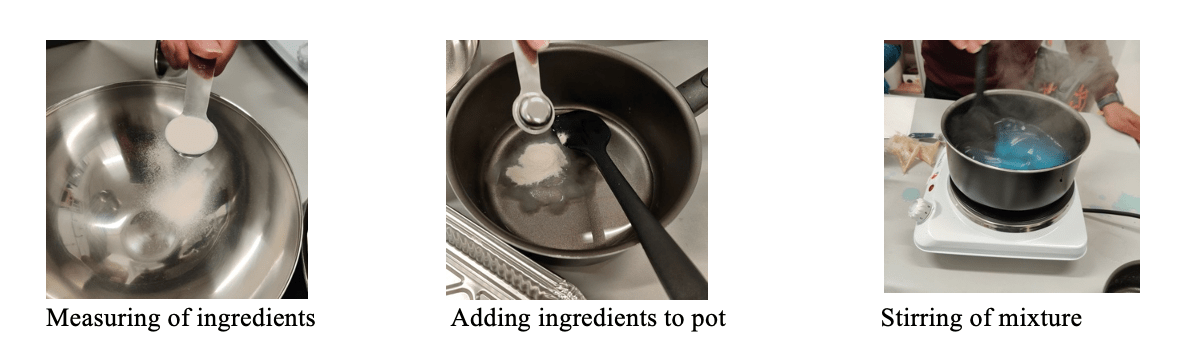

Method:

- Add the appropriate amount of water, agar-agar and glycerol into a cooking pot.

- Place the cooking pot over the stove.

- Change the heat setting of the stove to medium heat (85ºC) and gently start stirring the mixture in the cooking pot for 10 minutes.

- Add blue food coloring to the mix

- Remove the cooking pot from the stove and add vinegar to the mixture.

- Stir the mixture well so the vinegar dissolves.

- Remove the froth with a spoon if there is any and discard the froth.

- Pour the mixture into the mold container.

- Wait till the mixture cools down and solidification of the mixture can be observed.

Curing time and temperature:

Temperature setting of the stove used: 4

Results:

The image of the end product after the mixture cooled down is provided below.

Physical aspect:

The physical properties of the end product include a clear blue color and flexible to the touch. The mixture seems to have a jelly-like feel to it.

Observations:

As we were mixing the mixture, while it was placed on the stove, we observed that the mixture was becoming denser and could also observe the formation of froth.

Conclusions:

We succeeded in procuring a plastic-like substance in the second part of the experiment, thereby successfully proving our hypothesis that it’s possible to make bioplastics using ingredients that are commonly found at our homes. We did this by analysing the material properties of the plastic once it is cured and removed from the mold to test for similarities with conventional plastic.

UPDATE ON THE FINAL PRODUCT AFTER JUNE 3 2021 LAB

Here is a picture of the final products after few days of curation. As can be seen from the picture, both the materials showcases stark similarities to conventional plastic, they have the same texture and feel to it. Our group was successful in ensuring the consistency and color of the products were just as we intended it to be and therefore we can conclude that we were able to successfully build plastic-like alternative from bio materials.

Leave a Reply